An operating table for processing metal pipe fittings

A technology of operating table and work table, applied in the direction of work table, manufacturing tool, workpiece clamping device, etc., can solve the problems of single operating table structure, low processing quality, deviation of hardware pipe fittings, etc., to shorten the working stroke and disperse vibration. The effect of counteracting, increasing the strength of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

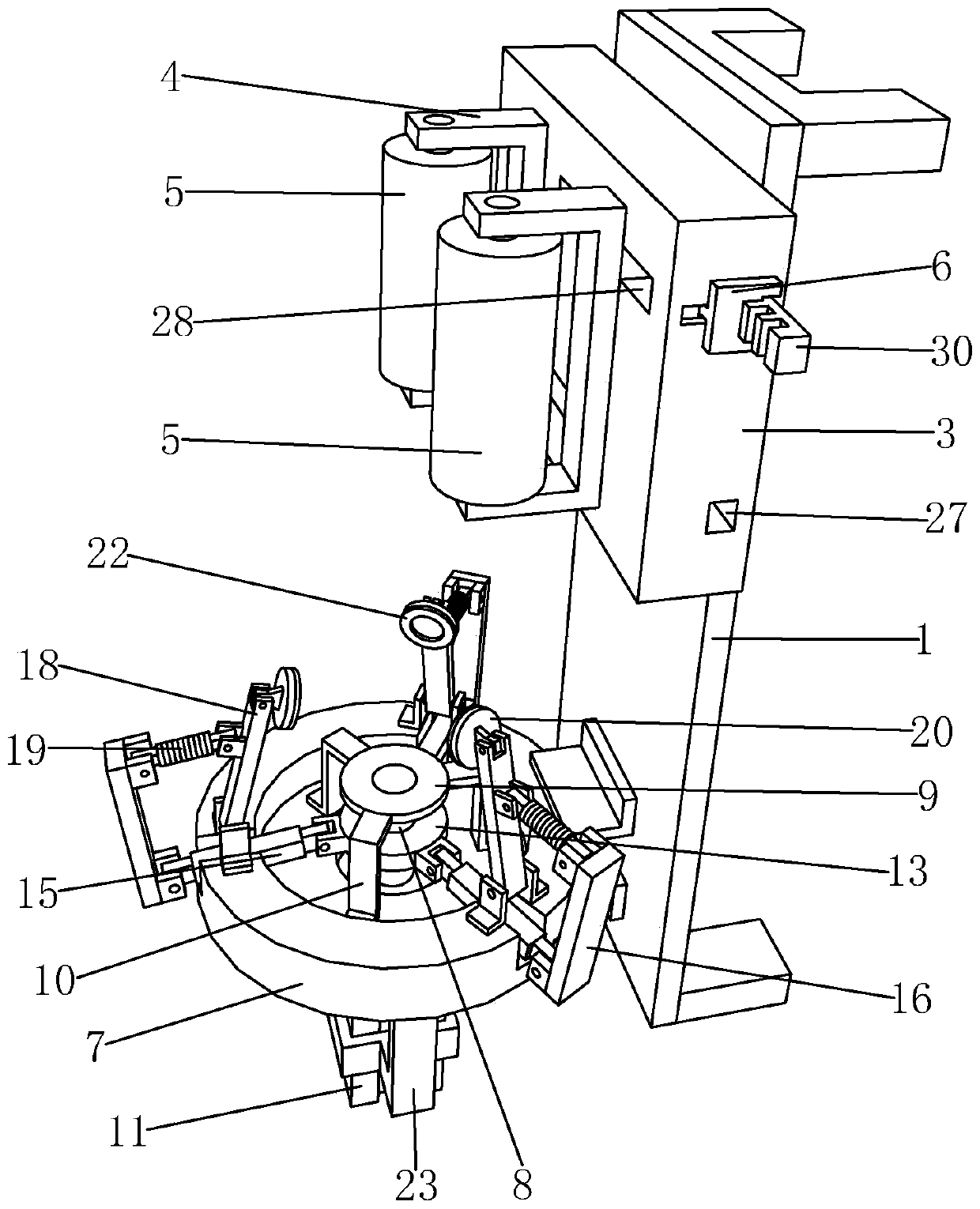

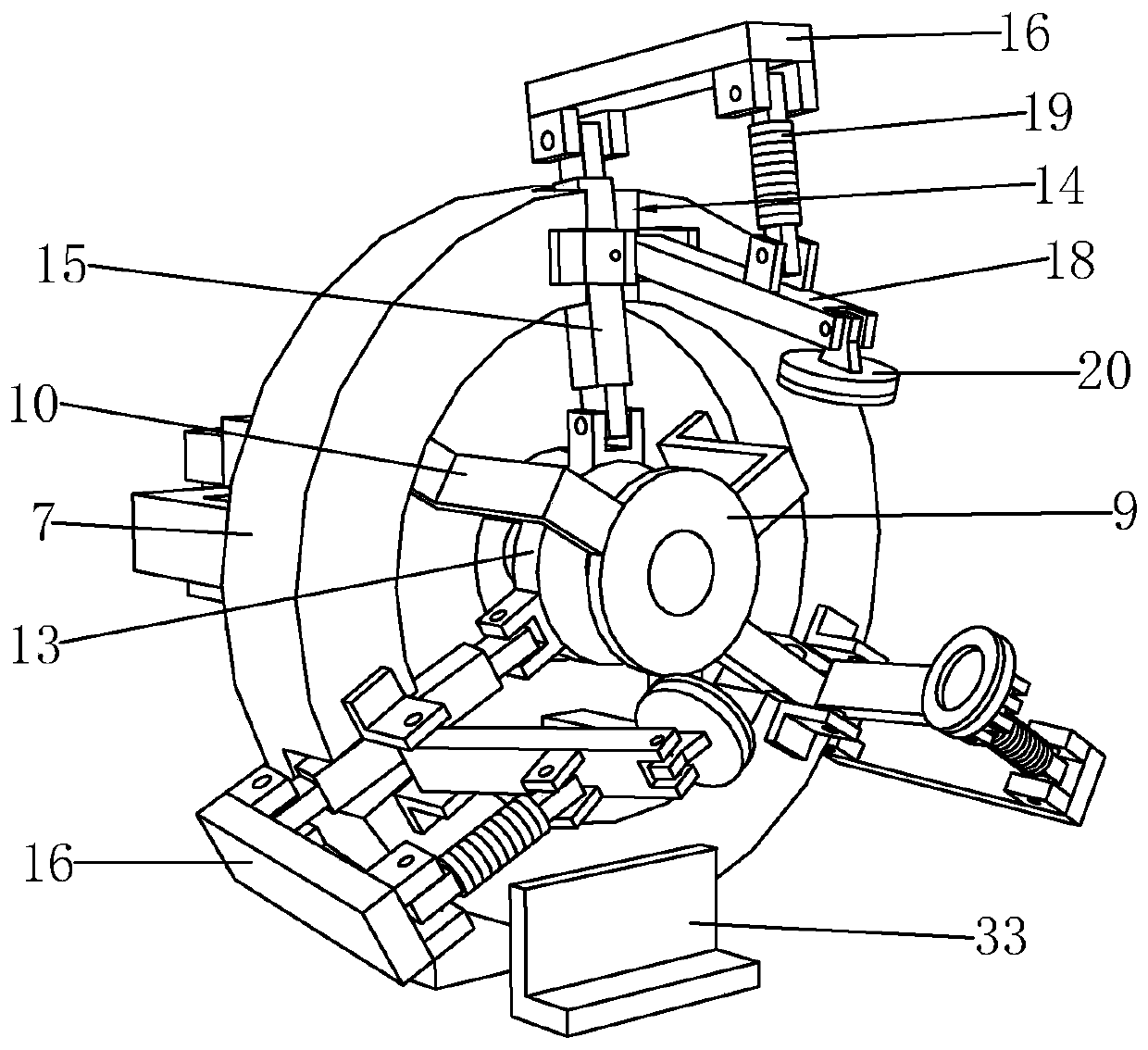

[0025] Such as Figure 1 to Figure 7 Shown is an operating table for processing hardware pipe fittings of the present invention. It includes a support frame 1, a workbench 3 is provided on the support frame 1, and a U-shaped seat 4 is slidably connected to the workbench 3, and the U-shaped seats 4 are symmetrically distributed. A positioning roller 5 is provided on the base 4, a positioning plate 6 is slidably connected to the side of the worktable 3, and the positioning plate 6 limits the movement of the U-shaped seat 4. The worktable 3 is provided with a fixed ring 7, and the center of the fixed ring 7 is provided Fixed shaft 8, one end of the fixed shaft 8 is provided with a mounting seat 9, the mounting seat 9 is surrounded by an L-shaped fixed rib 10, the L-shaped fixed rib 10 is provided on the fixed ring 7, the fixed shaft 8 is fixed by the L-shaped fixed rib 10 On the fixed ring 7, the firmness of the fixed shaft 8 installed on the fixed ring 7 is improved, the overall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com