Leather softening device

A leather and inner drum technology, applied in the direction of leather softening, can solve the problems of affecting service life and poor stability, and achieve the effects of preventing leather from sticking, improving stability and simple structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The best embodiment of the present invention will be further described in detail below.

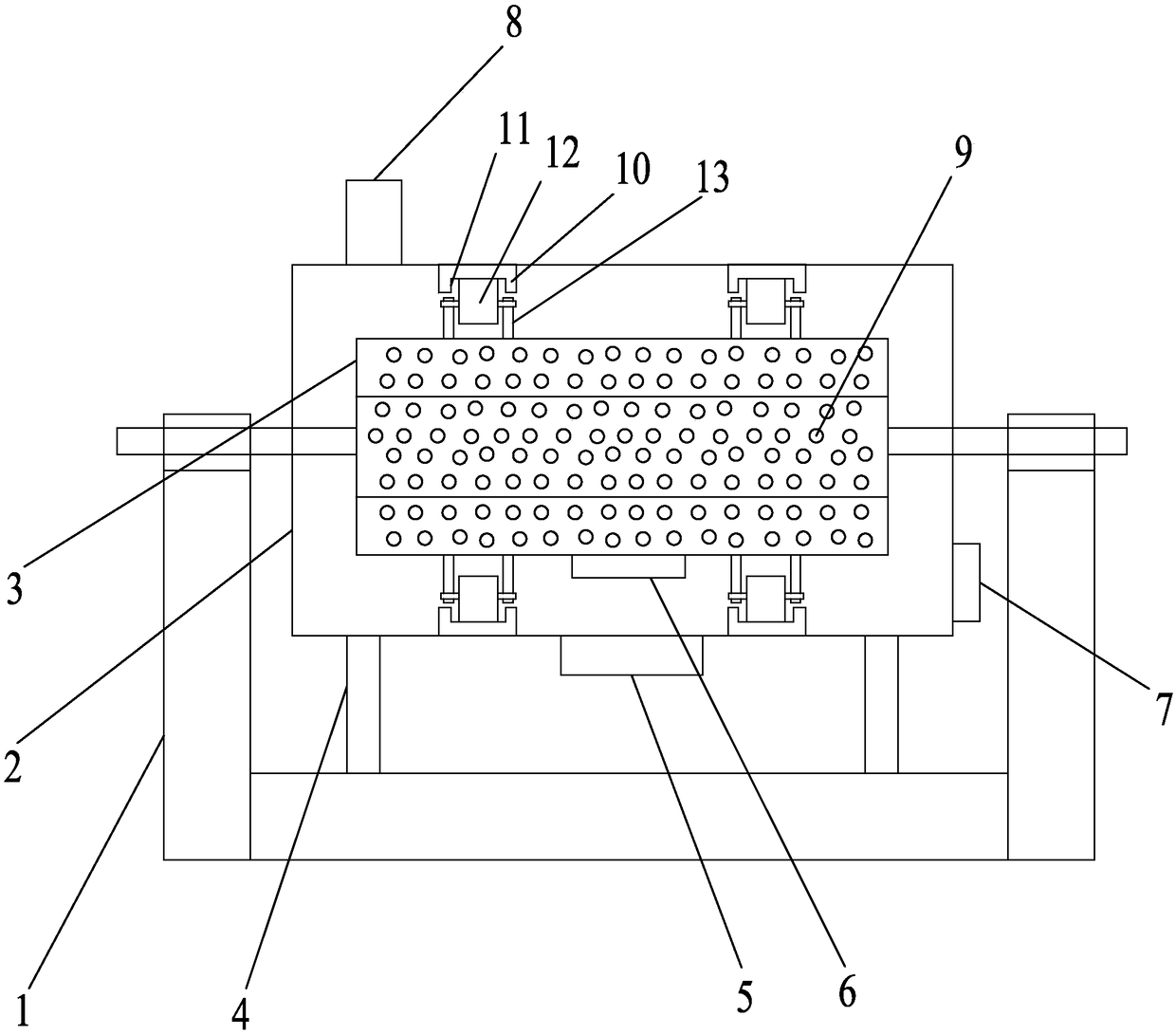

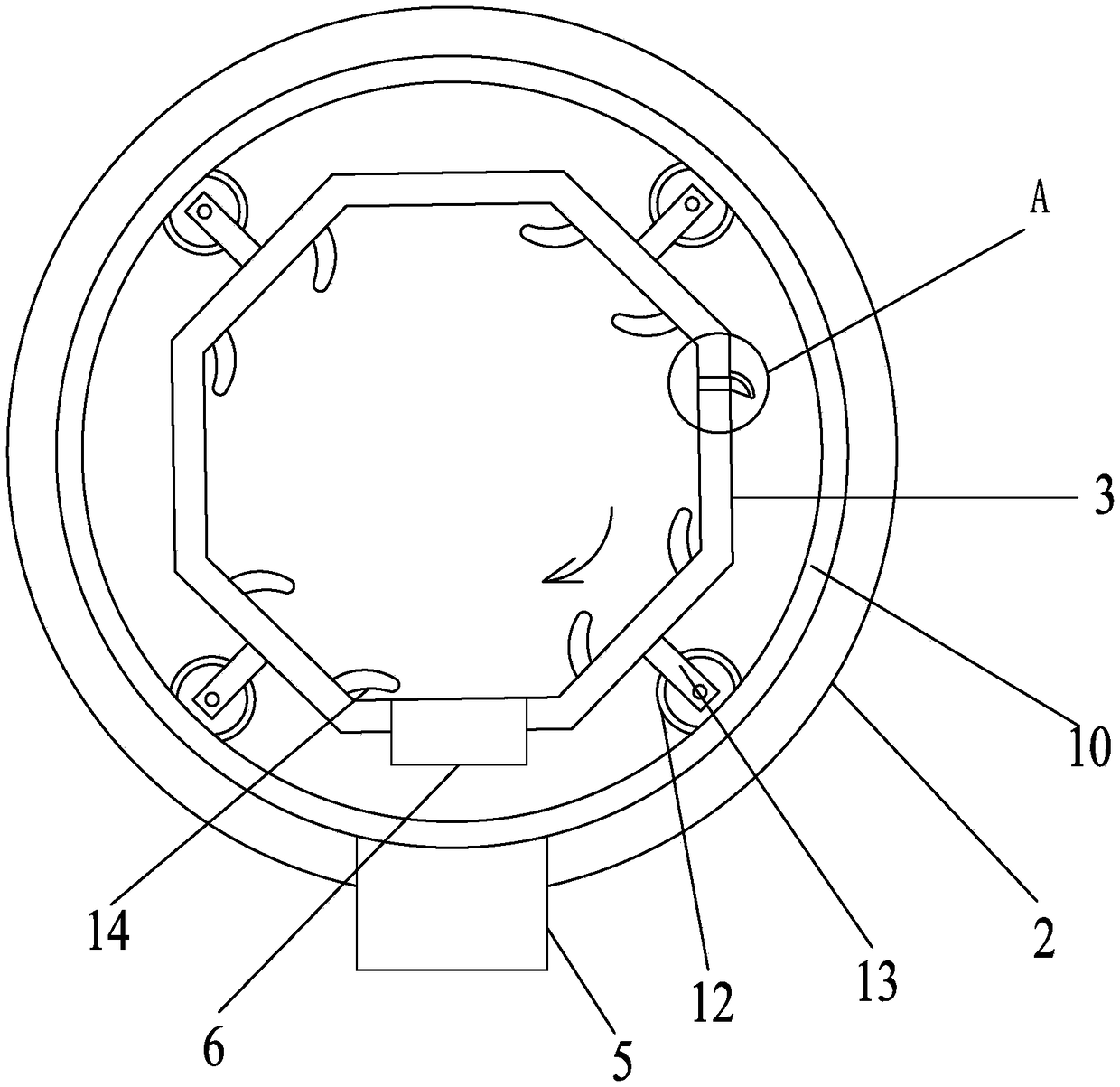

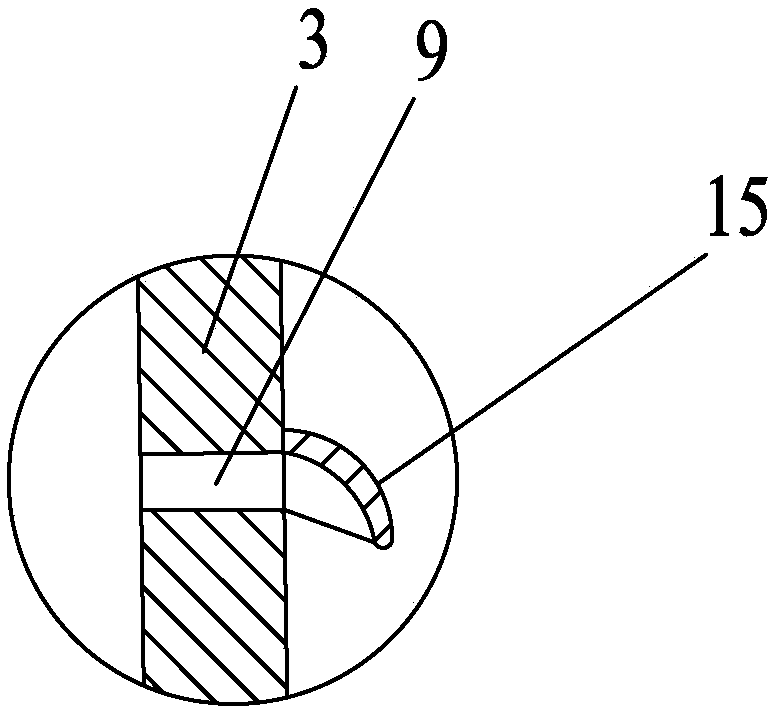

[0019] Such as Figure 1-4 As shown, in the embodiment of the present invention, the leather softening device includes a side frame 1, an outer cylinder 2, an inner drum 3, an outer cylinder support 4, an outer cylinder material opening 5, an inner drum material opening 6, and an air inlet 7. Air outlet 8, ventilation hole 9, support seat 10, groove 11, roller 12, roller bracket 13, baffle plate 14, windshield 15, and the top ends of two side frames 1 arranged side by side respectively connect to the inner drum through the bearing assembly 3 the rotating shaft provided at both ends, the rotating shaft provided at one end of the inner drum 3 is connected to the motor through a synchronous belt to drive the inner drum 3 to rotate; the cross section of the inner drum 3 is polygonal, which can increase the load of leather amount, and improve the soft strength of the leather, the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com