Shearing clamp and method for measuring material shearing performance and deformation using same

A measurement method and technology of deformation, applied in the direction of using stable shear force to test the strength of materials, analyzing materials, measuring devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

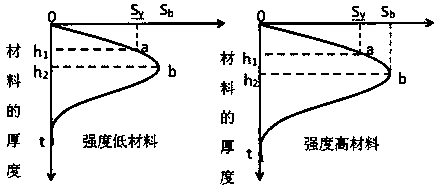

Problems solved by technology

Method used

Image

Examples

Embodiment 1

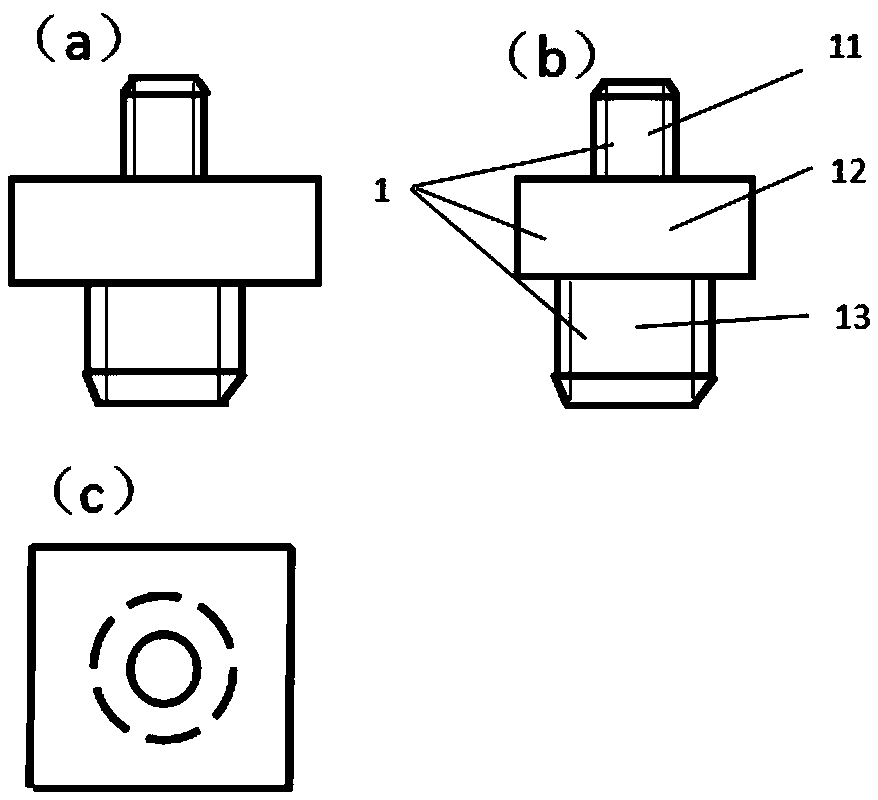

[0123] A kind of shear fixture, it is made of 2 parts: outer fixture 9 and inner fixture 3; Wherein: outer fixture 9 is mainly made of base part 1 (such as figure 1 shown) and function 2 (as figure 2 As shown), the overall shape of the functional part 2 is a cuboid structure, and a square through hole 23 is arranged on it along the length direction of the cuboid structure, and the size of the square through hole 23 is matched with the inner fixture 3; so that it can accommodate the inner clamp 3 deep into the square through hole 23;

[0124] The functional part 2 is provided with 4 sides parallel to the length direction, wherein: 2 sides arranged parallel to each other are provided with a through groove 21 passing through the two sides, and the through groove extends to the aforementioned 2 parallel sides. The lower end face of the functional part 2 whose sides are vertical at the same time, and the lower end face of the functional part 2 is divided into two relatively indep...

Embodiment 2

[0157] A kind of shear fixture and its material shear performance and deformation measurement method, through the above described shear sample fixture (suitable for various shapes of sample samples and can be stretched and compressed to realize shearing) to TC11 titanium Alloys were tested for shear properties.

[0158] TC11 titanium alloy is a typical α+β type duplex titanium alloy (nominal composition: Ti-6.5Al-3.5Mo-1.5Zr-0.3Si(wt.%)), which has good comprehensive mechanical properties and is a Important aviation and aerospace materials are widely used in parts such as blades of aero-engines, compressor discs, and some structural parts of aircraft.

[0159] The single and double shearing devices are made of T10 steel (hardness 60HRC), and the fastening bolts are 10.9 high-strength bolts, and the bolt material is 20MnTiB. Figure 1-3 Carry out shearing device processing, wherein the width of the square slot hole of the inner fixture is W=10mm, the thickness B=8mm, the upper...

Embodiment 3

[0180] The content of this embodiment is basically the same as that of embodiment 2, the difference being that: according to the shear test process described in embodiment 1, the shearing device is used to carry out the double shear of part shear deformation control to TC4 titanium alloy. test.

[0181] The composition of titanium alloy TC4 material is Ti-6Al-4V, which belongs to (α+β) type titanium alloy and has good comprehensive mechanical and mechanical properties. Same as embodiment 1, wherein the width W=10mm of the square slot hole of the inner fixture, the thickness B=8mm, the upper bottom surface of the right-angled trapezoidal hole of the outer fixture is W×B, the lower bottom surface is W×(B+1), and the circular hole The diameter D = 6mm.

[0182] Then adopt the same shear process as in Example 1, and the difference from the shear test of the TC11 titanium alloy is that a series of shear deformation tests are performed on the TC4 titanium alloy this time, 10%, 20%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com