A three-dimensional graphene composite material that can be used as a strain sensor and its preparation method

A composite material and graphene technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of easy damage, poor designability of strain sensor, high expansion rate and sensitivity, etc., so as to avoid structural damage , Improve the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

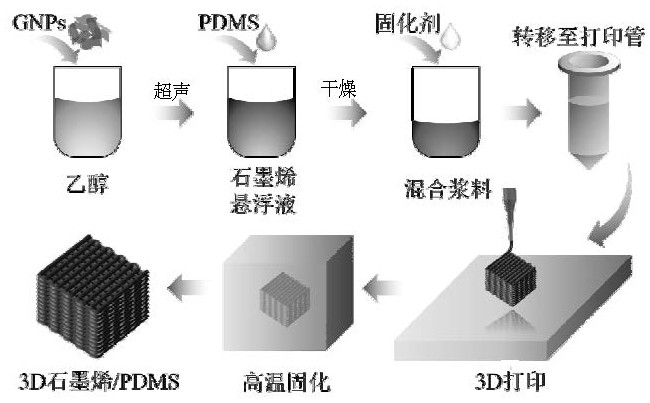

[0040] (1) ethylene glycol butyl ether and dibutyl phthalate are mixed as a dispersant with a mass ratio of 2:1, and then graphene and a dispersant are added in ethanol with a mass ratio of 1:1, wherein graphene The mass ratio with ethanol is 1:150, and then ultrasonic 2h under 200W power, obtains the graphene suspension that disperses uniformly; Then add PDMS and solidifying agent that mass ratio is 10:1 to suspension (solidifying agent and PDMS produce From the same manufacturer, used together), ultrasonicated for 2 hours at 200W power, in which the mass ratio of graphene to PDMS was 1:5; after being uniformly mixed, placed in a ventilated place to dry naturally, and the printing paste was obtained after the ethanol was completely volatilized;

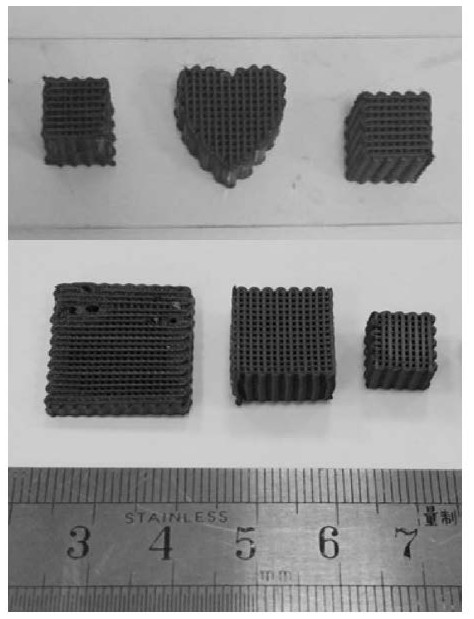

[0041] (2) Transfer the slurry to the printing tube, and import it into the computer control terminal with a size of 10×10×8mm 3 The block model is then superimposed layer by layer to print out the sample of the three-dimensional str...

Embodiment 2

[0044] (1) ethylene glycol butyl ether and dibutyl phthalate are mixed as a dispersant with a mass ratio of 2:1, and then graphene and a dispersant are added in ethanol with a mass ratio of 1:1, wherein graphene The mass ratio with ethanol is 1:150, and then ultrasonic 2h under 200W power, obtains the graphene suspension that disperses uniformly; Then add PDMS and solidifying agent that mass ratio is 10:1 to suspension (solidifying agent and PDMS produce From the same manufacturer, used together), ultrasonicated for 2 hours at 200W power, in which the mass ratio of graphene to PDMS was 1:6; after being uniformly mixed, placed in a ventilated place to dry naturally, and the printing paste was obtained after the ethanol was completely volatilized;

[0045] (2) Transfer the slurry to the printing tube, and import it into the computer control terminal with a size of 10×10×8mm 3 The block model is then superimposed layer by layer to print out the sample of the three-dimensional str...

Embodiment 3

[0048] (1) ethylene glycol butyl ether and dibutyl phthalate are mixed as a dispersant with a mass ratio of 2:1, and then graphene and a dispersant are added in ethanol with a mass ratio of 1:1, wherein graphene The mass ratio with ethanol is 1:150, and then ultrasonic 2h under 200W power, obtains the graphene suspension that disperses uniformly; Then add PDMS and solidifying agent that mass ratio is 10:1 to suspension (solidifying agent and PDMS produce From the same manufacturer, used together), ultrasonicated for 2 hours at 200W power, in which the mass ratio of graphene to PDMS was 1:7; after being uniformly mixed, placed in a ventilated place to dry naturally, and the printing paste was obtained after the ethanol was completely volatilized;

[0049] (2) Transfer the slurry to the printing tube, and import it into the computer control terminal with a size of 10×10×8mm 3 The block model is then superimposed layer by layer to print out the sample of the three-dimensional str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com