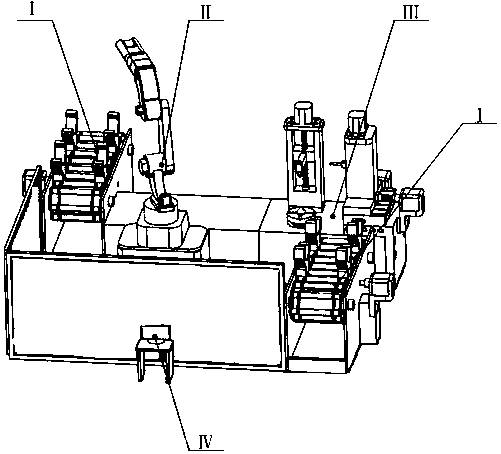

Automatic detection device of tooth face precision of gear shaft

An automatic detection device and technology of detection device, applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as hidden safety hazards of installation accuracy, manual loading and unloading, and inaccurate detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

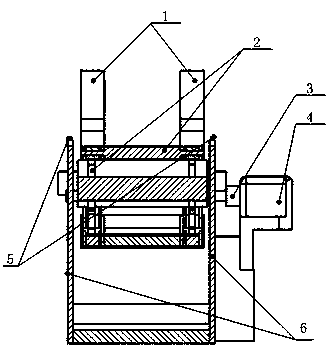

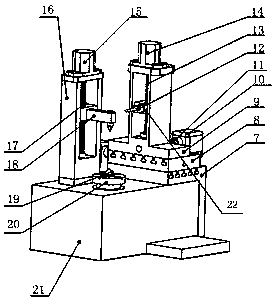

[0013]Place the gear shaft to be tested in the detection storage area, and consign the gear shaft from the detection storage area through the automatic transport device Ⅰ, where the motor (4) drives the gear in the sprocket (2) to rotate through the coupling (3) and then Make the chain of the sprocket (2) move, and the gear shaft consignment claw (1) installed on the chain consigns the gear shaft to the top of the positioning sensor (5) installed on the table body (6); the manipulator II passes through the big arm ( 48) Drive the middle arm (47) to move, then the small arm (46) drives the mechanical claw (44) on the basis of the movement of the middle arm (47) to pick up the gear shaft on the consignment claw (1), and through the rotating arm (45) Turn the gear shaft to a certain angle to ensure that the gear shaft reaches a vertical position, and install the gear shaft on the detection device III, and fix it by the lower center and the upper center (18) installed in the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com