Image forming method, image forming apparatus, and toner image fixing apparatus

A toner image and toner technology, applied in the field of toner image fixing devices, can solve the problems of reduced color reproducibility, lack of fixability, etc., and achieve the effect of good color reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

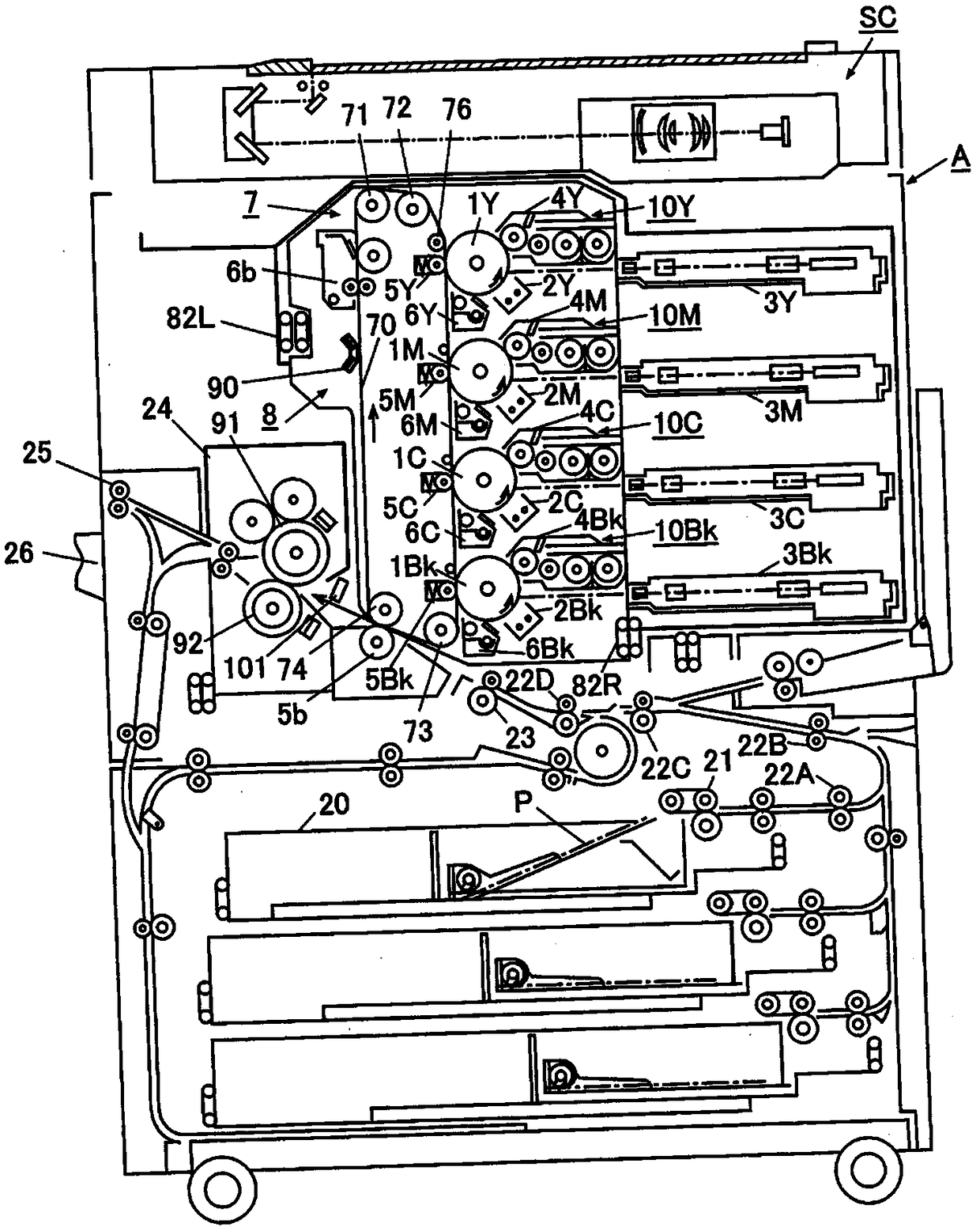

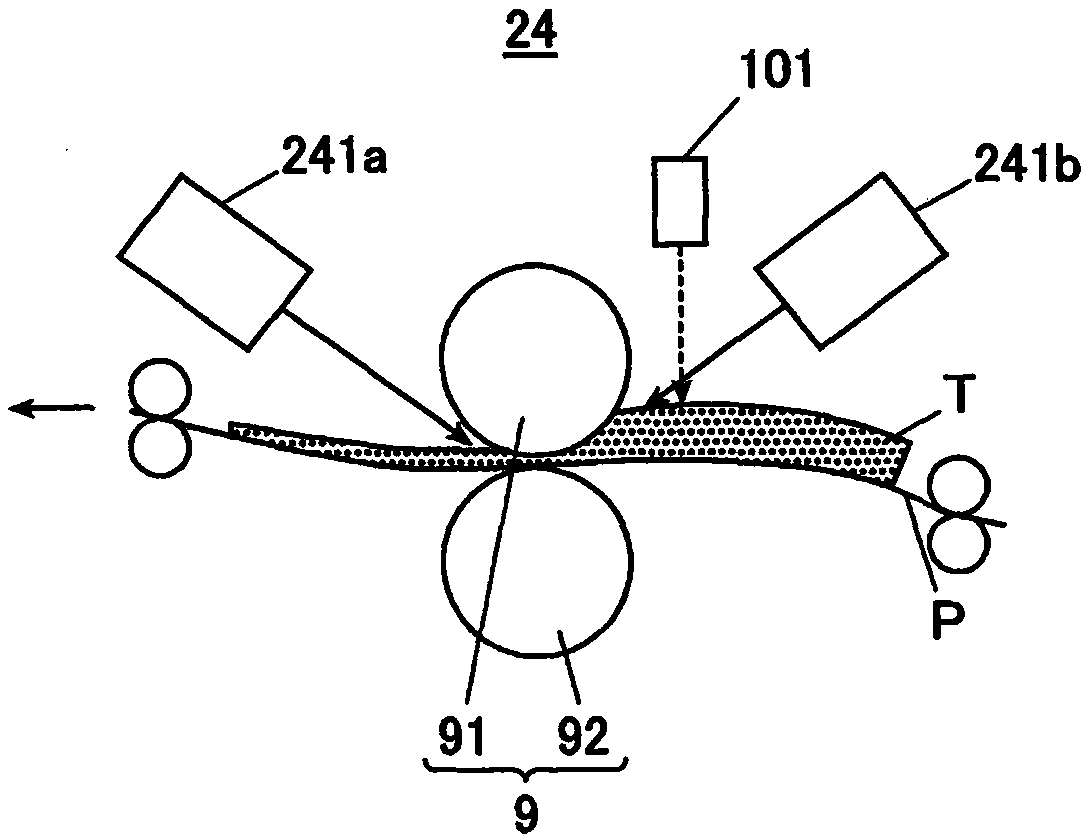

Method used

Image

Examples

Embodiment 10~12

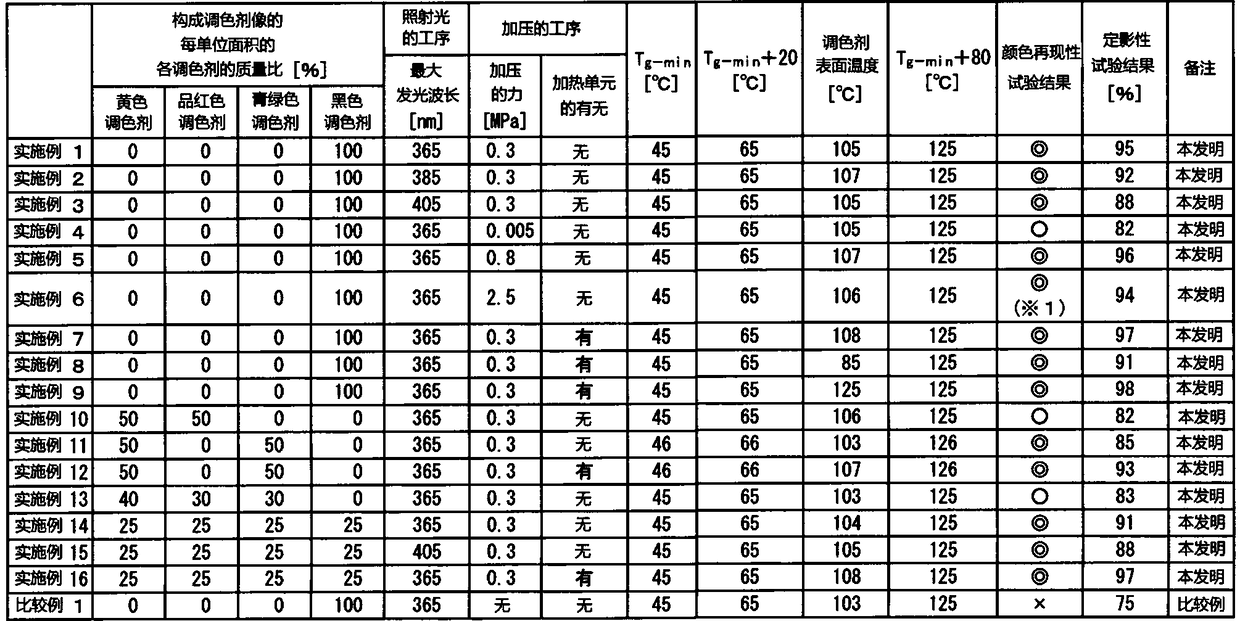

[0235] In order to fix the obtained solid patch image and each solid patch fixed image obtained by fixing the toner surface temperature ( 241 b ) to 125° C. by heating and pressing without irradiating light to each toner structure For comparison, the color of the solid portion in each image was measured with a fluorescence spectrodensitometer “FD-7” (manufactured by Konica Minolta Co., Ltd.), and the color difference was calculated using the CMC (2:1) color difference formula. Evaluation was performed according to the following criteria, and there was no practical problem if it was ◯ or more.

[0236] (evaluation criteria)

[0237] : color difference is less than 2

[0238] ○: Color difference is 2 or more and less than 3.5

[0239] ×: Color difference is 3.5 or more

[0240]

[0241] On plain paper (basis weight: 64g / m 2 ), the toner adhesion amount is 4g / m 2 conditions to develop the electrostatic latent image. This is performed using a printed matter in which a so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com