Oil supply support plate, gas turbine starter and micro gas turbine

A gas turbine and starter technology, which is applied to gas turbine devices, turbine/propulsion fuel delivery systems, fuel flow passages of turbine/propulsion devices, etc. Airfoil loss, improved turbine efficiency, reduced maximum thickness dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

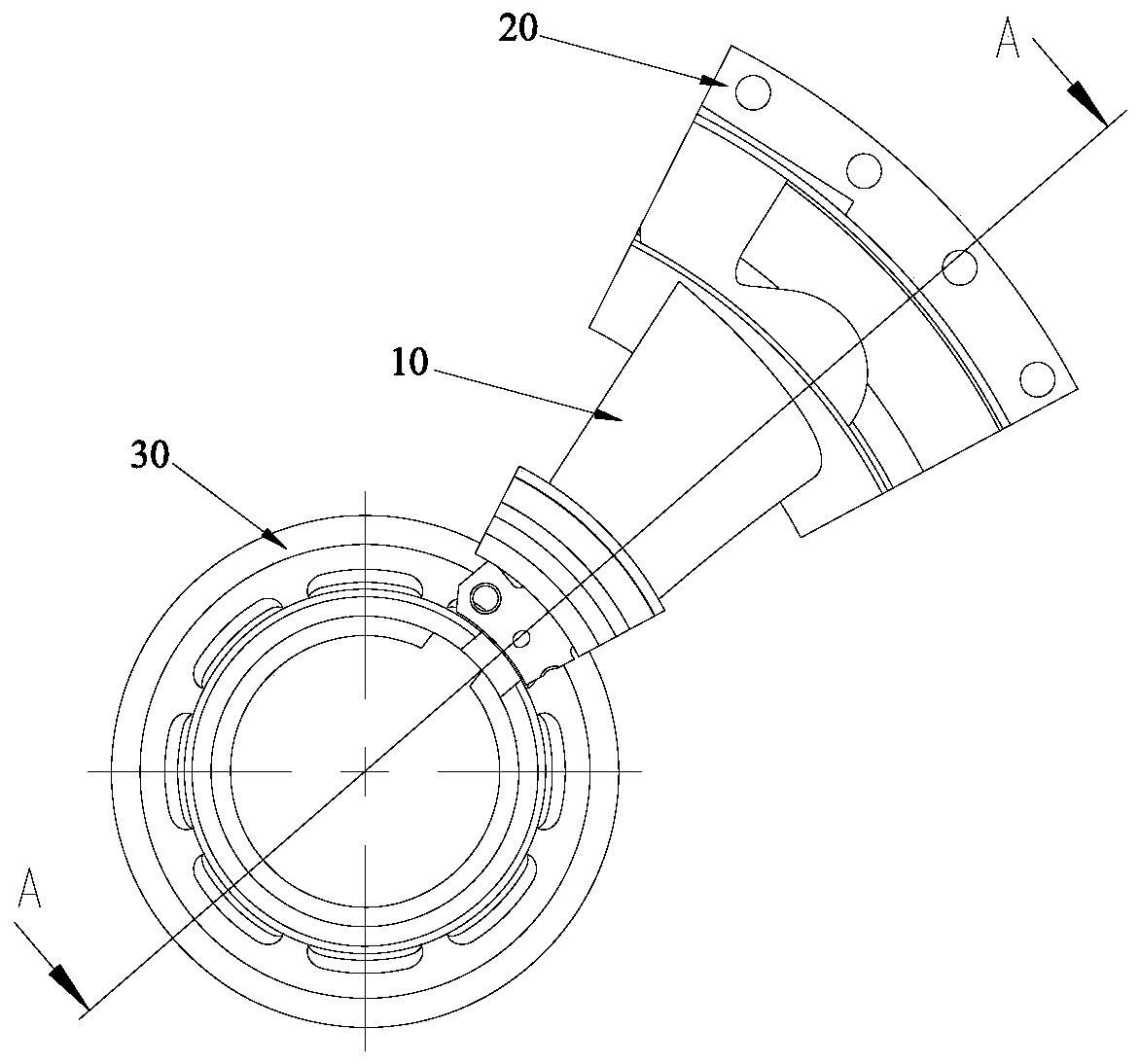

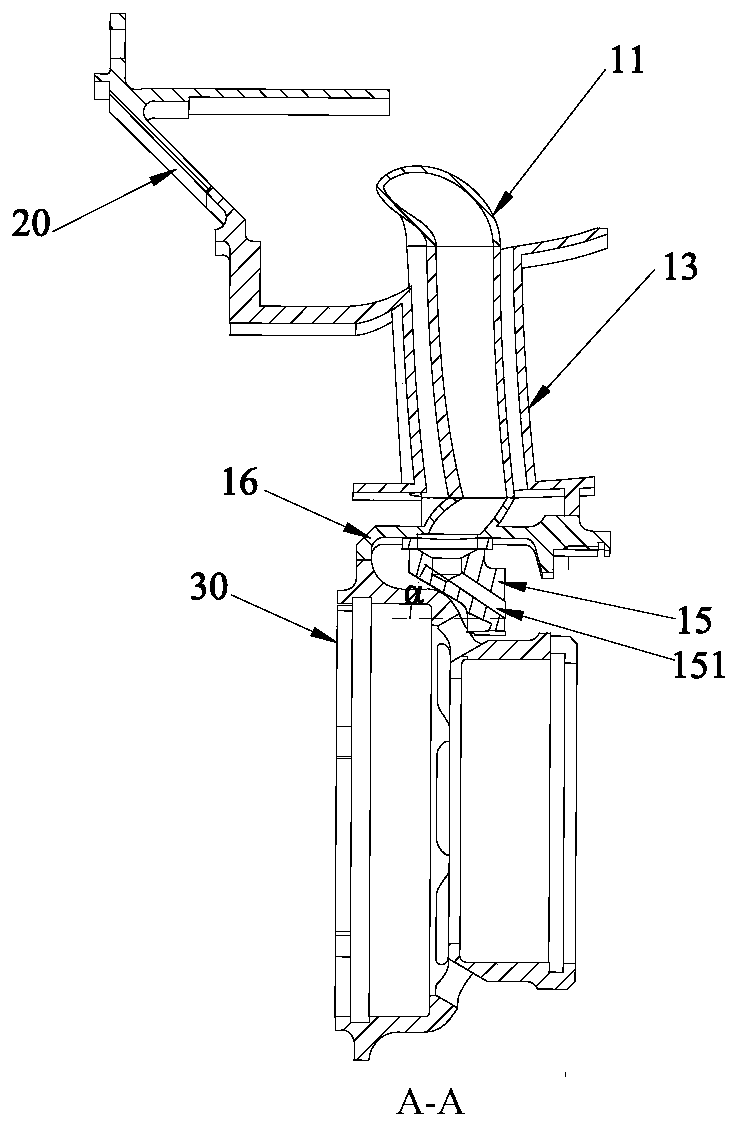

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

[0026] Existing gas turbine starters and miniature gas turbines include bearing housings and guides, wherein the bearing housings need to be lubricated frequently during use to ensure normal operation, and the lubricating oil for lubricating the bearing housings is generally It is introduced by an external oil inlet pipe, and then flows into the lubricating oil nozzle of the bearing seat through the oil supply structure. Among them, the oil supply structure generally uses a lubricating oil inlet pipe inside the pneumatic support plate to connect with the lubricating oil nozzle of the bearing seat. Therefore, the lubricating oil oil inlet pipe needs to be fixedly connected to the oil supply port on the bearing seat and the pneumatic support plate by welding . Howe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com