A column-slab connection device including multiple shear keys

A technology of connecting device and shear key, applied in bridge structure engineering and construction field, can solve problems such as hidden safety hazards of construction workers and clutter on construction site.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

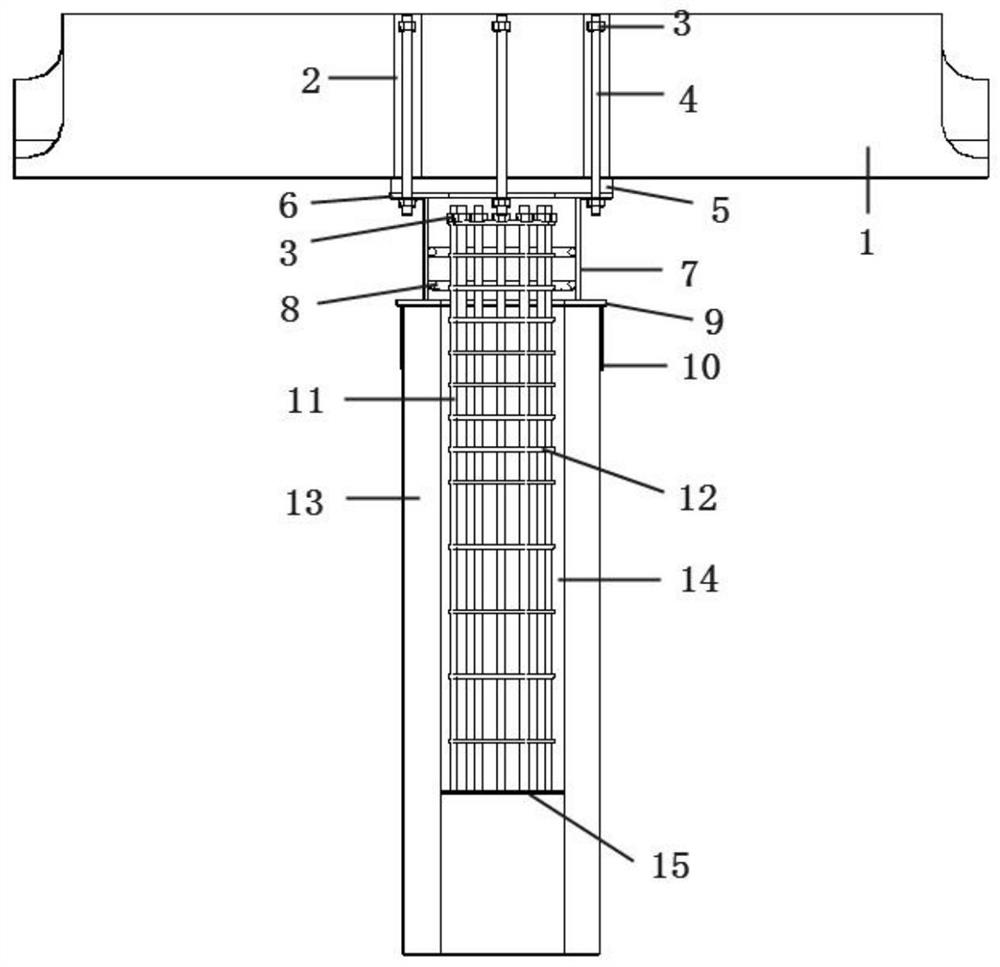

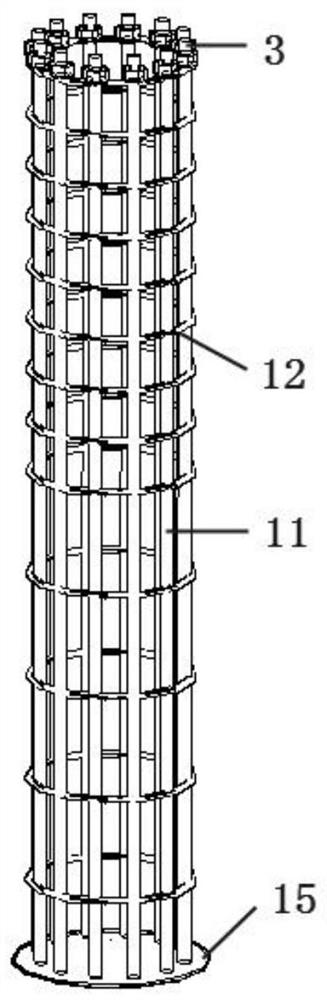

[0023] A column-slab connection device including multiple shear keys, including an upper section assembly, a connection assembly and a lower section assembly.

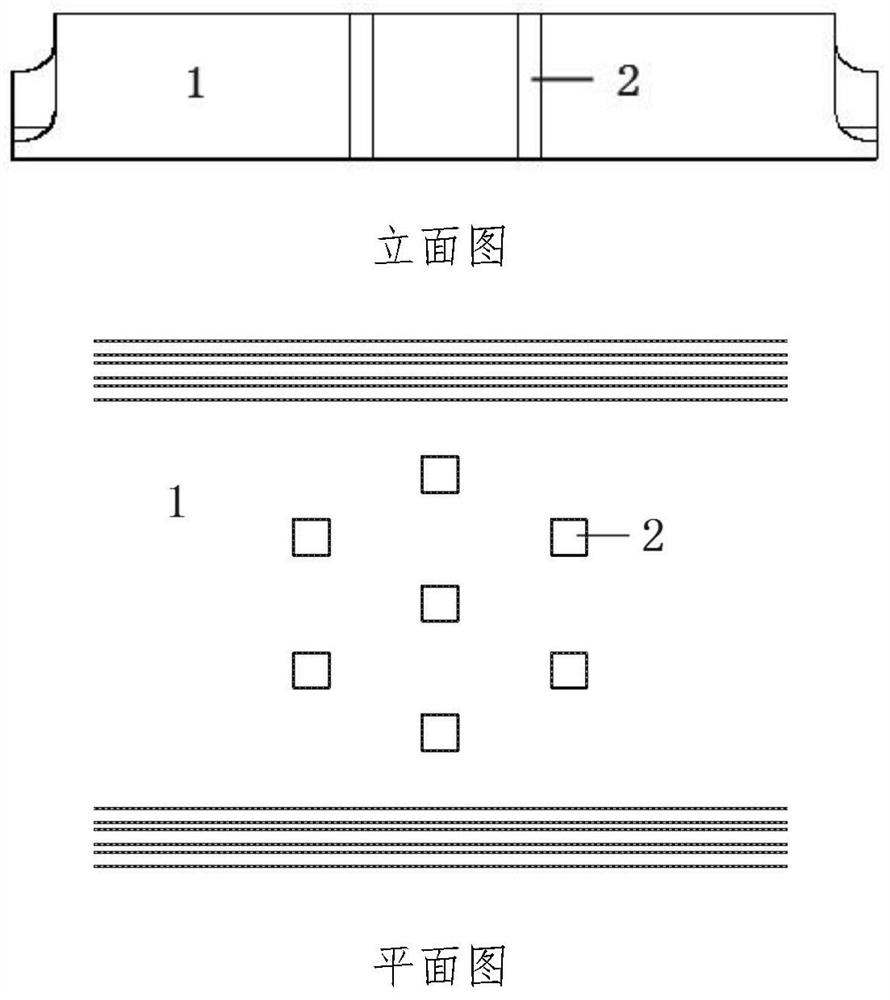

[0024] The upper section assembly includes a prefabricated beam slab 1 . In practice, the prefabricated beam slab 1 includes prefabricated beam slab reserved holes 2 , and the positions of the prefabricated beam slab reserved holes 2 correspond to the positions of the reserved anchor bolt holes on the base steel plate 6 .

[0025] The connection assembly includes a wedge block 5 , a base steel plate 6 , a steel cylinder 7 and a reinforcing hoop 8 on the inner wall of the steel cylinder. During implementation, the wedge block 5 is a cast-in-place or prefabricated structure, which is used for leveling the prefabricated components of the upper section; anchor bolt holes and middle round holes are reserved on the base steel plate 6 for connection with the prefabricated components of the upper section; Tube inner wall rein...

Embodiment 2

[0030] The wedge block 5 can be a prefabricated or cast-in-place component. If the cast-in-place wedge 5 is used, the connection between the upper section component and the connecting component can be implemented by the following methods: hoisting the prefabricated beam slab 1, the prefabricated beam slab 1 is supported by a special bracket, and the center of the beam slab bottom is at a certain distance from the base steel plate 6 . After the positioning and installation of the anchor bolt 4 is completed, the outer formwork of the wedge-shaped block 4 at the bottom of the pouring slab is installed, and then grouting is carried out from the reserved hole 2 of the prefabricated beam slab. The grouting should be full and dense without leaving any voids.

Embodiment 3

[0032] The prefabricated slab 1 can be a prefabricated component or a cast-in-place component. If the cast-in-place beam slab is used, after the positioning and installation of the anchor bolt 4 is completed, on-site grouting with the help of the external formwork is required to realize the connection between the upper section component and the connecting component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com