A Scheduling Method to Solve WBS Sorting Problem

A scheduling method and a technique for sorting problems, applied in the direction of program control, electrical program control, control/regulation system, etc., can solve problems such as complex constraints, delivery delays, and retention, so as to avoid frequent replacement and delivery Delay, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples of implementation.

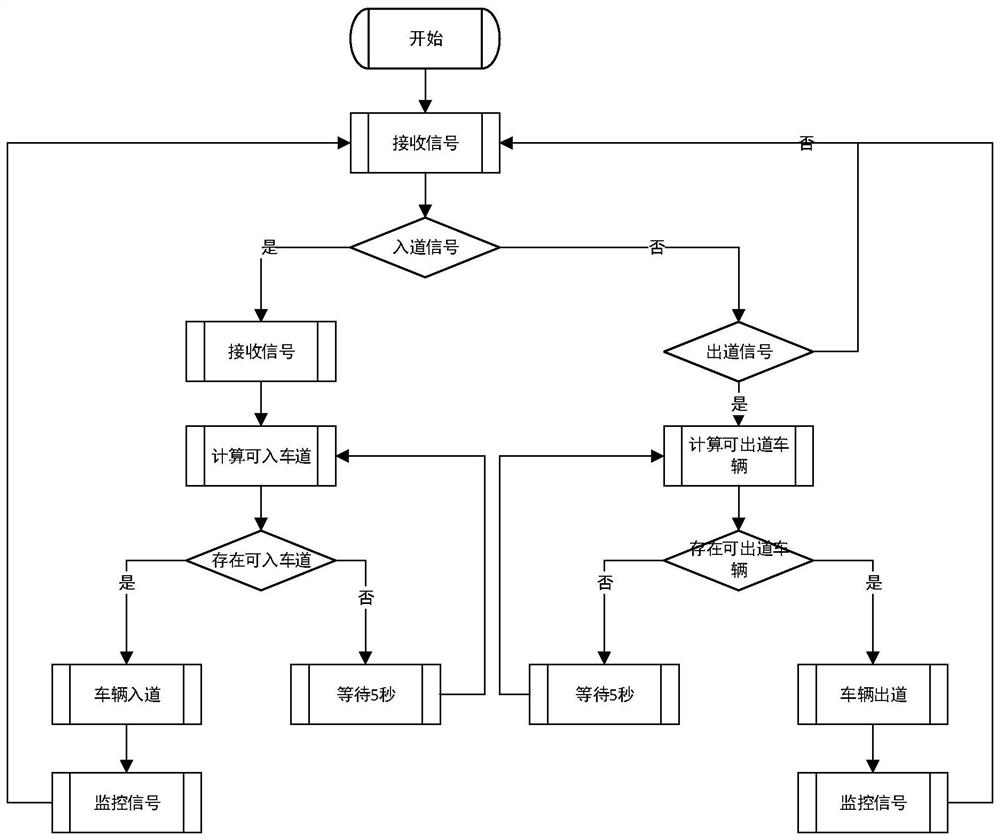

[0040] Such as figure 1 shown. A scheduling method for solving the WBS sorting problem, comprising the following steps:

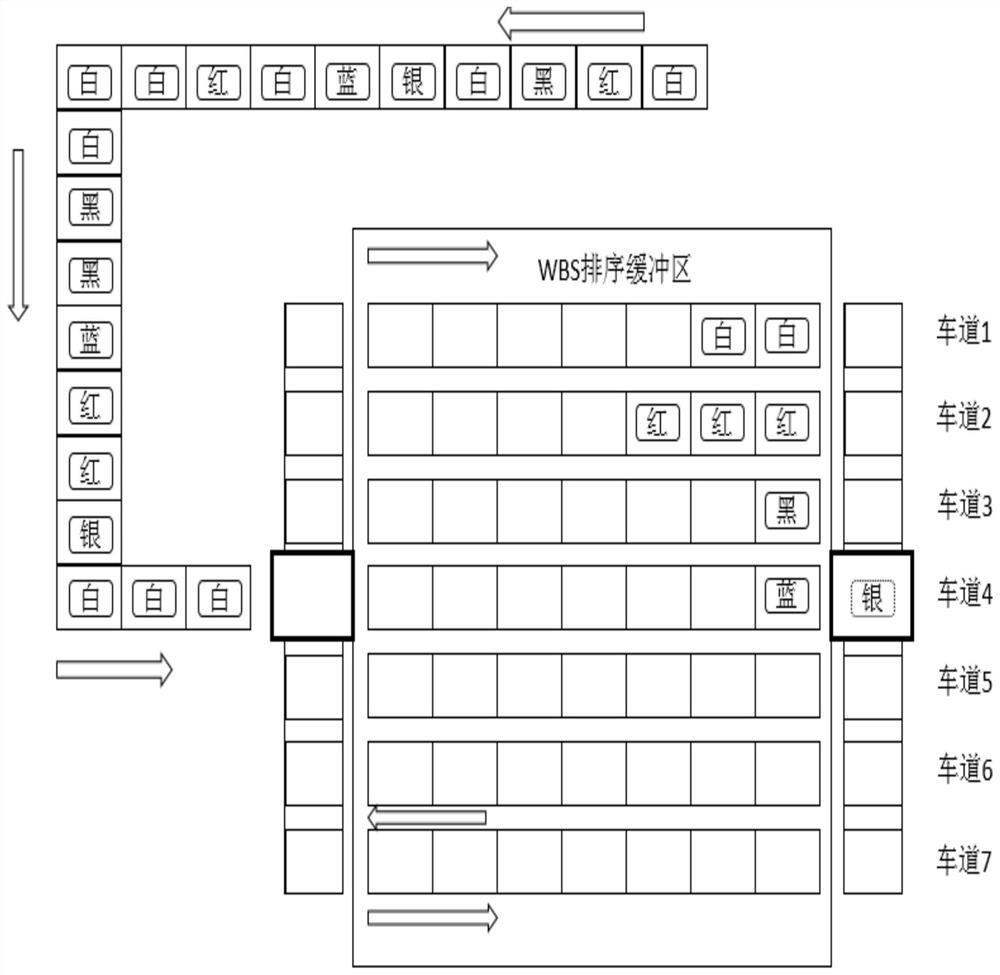

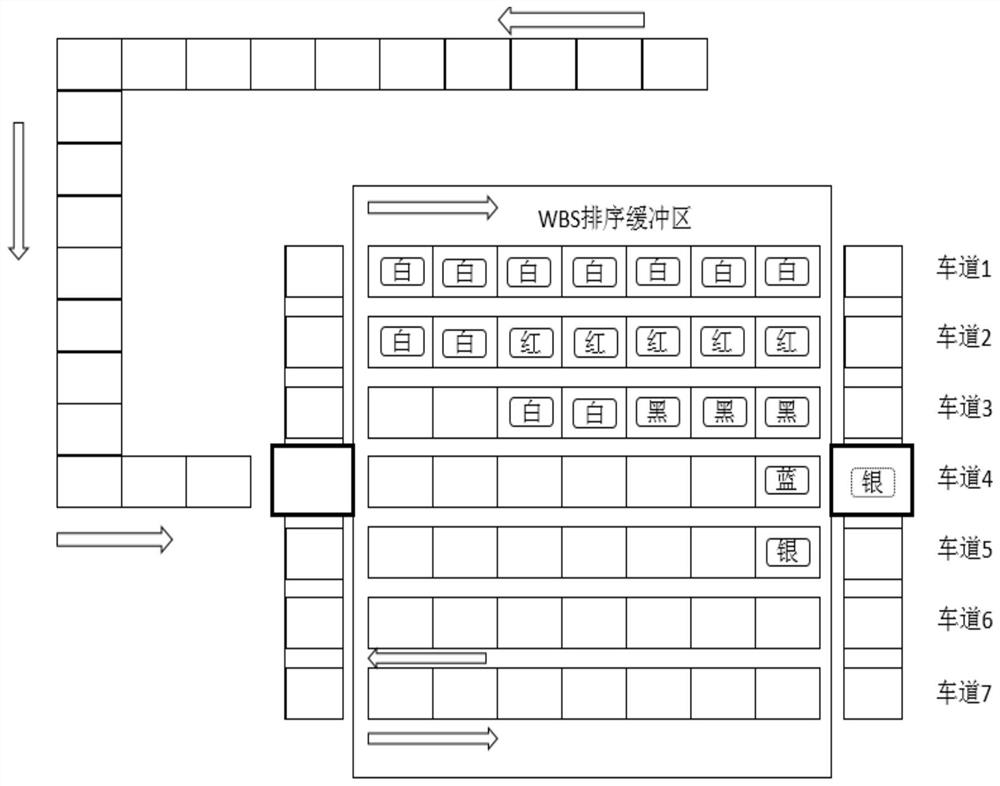

[0041] Step 1: Abstract the logic of WBS buffer W into a collection of FIFO (First In First Out) queues, expressed as n is the number of WBS buffer queues; where P i It is a FIFO queue, and the FIFO queue is divided into the following types: fast FIFO queue, common FIFO queue, return FIFO queue, specific queue, and frozen queue;

[0042] Step 2: Define Vehicle C i property, vehicle C i The attributes of include vehicle unique identifier, vehicle type, vehicle color, model, engine type, gearbox type, and off-line time; among them, the vehicle type identifies the vehicle as a special vehicle or an ordinary vehicle. Special cars or ordinary cars are set according to demand.

[0043] Step 3: Define the FI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com