Judgment device and method of weaving mode of conductive fabric and type of conductive yarn

A technology of conductive yarn and conductive fabric, which is applied in the field of conductive fabric detection, can solve the problems of difficult to give fast and effective judgment, no fast detection of conductive fabric weaving method, time-consuming and other problems, and achieve accurate and reliable judgment results and simple judgment methods easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0047] Specific embodiment one: Weaving twill conductive fabric at intervals of cotton / conductive filament:

[0048] (1) Multi-point random measurement of the warp or weft direction of the fabric, if there is a certain position under the test, the resistance value is very large, almost exceeding the maximum resistance range of the ordinary multimeter, and the preliminary judgment is that the fabric is separated from the conductive fabric.

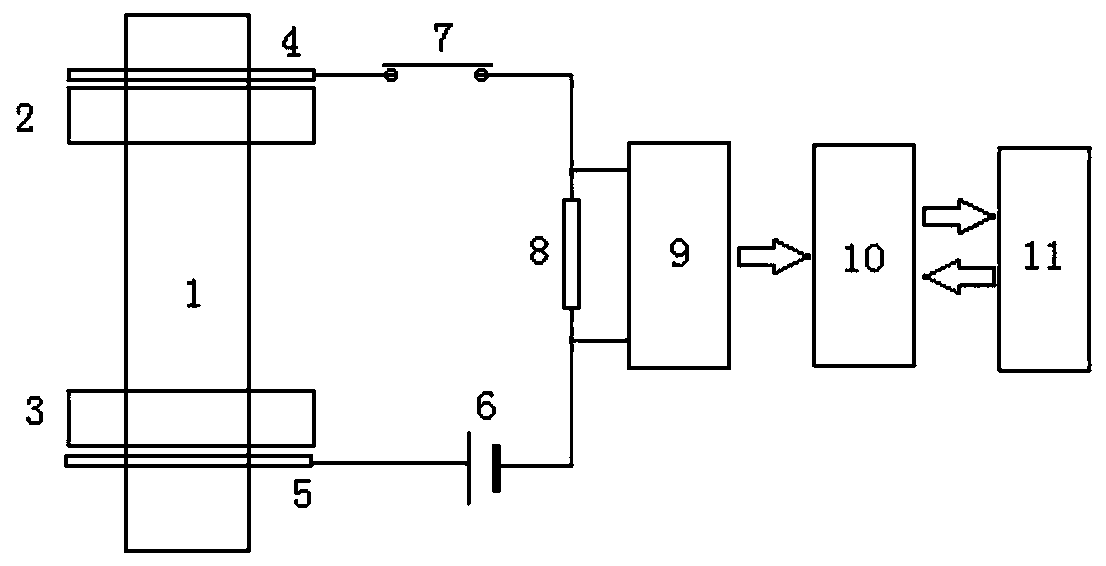

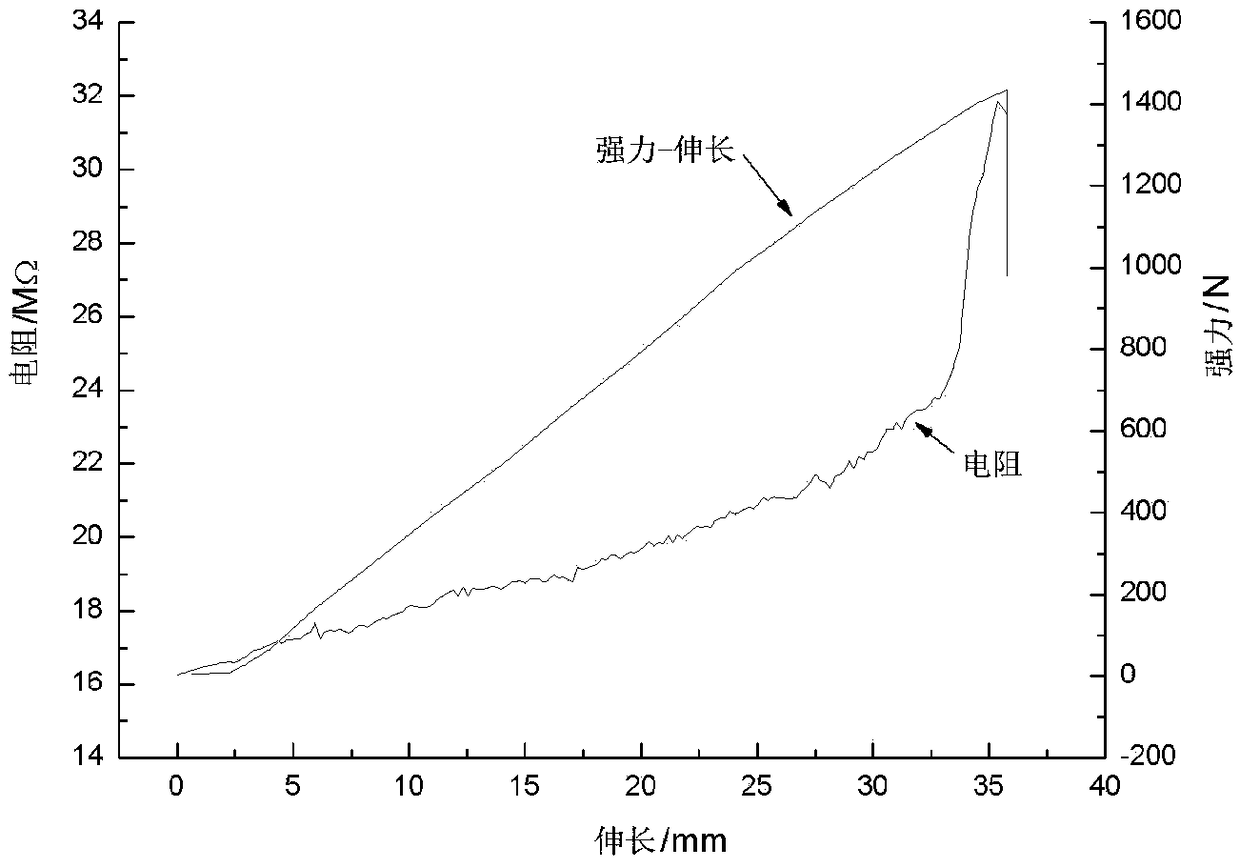

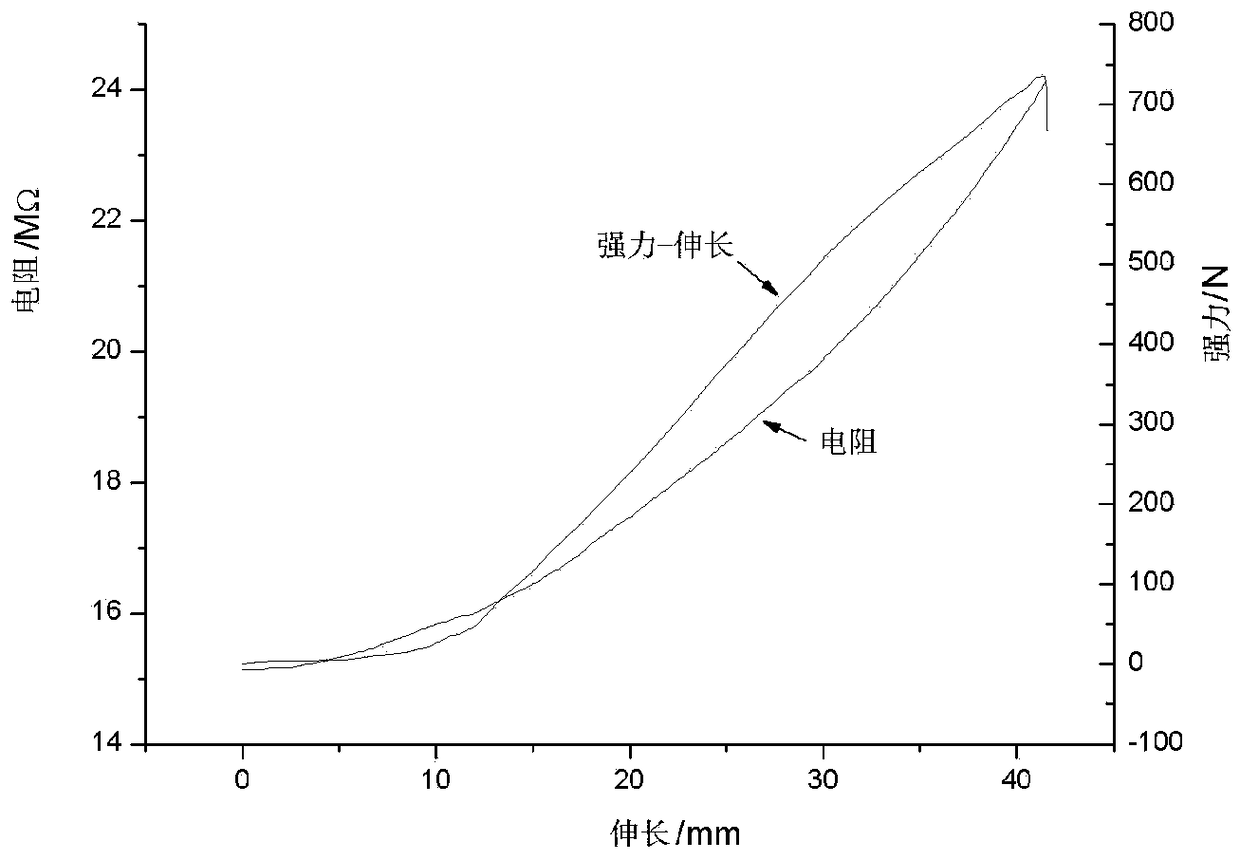

[0049] (2) Insulate the holding mechanism of the fabric tensile strength machine with insulating tape, test the response of resistance or current with stretching during constant speed stretching, and obtain the relationship curve of current or resistance with time or elongation, cotton / conductive The effects of the resistance in the warp direction and weft direction of the twill conductive fabric woven at intervals on the constant-speed stretching process are as follows: figure 2 and image 3 shown. figure 2 It is the meridional resista...

specific Embodiment Embodiment 2

[0051] Specific implementation embodiment two: to the conductive fabric that cotton / stainless steel fiber interval is made;

[0052] (1) Multi-point random measurement of the warp or weft direction of the fabric. If there is a certain position under the test with a very large resistance value under light pressure, which almost exceeds the maximum resistance range of the ordinary meter, it is preliminarily judged that the fabric is separated from the conductive fabric.

[0053] (2) Insulate the holding mechanism of the fabric tensile strength machine with insulating tape, test the response of resistance or current with stretching during constant speed stretching, and obtain the relationship curve of current or resistance with time or elongation, cotton / mixed Responses of the electrical resistance in the warp and weft directions of the twill conductive fabric woven with spinning intervals to the constant-velocity stretching process are as follows: Figure 4 and Figure 5 shown....

specific Embodiment Embodiment 3

[0055] Specific implementation example three: wool / stainless steel fiber blended twill conductive fabric:

[0056] (1) Randomly measure the fabric at multiple points in the warp or weft direction. If the test points have a small resistance value under light pressure, it is preliminarily judged that the fabric is a non-interval conductive fabric.

[0057] (2) Insulate the holding mechanism of the fabric tensile strength machine with insulating tape, test the response of resistance or current with stretching or time during the constant-speed stretching process, and obtain the relationship curve of current or resistance with time or elongation. / Stainless steel fiber blended twill conductive fabric The response of the resistance in the warp direction and weft direction to the constant speed stretching process is as follows Image 6 and Figure 7 shown. Image 6 Response curve of tensile resistance in warp direction of wool / stainless steel fiber blended twill conductive fabric. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com