Tightness performance detection test tool and detection method for main driver of shield machine

A technology of sealing performance and main drive, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of the fluid, can solve the problems of main bearing damage, loss, shield engineering influence, etc., to ensure Safety, the effect of reducing the risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the scope of protection of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the patent scope of the present invention and the content of the description are still within the scope of the patent of the present invention.

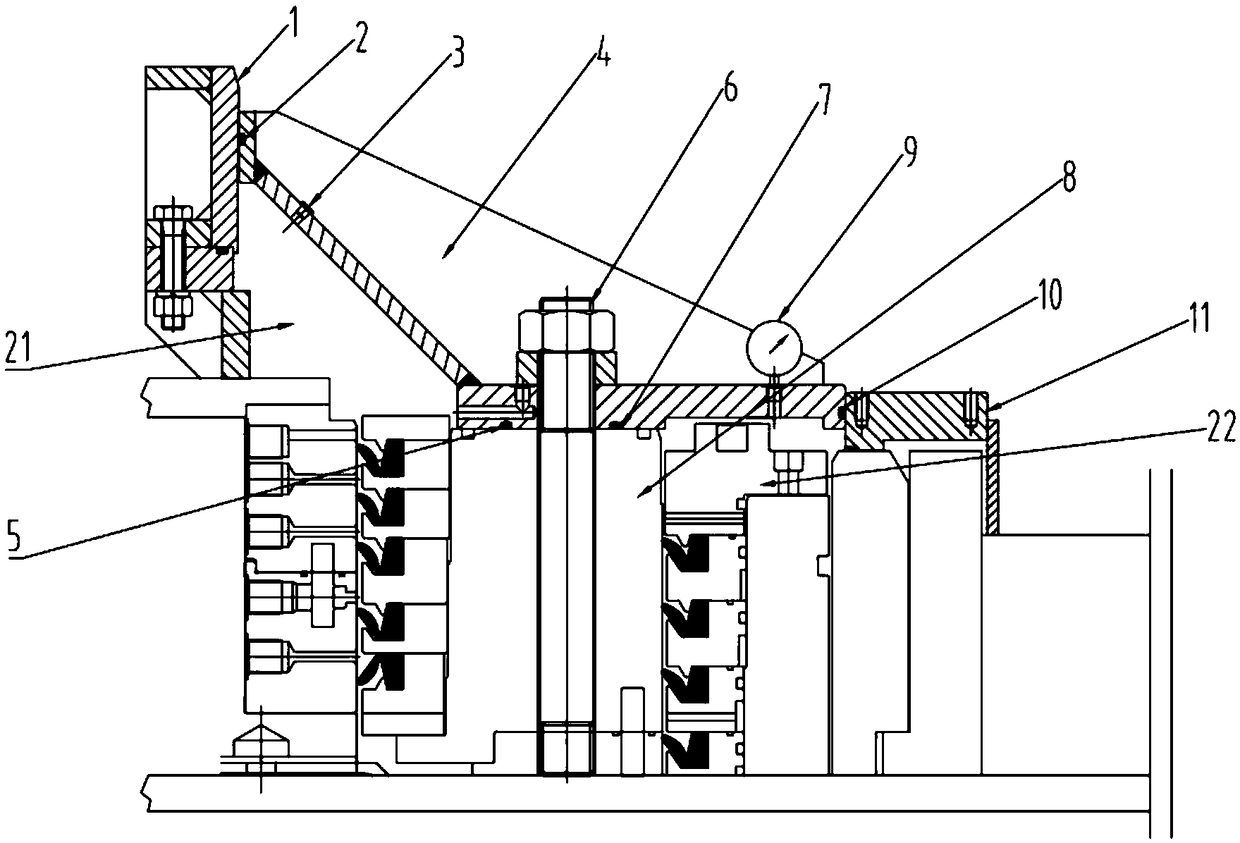

[0018] Such as figure 1 As shown, it is a shield machine main drive sealing performance test tooling according to the present invention, including a tooling sealing ring 4, an O-ring, a stud 6, a plug 3 and a pressure measuring device 9. Before testing, install the tooling sealing ring 4 on the main drive rotary body 8 between the outer sealing flange 11 of the soil bin and the inner sealing wear ring 1 of the soil bin, and use the double-ended stud 6 to rotate the tooling sealing ring 4 and the main drive The body 8 is closed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com