Phase change composite, preparation method and application

A phase-change composite material and powder technology, which is applied in the direction of heat exchange materials, chemical instruments and methods, reagents, etc., can solve the problem of increasing the thermal resistance of heat transfer media and phase change materials, limiting popularization and application, and reducing heat transfer efficiency, etc. problems, to achieve the effect of improving thermal management efficiency, improving heat transfer efficiency, and overcoming low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The type of extruder used in the present invention is TSE35PLUS, with a screw diameter of 35.6mm, a screw aspect ratio of 40, and ten screw heating zones.

[0047] The specific molding method is as follows:

[0048] 1. Primary mixing

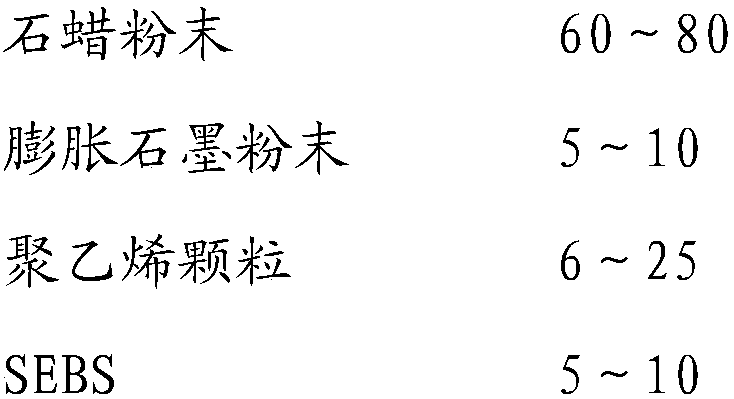

[0049] According to the weight ratio, add 60 parts of paraffin powder, 7 parts of expanded graphite powder, 25 parts of polyethylene particles, 8 parts of SEBS, and 12 parts of flame retardant into a high-speed mixer and mix at a high speed for 30 minutes at 50 ° C to obtain a mixed powder. material.

[0050] 2. Extrude once

[0051] The obtained primary mixed powder is added to the feeding barrel of the extruder. Turn on the power supply, air source and water source, and set the heating temperature of the host screw in the ten areas from the machine head to the feeding port as 120°C, 120°C, 120°C, 110°C, 110°C, 100°C, 100°C, 80°C, 60°C, 40°C; machine head temperature 120°C; start-up valve temperature 120°C; transition plate temperatu...

Embodiment 2

[0065] The weight ratio is 70 parts of paraffin wax powder, 8 parts of expanded graphite powder, 13 parts of polyethylene particles, 9 parts of SEBS, and 14 parts of flame retardant. One-time extrusion set heating temperature The temperature of the ten areas from the machine head to the feeding port is 110°C, 110°C, 110°C, 100°C, 100°C, 90°C, 90°C, 70°C, 50°C, 30°C ; head temperature 110°C; driving valve temperature 110°C; transition plate temperature 110°C; set the contact pressure of the cutter head of the underwater pelletizer to 6kg; The temperature is 140°C, 140°C, 140°C, 130°C, 130°C, 120°C, 120°C, 100°C, 80°C, 60°C; the head temperature is 140°C; the start valve temperature is 140°C; the transition plate temperature is 140°C ; Setting underwater granulator cutter head contact pressure 8kg; Other steps are with embodiment 1.

[0066] The phase-change composite material pellets obtained in this example were thermocompressed to obtain a 5mm thick sheet, and performance te...

Embodiment 3

[0068] The weight ratio is 80 parts of paraffin wax powder, 9 parts of expanded graphite powder, 6 parts of polyethylene particles, 5 parts of SEBS, and 14 parts of flame retardant.

[0069] The specific preparation steps are the same as in Example 1.

[0070] The phase-change composite material pellets obtained in this example were thermocompressed to obtain a 5mm thick sheet, and performance tests were performed on it. The specific performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com