A rear-mounted electric spindle structure with braking function

A brake function and tail-mounted technology, which is applied in the field of tail-mounted electric spindle structure, can solve the problems of large space occupation, complex mechanical structure, and large heat generation, and achieve the effects of preventing signal interference, good control effect, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

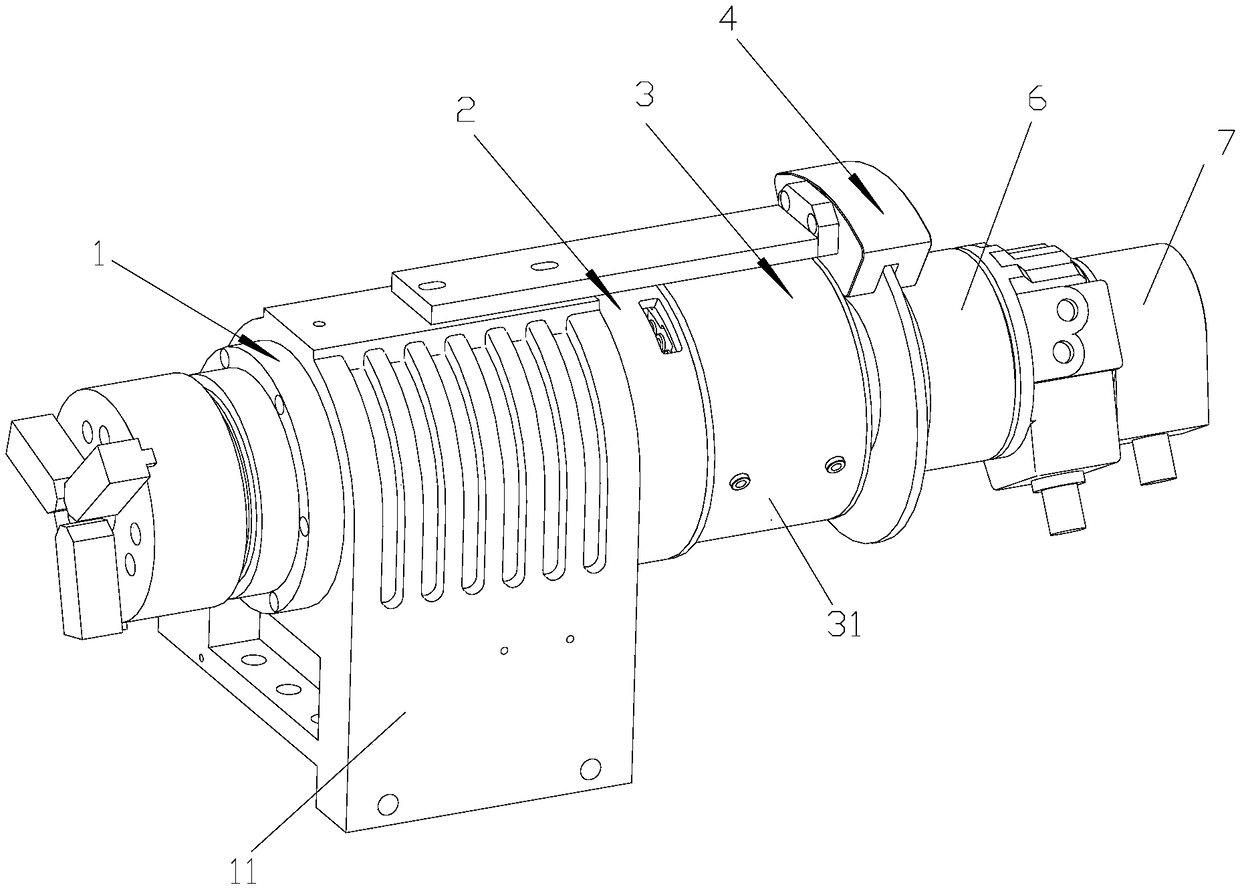

[0024] Such as Figure 1-6 As shown, a tail-mounted electric spindle structure with a braking function includes a mechanical spindle assembly 1, a flange 2, and a rear-mounted motor 3; the mechanical spindle assembly 1 is fixedly connected to the rear-mounted motor 3 through the flange 2, It also includes a braking device 4; an encoder mounting position 23 is provided in the flange 2; a slot 231 for hiding the encoder 5 wiring is provided on the encoder mounting position 23; An encoder 5 is installed; the braking device 4 has the functions of releasing, semi-braking and braking the main shaft 12 on the mechanical main shaft assembly 1 .

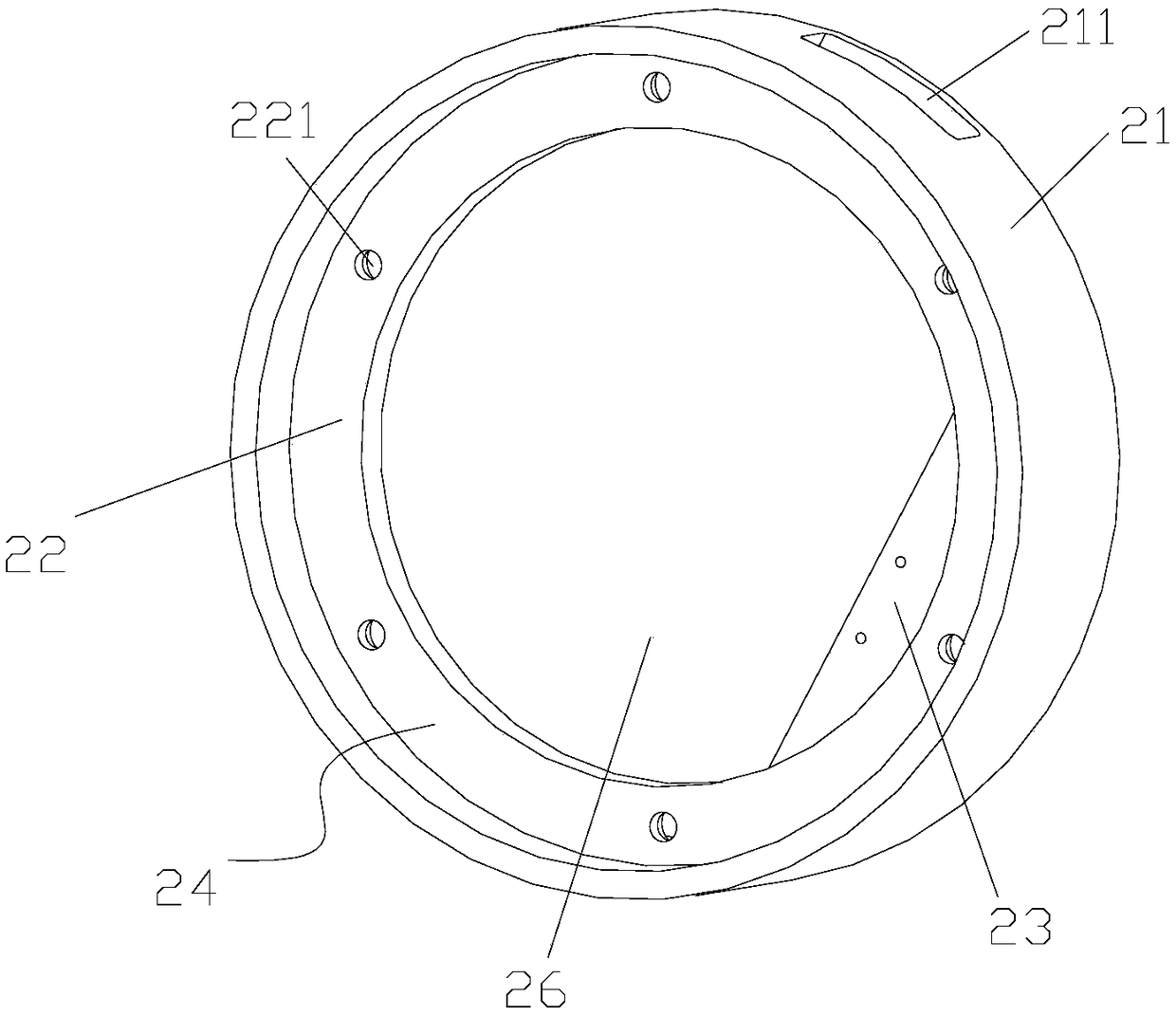

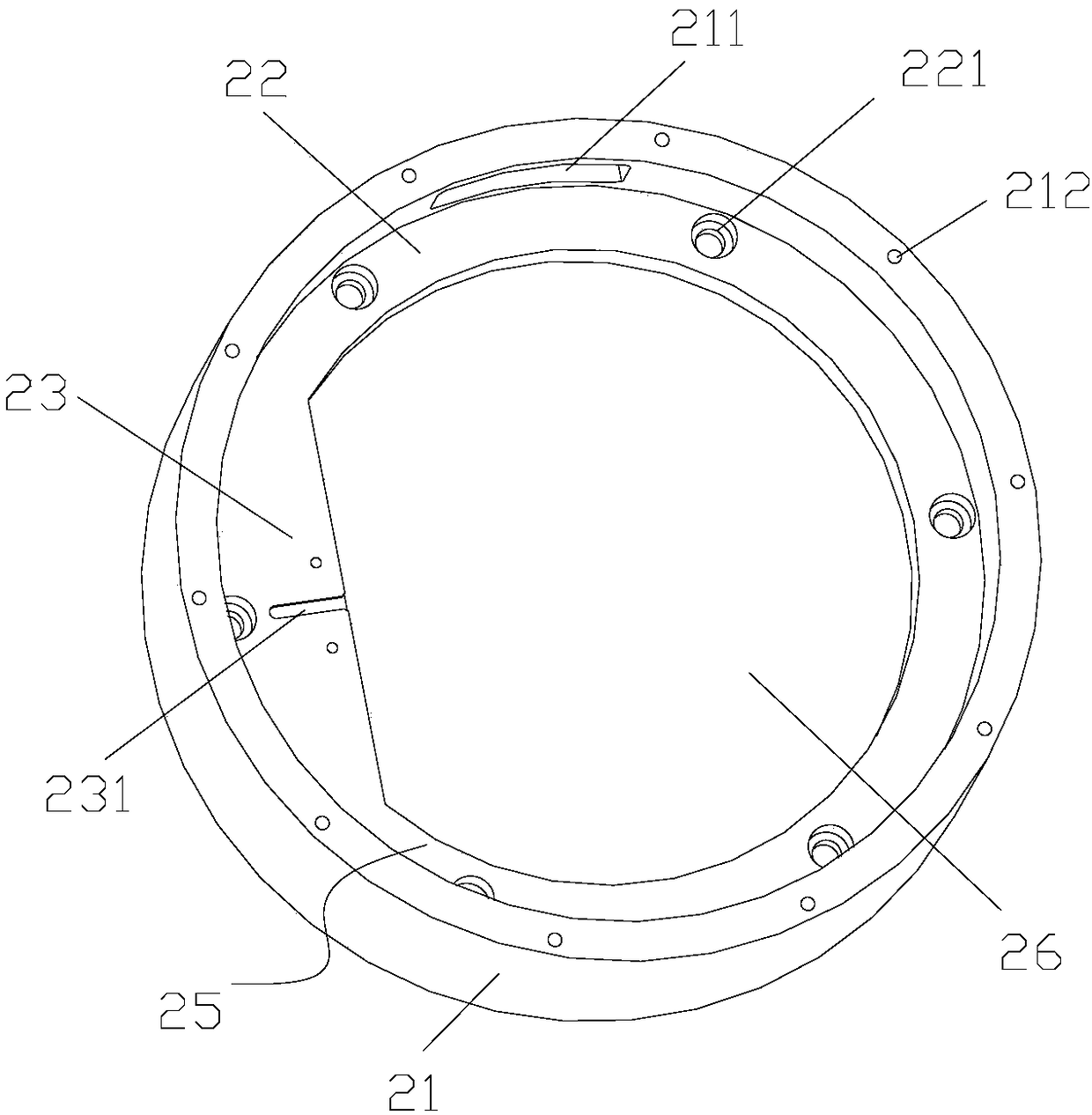

[0025] The flange plate 2 includes a circular flange housing 21 and a protruding ring 22 arranged inside the flange housing 21; the mounting position is arranged on the protruding ring 22 to form a "D"-shaped through hole with the protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com