Method for pretreating printing substrates for inkjet printing

A technology for printing materials and inkjet printing, applied in printing, copying/marking methods, printing devices, etc., can solve the problems of reducing the quality of printed products, reduce the quality of printed images, etc., and achieve the effect of preventing streak formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

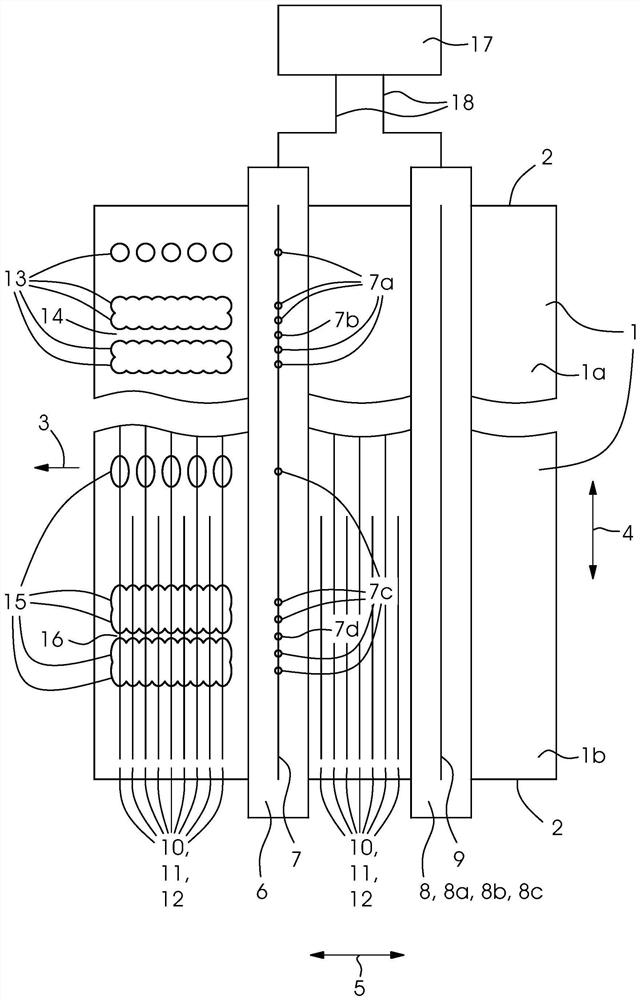

[0024] figure 1 A preferred embodiment of the method according to the invention is shown. figure 1 At the same time, a preferred embodiment of the device which is preferred for carrying out the method is also shown.

[0025] The printing material 1 (for example paper, cardboard or film) has side edges 2 . The printing material is conveyed along the device in a conveying direction 3 . The device can be part of an inkjet printing machine and can include at least one conveying element (in particular a conveying cylinder or a conveying belt) for the printing material. The transverse direction 4 runs perpendicular to the side edge 2 and the longitudinal direction 5 runs parallel to the side edge 2 .

[0026] A device suitable for carrying out the method according to the invention comprises an ink printing head 6 having an array of individually steerable nozzles 7 (extending substantially parallel to said transverse direction). The ink printing head 7 can be configured as an arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com