Slope protection structure for broken rock cutting side slope

A technology of protective structure and slope surface, applied in the direction of foundation structure engineering, excavation, construction, etc., can solve the problems of difficult removal, high engineering cost, damage, etc., to achieve good slope bite, wide application prospects, and enhanced bite force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

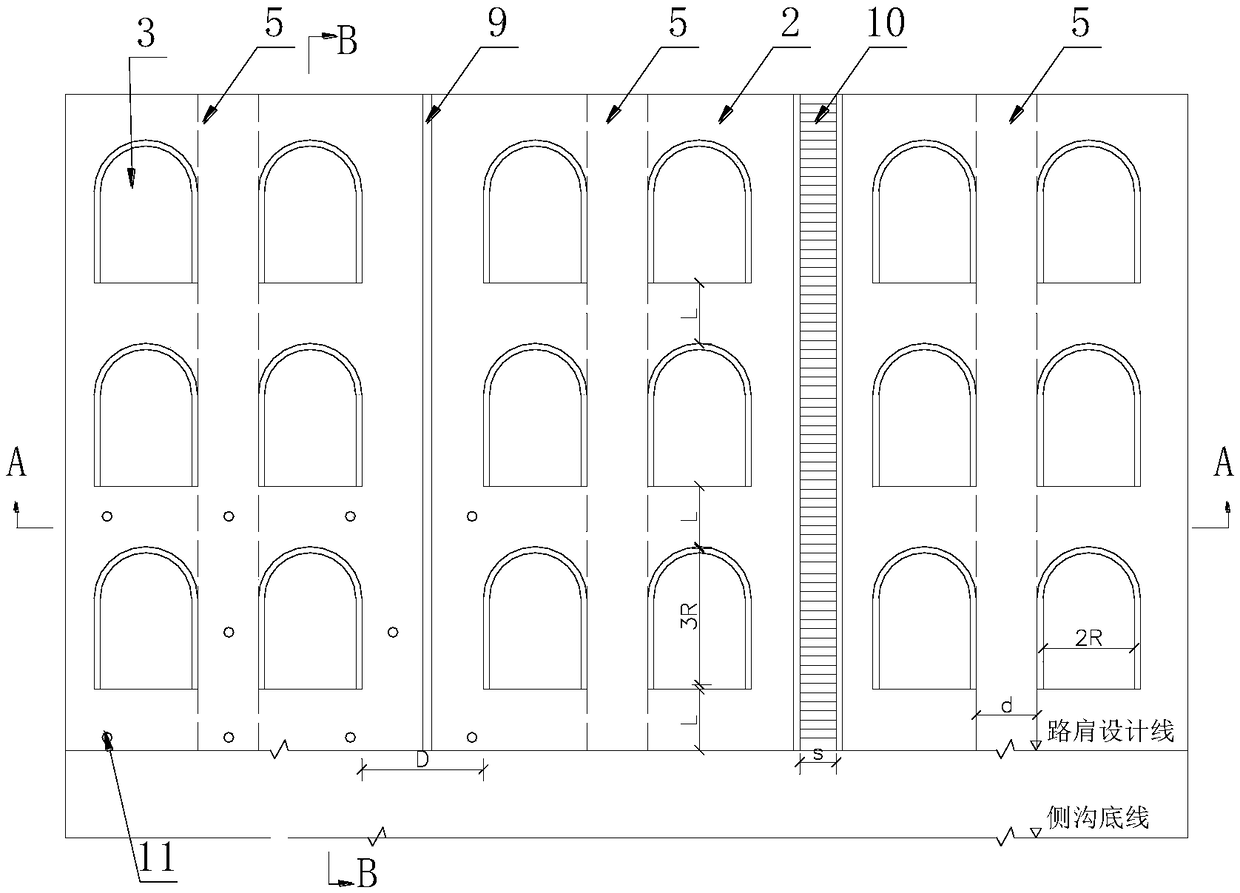

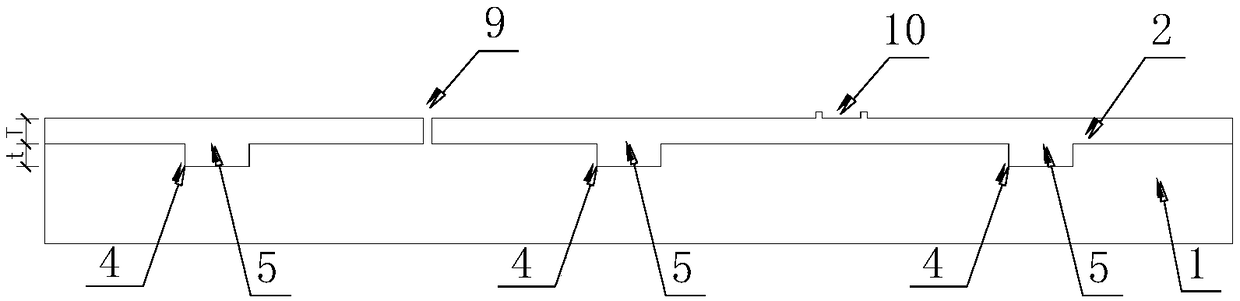

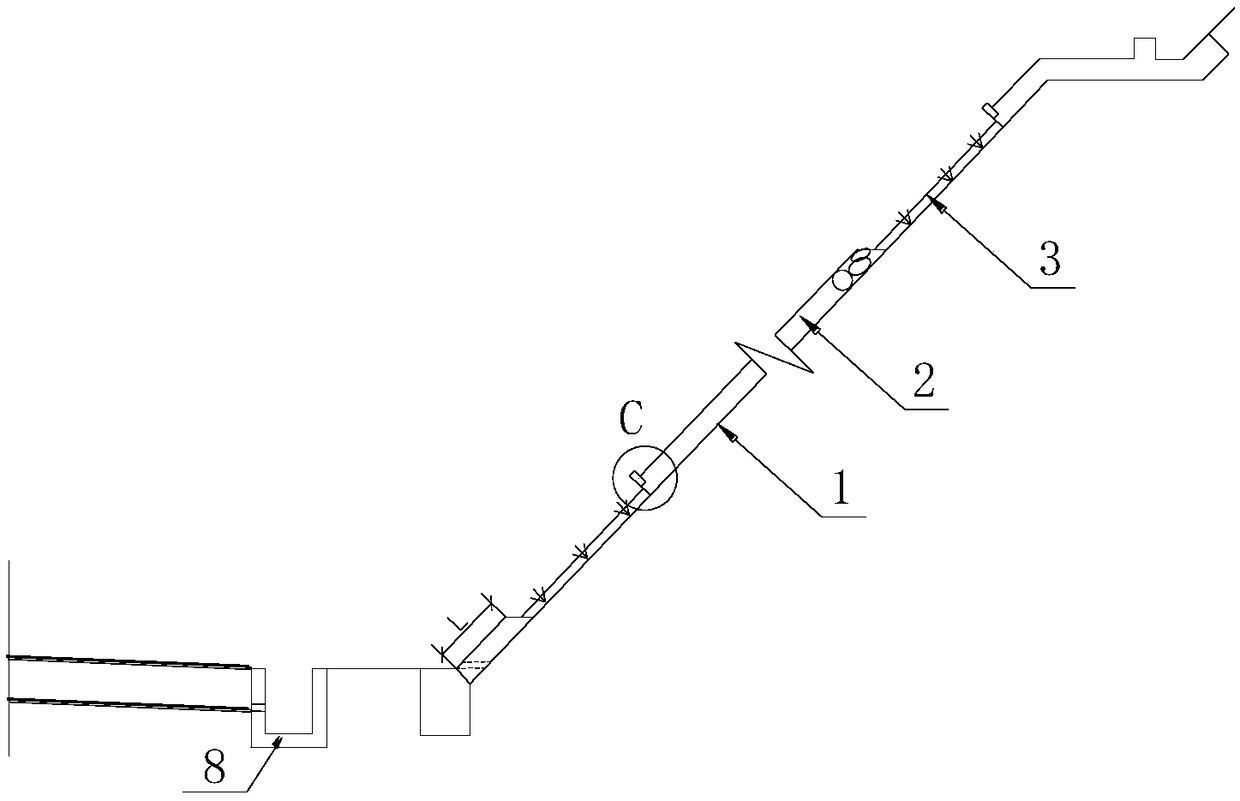

[0029] Such as Figure 1-4 As shown, a kind of slope protection structure for broken rocky cutting slope provided by the present invention comprises an integral hole and window type slope protection wall 2 on the slope surface 1, and the hole and window type slope protection wall 2 is horizontally and vertically Holes and windows 3 are arranged at intervals, the slope surface 1 is concaved along the longitudinal direction to form longitudinal strip grooves 4, and multiple longitudinal strip grooves 4 are arranged at intervals in the transverse direction. Each longitudinal strip foundation 5 is correspondingly embedded in each longitudinal strip groove 4 . The longitudinal strip foundation 5 extends longitudinally over the entire slope. In this embodiment, the vertical direction is taken along the inclined direction of the slope ( figure 1 up and down), along the extension direction of the line is horizontal ( figure 1 center to left).

[0030] The perforated windows 3 on t...

Embodiment 2

[0042] Such as Figure 5-6 As shown, this embodiment is used for the slope protection structure of the broken rock cutting slope, except that the slope surface 1 is concave along the horizontal direction to form a horizontal strip groove 6, and the bottom surface of the hole and window type slope protection wall 2 is provided with a plurality of horizontal strip foundations 7, all the other structures are the same as in Example 1.

[0043]In this embodiment, a plurality of horizontal strip-shaped grooves 6 are vertically spaced apart, and a plurality of horizontal strip-shaped grooves 6 are connected with a plurality of longitudinal strip-shaped grooves 4 to form a grid. The horizontal strip foundation 7, the horizontal strip foundation 7 and the longitudinal strip foundation 5 form a grid-like foundation, and each horizontal strip foundation 7 is correspondingly embedded in each horizontal strip groove 6. The transverse strip foundation 7 extends transversely across the enti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com