Water net centrifugal purification device

A technology of centrifugal purification and water network, which is applied in the direction of combination device, separation method, and separation of dispersed particles, can solve the problems of unstable purification rate, difficult automatic cleaning and maintenance, etc., so as to improve exhaust efficiency, reduce maintenance cost, and apply wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

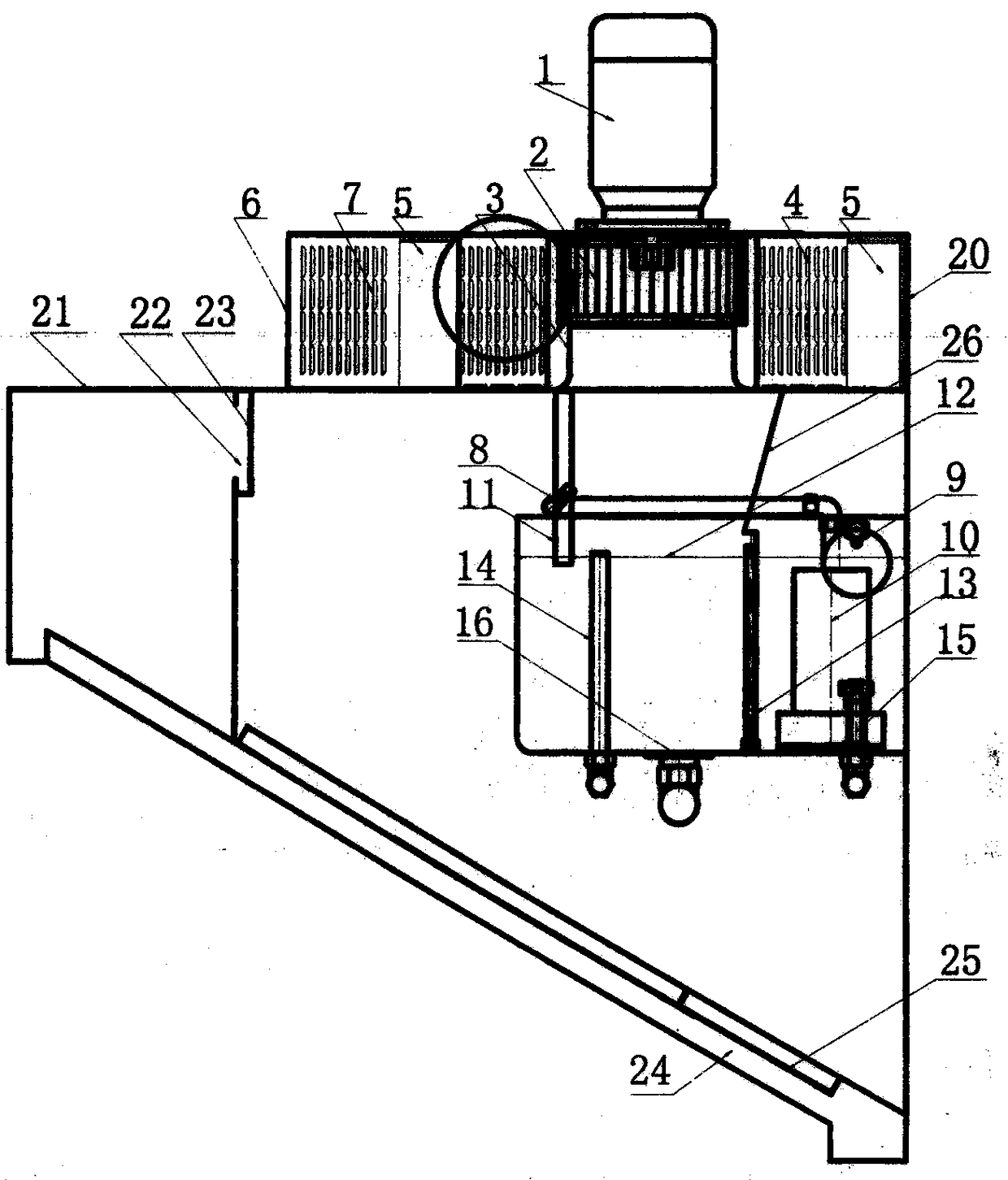

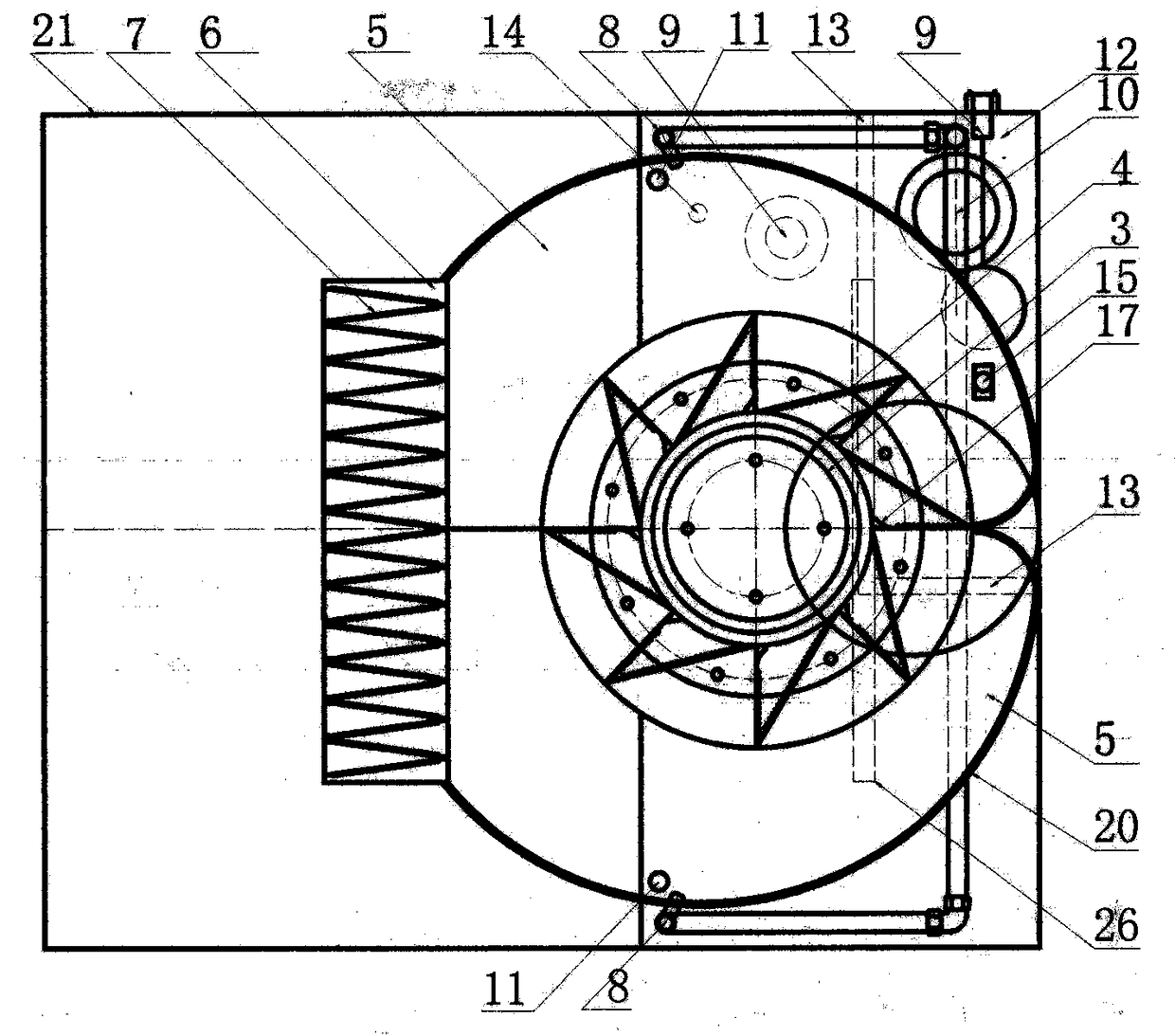

[0021] The present invention is further illustrated by means of examples shown in the accompanying drawings. figure 1 It is an application example of a purification exhaust hood made of a water network centrifugal purification device. exist figure 1 The top plate of shown exhaust hood (21) is fixedly installed water network centrifugal purification device, and motor (1) is installed on the top of water network centrifugal purification device, and air inlet (3) is communicated with in the exhaust hood, and circulating water tank water (12 ) is installed in the lower part of the water network centrifugal purification device in the smoke exhaust, and the return pipe (11) passes through the smoke exhaust hood top plate and stretches under the water surface of the circulating water tank. The water network centrifugal purification device is composed of a centrifugal wind wheel (2), a star-shaped fish-scale net folded plate (4), an atomizing nozzle (8) at an air inlet, and a sound-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com