Hot melting apparatus

A hot-melt device and hot-melt technology, applied in the field of hot-melt, can solve problems such as no tight connection at the joint, affecting work efficiency, and broken joints, so as to prevent air bubbles and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

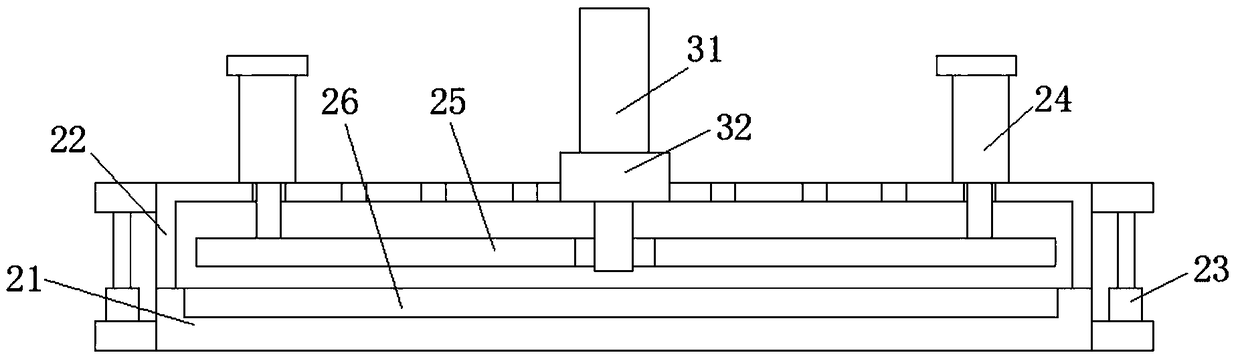

[0018] see Figure 1-2 , this embodiment provides a hot-melt device, including a frame 1, a hot-melt part 2 is fixedly installed on the top of the frame 1, and a feeding device 3 is arranged on the top of the hot-melt part 2, and the through-heating device 3 of the feeding device 3 The melting part 2 extends to the inside of the hot melting part 2. The top of the frame 1 is fixedly connected with the transfer table 4 located on both sides of the hot melting part 2. The top of the transfer table 4 is provided with a mounting groove 5, and the inner wall of the mounting groove 5 is rotatably connected with Transmission wheel6.

[0019] In this embodiment, the plates at both ends are connected by the hot-melt part 2, and the connected PVC plate is moved on the transfer platform 4 by the transmission wheel 6, so that it always moves in a horizontal state, avoiding the Turn up the PVC sheet to prevent the breakage of the connection, and set the transfer table 4 on both sides of th...

Embodiment 2

[0021] see Figure 1-2 , On the basis of Embodiment 1, a further improvement is made: the hot-melt part 2 includes a lower cold mold 21 and an upper cold mold 22, a hydraulic cylinder 23 is arranged between the lower cold mold 21 and the upper cold mold 22, and the upper cold mold 22 The top of the cylinder 24 is provided with a cylinder 24, the cylinder 24 runs through the upper cold mold 22 and extends to the inside of the upper cold mold 22, the bottom of the cylinder 24 is fixedly connected with an upper hot mold 25, and the top of the lower cold mold 21 is fixedly connected with a lower hot mold 26. When carrying out hot-melt operations, align the PVC sheets at both ends and place them on the lower hot mold 26, then retract the hydraulic cylinder 23, so that the upper cold mold 22 and the lower cold mold 21 fix the PVC sheet, and then the upper hot mold 25 and the lower hot mold The hot mold 26 runs and heats up. At this time, the cylinder 24 works and presses down the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com