Preparation method, use method and applications of magnetic carbon nano-tubes

A magnetic carbon nanotube and carbon nanotube technology, applied in the field of environment and chemistry, can solve the problems of difficult solid-liquid separation of carbon nanotube adsorbents, and achieve the effects of good magnetic separation performance, improved adsorption performance, and easy control of conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of magnetic carbon nanotube of the present invention comprises the following steps:

[0027] The first step: at room temperature, prepare a certain amount of aqueous solution containing manganese dichloride (0.125mol / L) and ferric chloride (0.25mol / L) in a conical flask to form a stable homogeneous system (wherein the molar ratio Mn:Fe=1:2).

[0028] Step 2: Weigh an appropriate amount of carbon nanotubes, add to the solution prepared in the first step, and stir evenly.

[0029] The carbon nanotubes used are single-wall, double-wall or multi-wall carbon nanotubes, and the carbon nanotubes are original samples of carbon nanotubes, which can be prepared by arc method or chemical vapor deposition or laser method original samples of carbon nanotubes. The quality of the carbon nanotubes used and the MnFe produced in the third step 2 o 4 The mass ratio is 1:1-1:5.

[0030] The third step: at a certain stirring speed, the temperature of the water ba...

Embodiment 1

[0036] Embodiment 1: Preparation of magnetic carbon nanotubes

[0037] A loaded MnFe 2 o 4 The preparation method of the carbon nanotube adsorbent of magnetic nanoparticles, the specific steps are as follows:

[0038] 1. Magnetic seed preparation: at room temperature, prepare 200ml of an aqueous solution containing manganese dichloride (0.025mol) and ferric chloride (0.05mol) in a 250ml Erlenmeyer flask to form a stable homogeneous system, denoted as solution A .

[0039] 2. Preparation of carbon nanotubes: Weigh 5.7735 g of multi-walled carbon nanotubes with a ten-thousandth balance, add them into solution A and stir evenly to obtain mixed solution B.

[0040] 3. Preparation of magnetic carbon nanotubes: under constant stirring, the temperature of the mixed liquid B in a water bath was raised to 60° C., and 3 mol / L sodium hydroxide solution was added dropwise to adjust the pH to 11, and the temperature was kept for 1 hour. Finally, keep warm in a 100°C water bath for 4 ho...

Embodiment 2

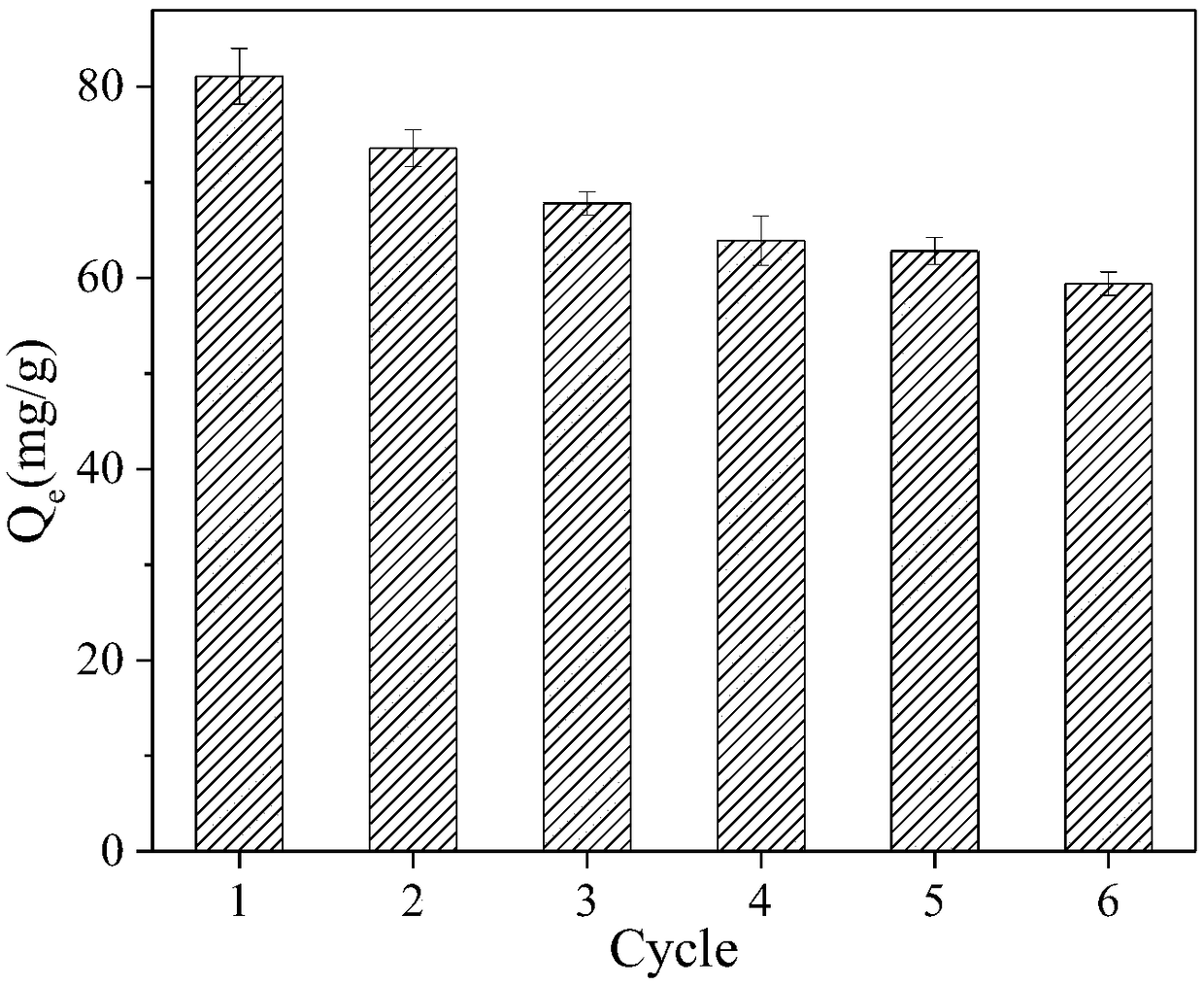

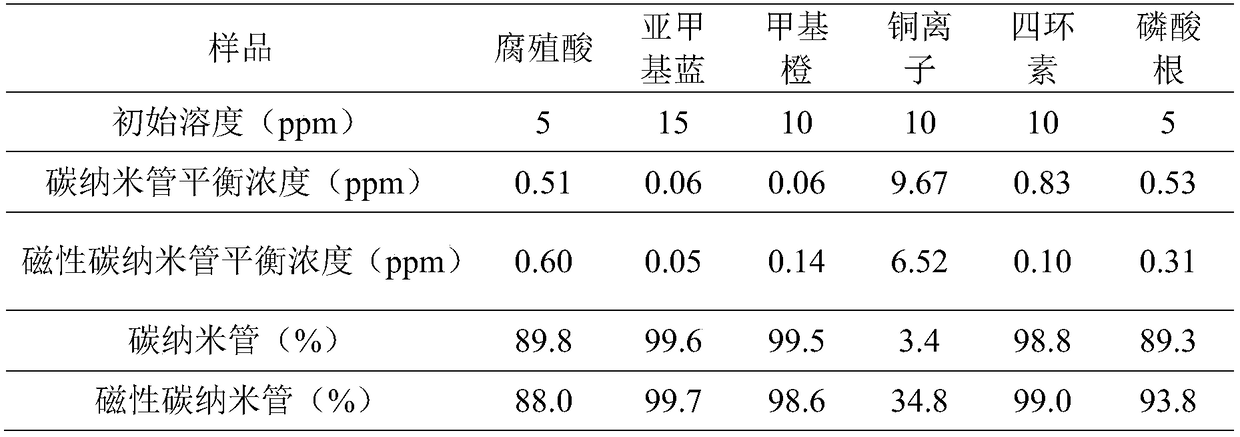

[0042] Example 2: Adsorption performance of magnetic carbon nanotubes

[0043]According to the magnetic carbon nanotubes prepared in Example 1, experiments on the adsorption and removal effects of humic acid, methylene blue, methyl orange, copper, tetracycline and phosphate ions in water were carried out. Take 10mg of magnetic carbon nanotubes and add them to 50ml of the above-mentioned pollutants, absorb in a shaker at 25°C and 140rpm for 24 hours, and then take samples. The samples are filtered through a 0.45um membrane and tested. The results are shown in Table 1:

[0044] Table 1

[0045]

[0046] It can be seen from Table 1 that the removal rates of magnetic carbon nanotubes to humic acid, methylene blue, methyl orange, copper ions, tetracycline and phosphate changed from the original 89.8%, 99.6%, 99.5%, 3.4%, 98.8% and 89.3 88.0%, 99.%, 98.6%, 34.8%, 99.0% and 93.8%, basically maintaining the same adsorption performance as carbon nanotubes; the adsorption and remova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com