Self-adaption intake muffler

An air intake muffler, adaptive technology, applied in the direction of intake muffler, machine/engine, combustion air/combustion-air treatment, etc., can solve the problem of a single effective frequency range, inability to adapt to different medium noise frequencies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

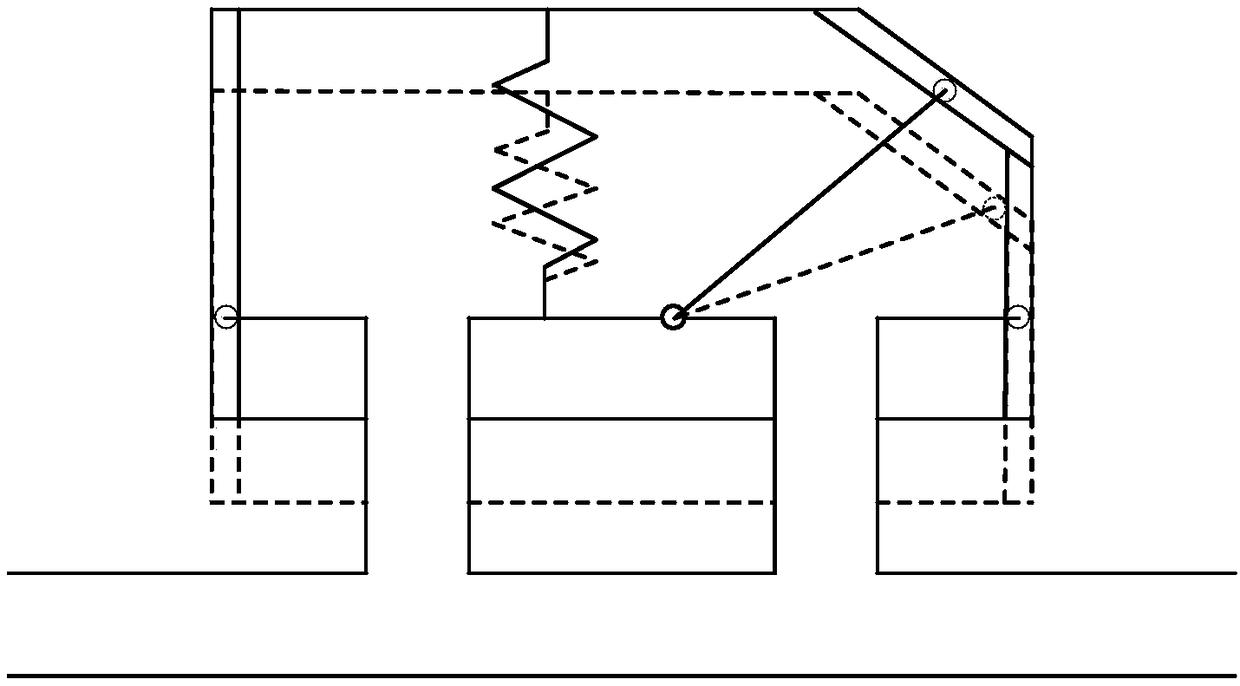

[0019] The following combination image 3 , to describe the preferred embodiments of the present invention in detail; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

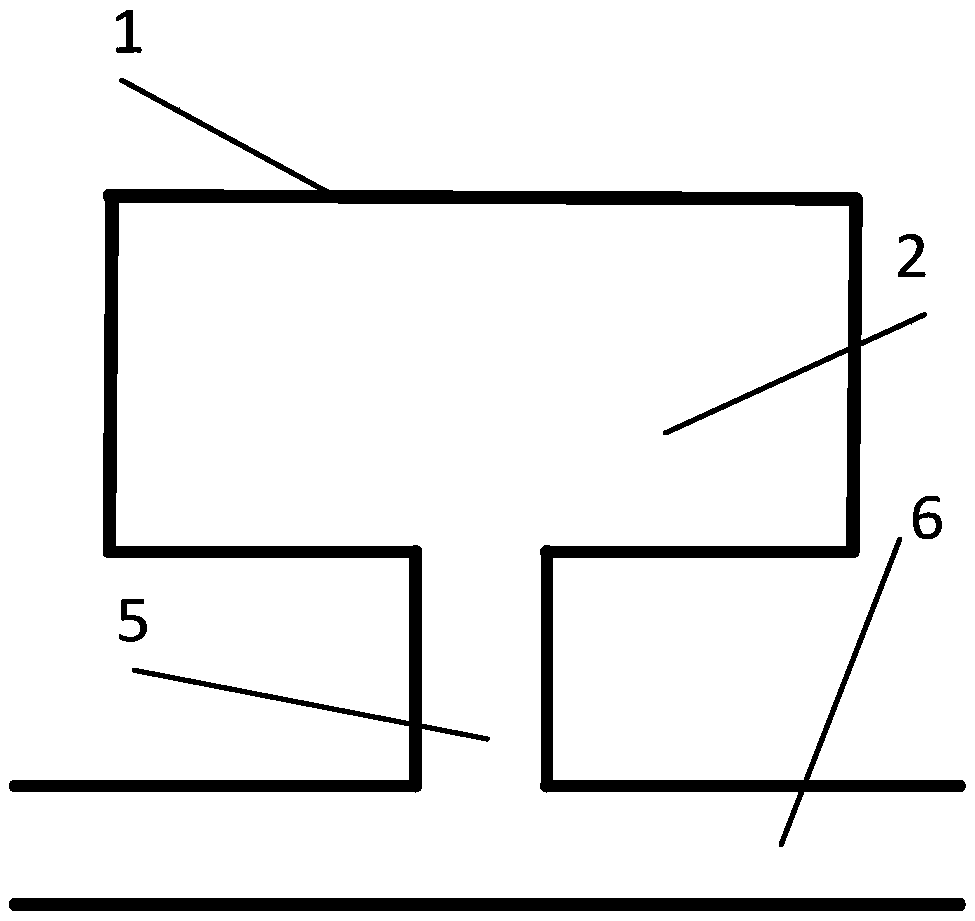

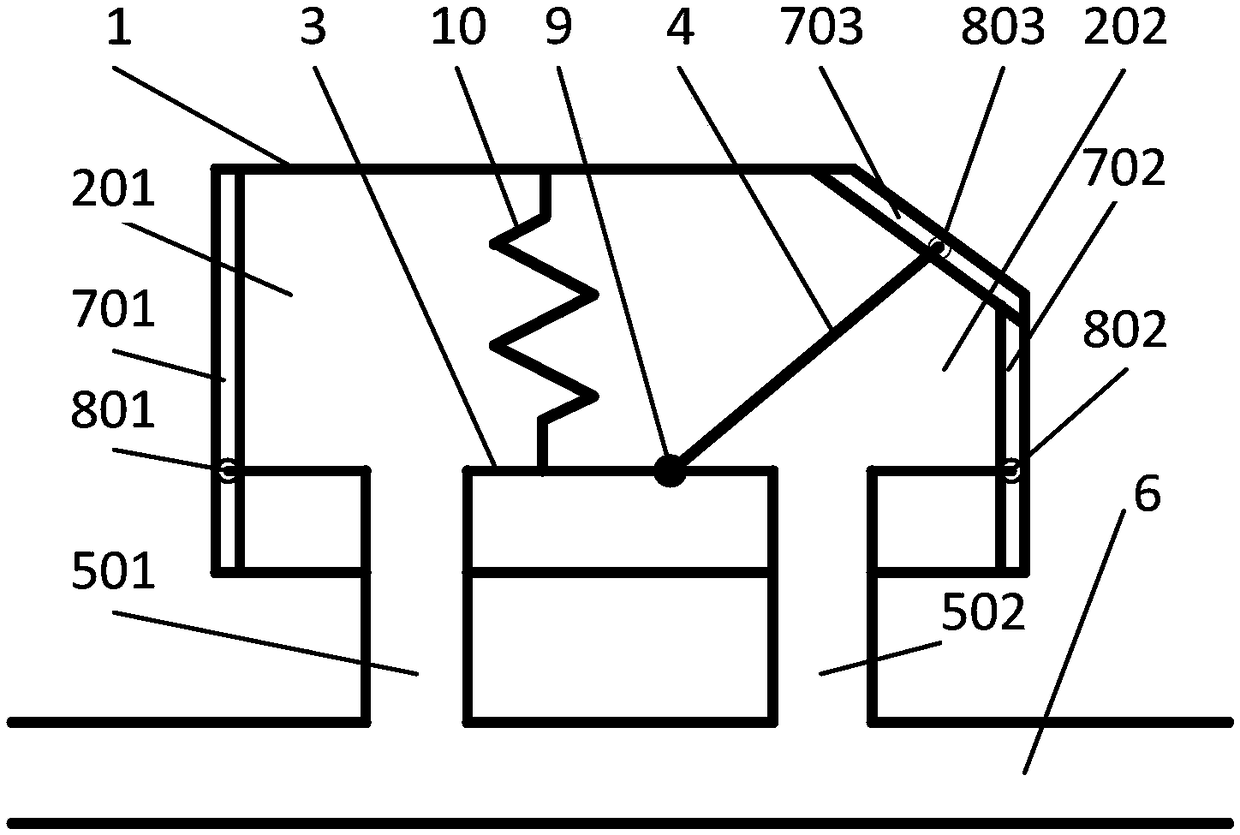

[0020] The basic structure of the preferred embodiment of the present invention and figure 2 The structure in the center is consistent, mainly composed of the muffler shell, two resonant chambers, the bottom plate of the resonant chamber, the partition plate of the resonant chamber, the side branch pipeline, the main pipeline, the track, the roller, the hinge shaft, the return spring and other components, the muffler shell It can move up and down relative to the bottom plate of the resonance cavity through the track, and the partition can rotate around the hinge axis through the track.

[0021] As the flow rate of the medium increases, the negative pressure at the intersection of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com