Protein-free momordica grosvenori pure-flavor concentrated juice and production method thereof

A Luo Han Guo, protein-free technology, applied to the protein-free Luo Han Guo pure flavor concentrated juice and its production field, can solve the problems of high pigment content, high protein content, dark color, etc., and achieve a sweet taste, fragrant smell and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

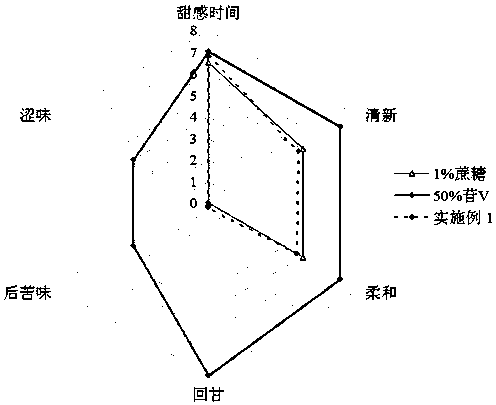

Embodiment 1

[0054] (1) Juicing and cold extraction of fresh fruit: After washing 100kg of Luo Han Guo fresh fruit, squeeze it with a juicer, then extract the pomace with 400kg of ice water at 10°C for 1 hour each time, and mix the juice with ice water The extracts are combined to obtain Luo Han Guo juice;

[0055] (2) Enzymolysis, boiling, and centrifugation: adjust the pH value of the Luo Han Guo fruit juice obtained in step (1) to 11 with a saturated aqueous solution of sodium hydroxide, then add 0.03kg of alkaline protease preparation, and enzymolyze at 15°C for 1 hour, Then, heat and boil the enzymolysis liquid at 95°C for 1 hour, rapidly cool it to 25°C at a speed of 1°C / min, and centrifuge to obtain the enzymolysis centrifugation liquid;

[0056] (3) Desalination and dealkalization: Put the enzymolysis centrifugate obtained in step (2) on the column with a flow rate of 2.0BV / h, and put it on a 001×16 type cation exchange resin column (the dosage of 001×16 type cation exchange resin ...

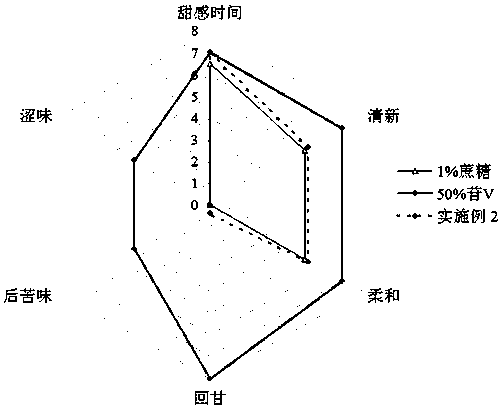

Embodiment 2

[0062] (1) Juicing and cold extraction of fresh fruit: After washing 200kg of Luo Han Guo fresh fruit, squeeze it with a juicer, and extract the pomace with 600kg of ice water at 8°C for 2 times, each time for 0.5h. The water extracts are combined to obtain Luo Han Guo juice;

[0063] (2) Enzymolysis, boiling, and centrifugation: adjust the pH value of Luo Han Guo fruit juice obtained in step (1) to 9 with a saturated aqueous solution of calcium hydroxide, then add 0.1kg of alkaline protease preparation, and enzymolyze at 25°C for 1.5h , and then, heat and boil the enzymolysis liquid at 90°C for 0.5h, rapidly cool it to 30°C at a speed of 2°C / min, and centrifuge to obtain the enzymolysis centrifugation liquid;

[0064] (3) Desalination and dealkalization: Put the enzymolysis centrifugate obtained in step (2) on the 001×7 type cation exchange resin column with the flow rate of the above column at 1.5BV / h (the dosage of 001×7 type cation exchange resin is 50kg , the height-to-d...

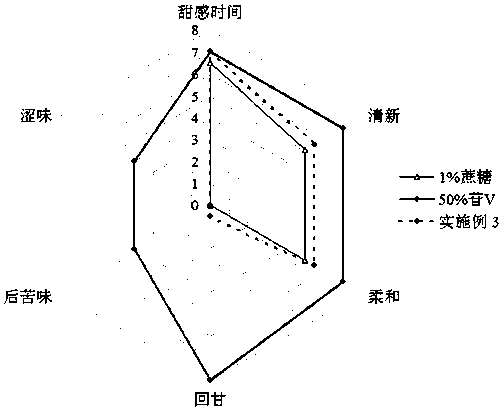

Embodiment 3

[0070] (1) Juicing and cold extraction of fresh fruit: After washing 200kg of Luo Han Guo fresh fruit, squeeze it with a juicer, then extract the pomace with 1000kg of ice water at 15°C for 1 hour each time, and mix the juice with ice water The extracts are combined to obtain Luo Han Guo juice;

[0071] (2) Enzymolysis, boiling, and centrifugation: adjust the pH value of Luo Han Guo fruit juice obtained in step (1) to 10 with a saturated aqueous solution of potassium hydroxide, then add 0.08kg of alkaline protease preparation, and enzymolyze at 20°C for 2 hours, Then, heat and boil the enzymolysis liquid at 100°C for 1 hour, rapidly cool it to 25°C at a speed of 1.5°C / min, and centrifuge to obtain the enzymolysis centrifugation liquid;

[0072](3) Desalination and dealkalization: Put the enzymolysis centrifugate obtained in step (2) on the 001×8 type cation exchange resin column with the flow rate of the above column at 1.0BV / h (the dosage of 001×8 type cation exchange resin i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com