Elevator steel wire rope head device and detecting method for steel wire rope tension

A technology of steel wire rope and rope head, applied in the elevator field, can solve the problems of inability to detect the tension force of the wire rope in real time, single spring vibration damping method, etc., and achieve the effect of ensuring safety, comfort and relativity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

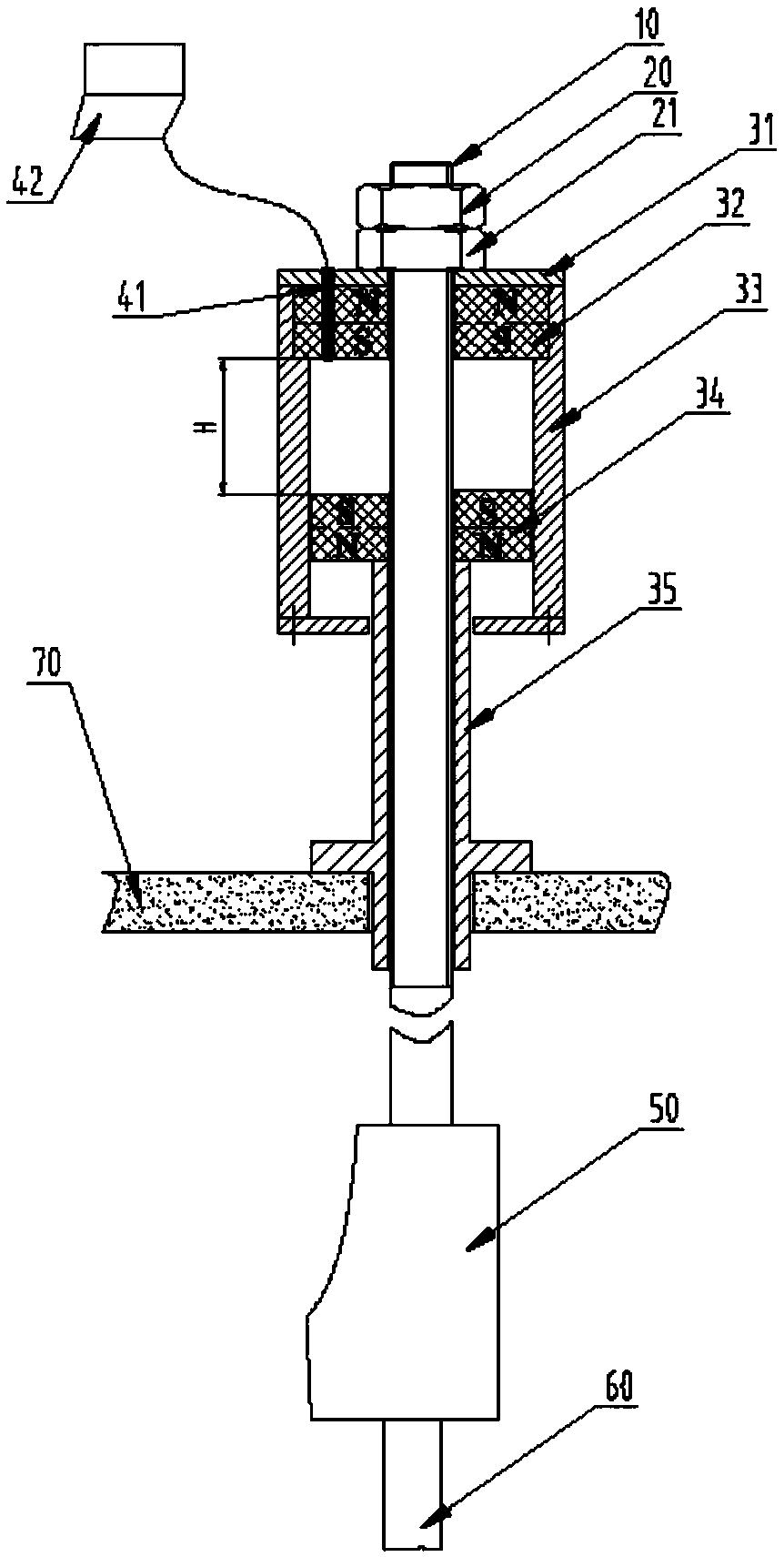

[0036] Such as figure 1 As shown, the static magnetic assembly includes a fixed base sleeve 35 and a lower magnet 34 , one end of the fixed base sleeve 35 is vertically fixed on the rope head plate 70 , and the lower magnet 34 is fixed on the other end of the fixed base sleeve 35 .

[0037] The movable magnetic assembly includes a pull rod 10 and an upper magnet 32, and one end of the pull rod 10 vertically passes through the lower magnet 34 and is enclosed within the sleeve, and is connected with one end of the rope end taper 50 at the same time, and the end of the rope end taper 50 The other end is connected with the wire rope 60 ; the upper magnet 32 is fixed on the other end of the pull rod 10 .

[0038] The position-limiting structure is a frame body fixed on the pull rod 10 and enclosing the upper magnet 32 and the lower magnet 34 inside. length.

[0039] Specifically, the frame body is a square, and the frame body includes a sleeve 33 and a backing plate 31, the b...

Embodiment 2

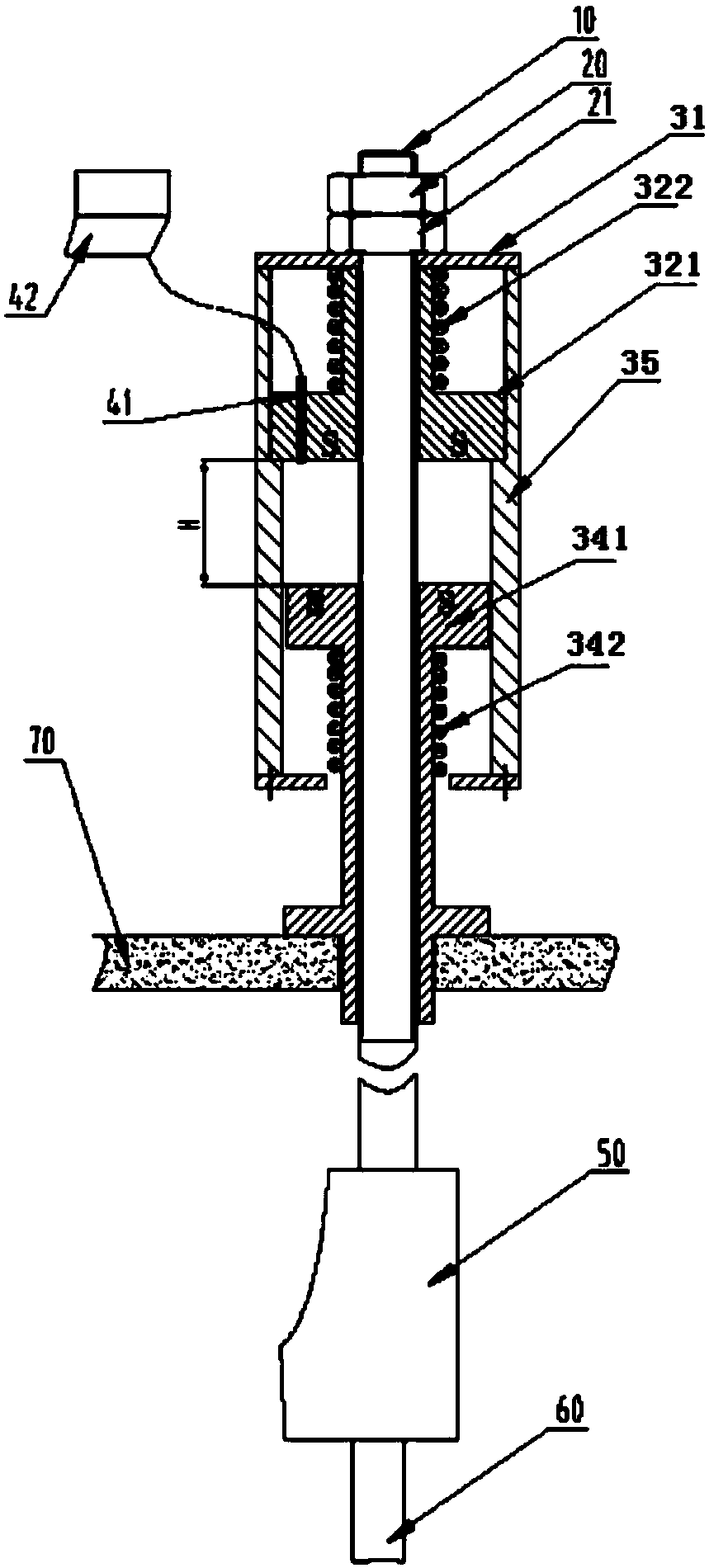

[0047] Such as figure 2 As shown, this embodiment discloses another elevator wire rope end device. In terms of structure, the difference between it and the elevator wire rope end device described in Embodiment 1 lies in the fact that the generation of the magnetic field is different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com