Method for predicting residual lives of heat meters based on multiple degradation sample data fusion

A technology of life prediction and sample data, which is applied in the field of equipment safety, can solve the problem of low life prediction accuracy of heat meters, achieve the effect of facilitating subsequent data analysis and reducing training time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

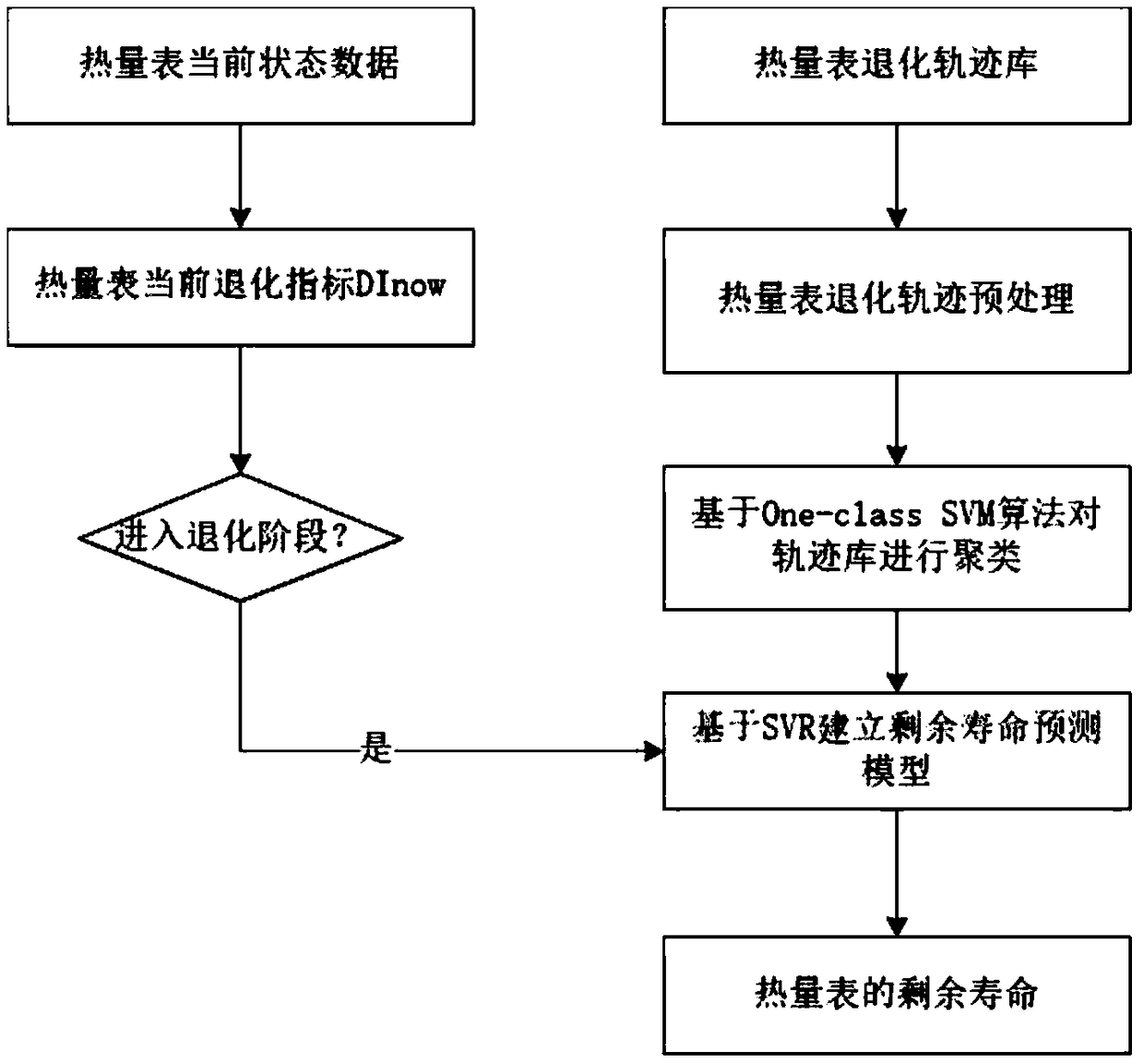

Method used

Image

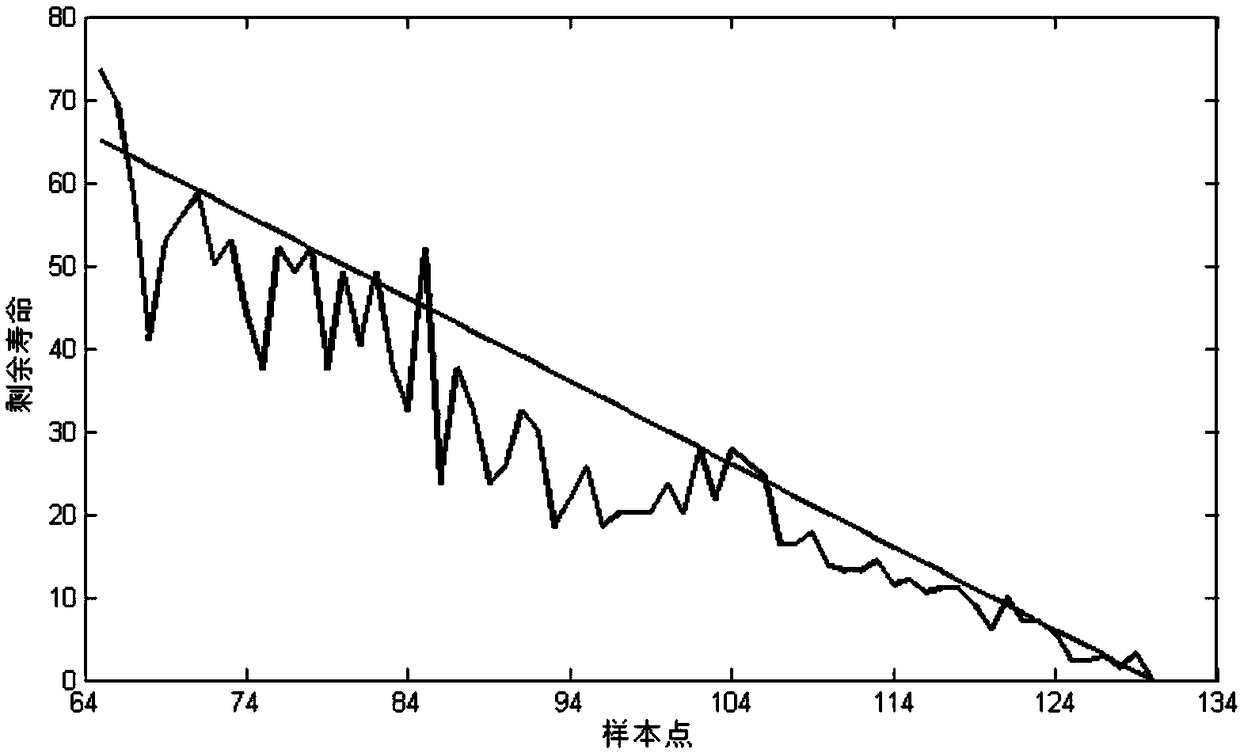

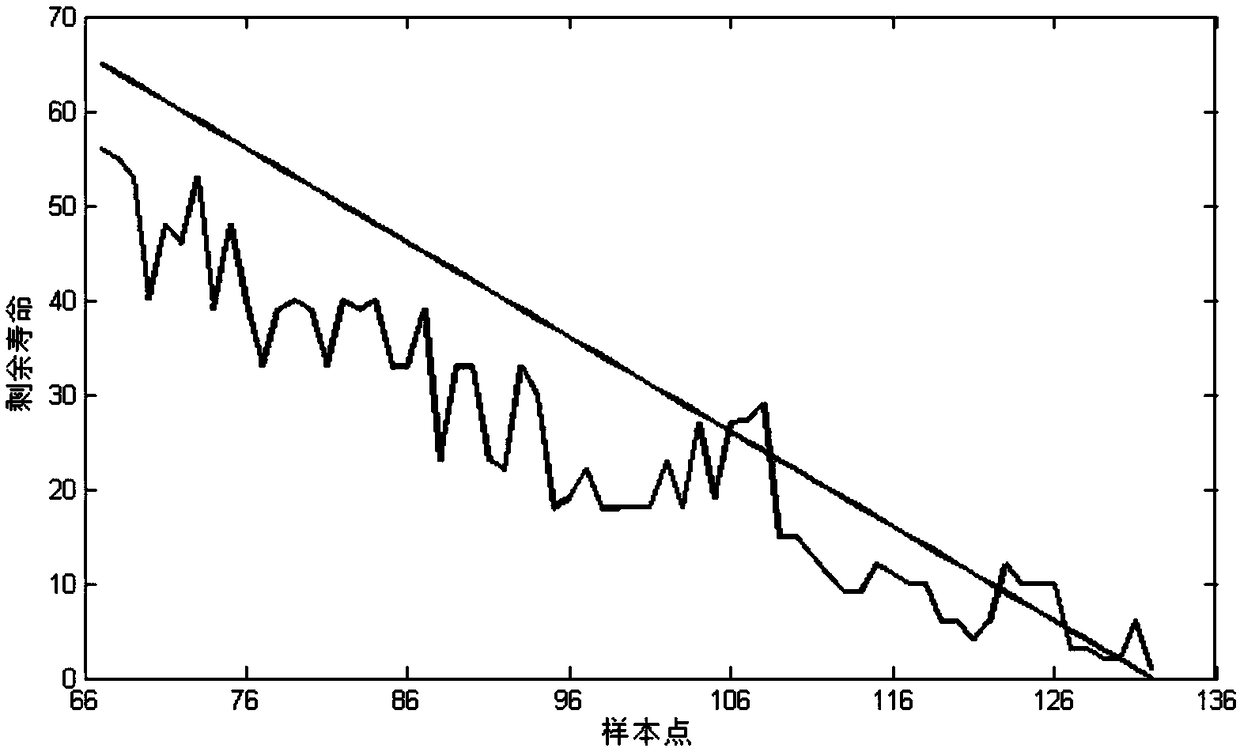

Examples

Embodiment Construction

[0051] Degradation Index (DI) is a reference established for studying equipment performance degradation to quantitatively describe the degree of performance degradation, and is widely used in the fields of equipment performance degradation and remaining life prediction.

[0052] Support Vector Machine (SVM) is a powerful tool developed under the statistical learning theory system to realize the principle of structural risk minimization. It mainly realizes the principle of structural risk minimization by keeping the empirical risk value fixed and minimizing the confidence range. It is suitable for Learn from small samples. SVM is mainly used in the field of pattern recognition (classification), while support vector regression (Support Vector Regression, SVR) is extended on the basis of SVM theory. As a regression algorithm with known results, it is obtained in the field of prediction. Wide range of applications.

[0053] One-class support vector machine (One-class SVM) is deve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com