Piezoelectric-Solenoid Double Valve Electronically Controlled Injector

An electronically controlled fuel injection and fuel injector technology, which is applied to fuel injection devices, machines/engines, charging systems, etc., can solve the problems of single working mode, poor working reliability, difficult to flexibly adjust the boost ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

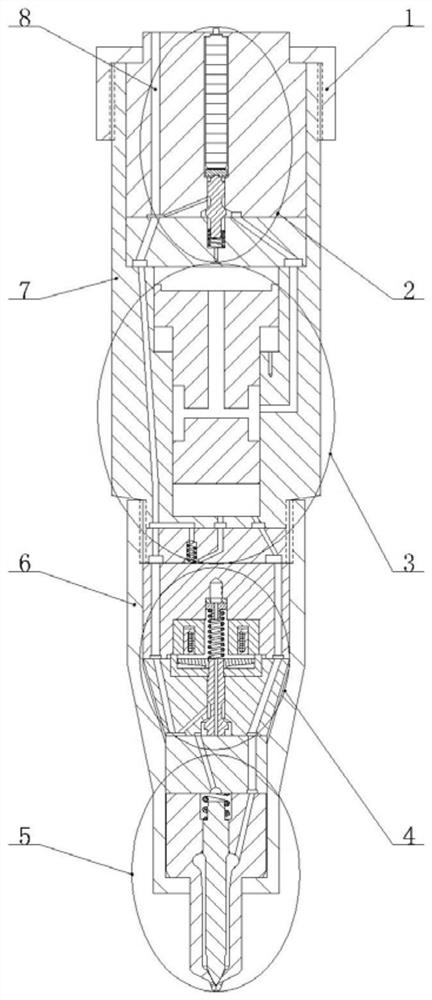

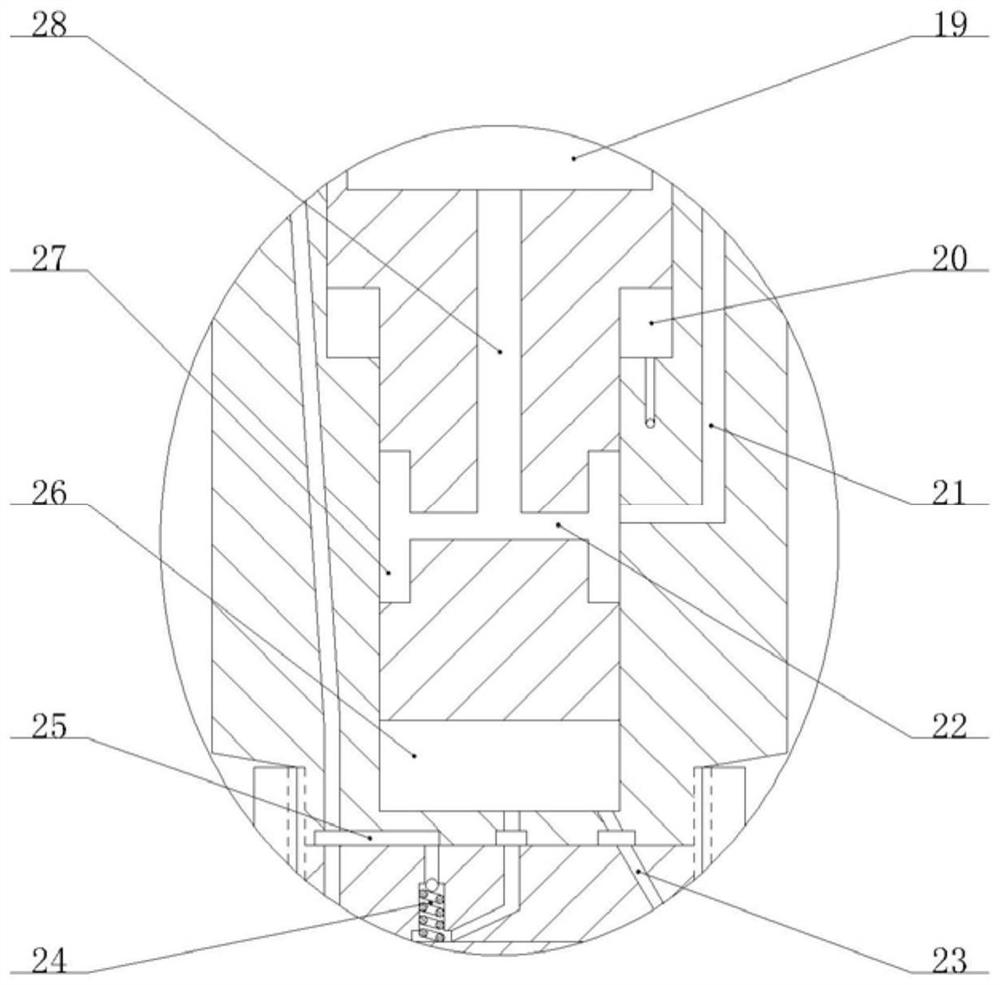

[0022] combine Figure 1-5 , the piezoelectric-electromagnetic dual-valve electronically controlled fuel injector of the present invention includes a fuel injector head 1, a boost control valve 2, a boost piston 3, a fuel injection control valve 4, a nozzle 5, a tight cap 6 and a fuel injector body 7, the injector head 1 is installed on the injector body 7, the booster control valve 2, the booster piston 3, the fuel injection control valve 4 and the nozzle 5 are installed in the injector body 7 sequentially from top to bottom, The tight cap 6 is fastened together with the fuel injector body 7 by threads.

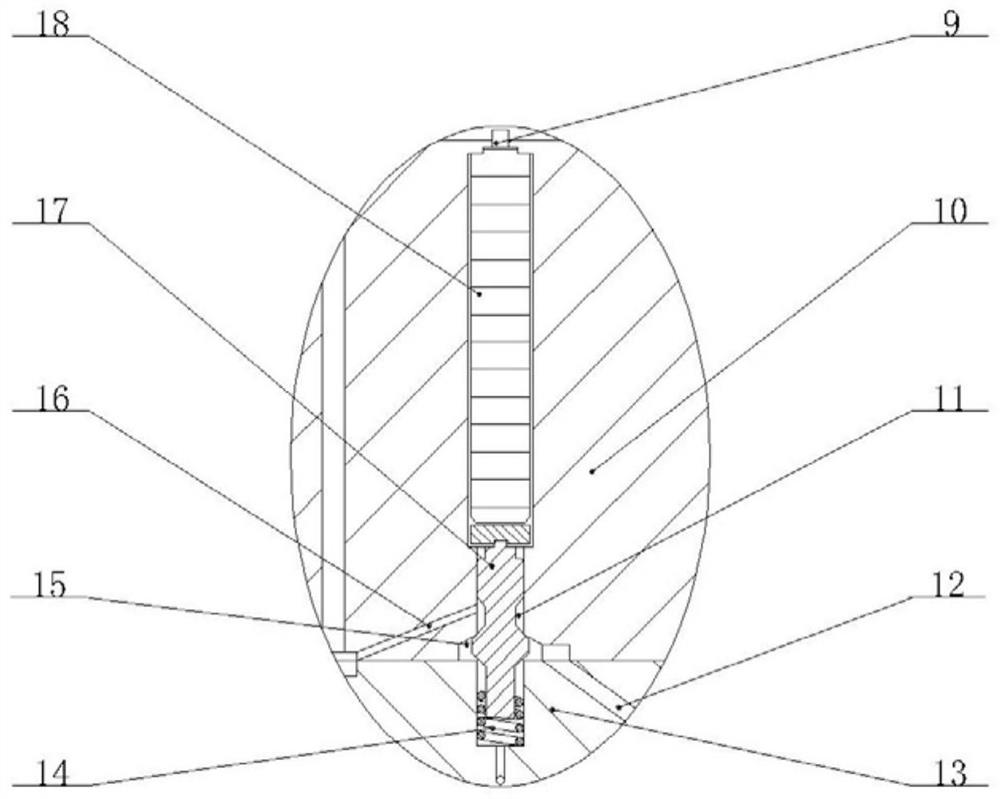

[0023] The boost control valve 2 is installed in the fuel injector body 7, and the boost control valve 2 includes an electrical connector 9, an upper valve seat 10 of the boost control valve, a lower valve seat 13 of the boost control valve, a reset spring 14 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com