Preparation for improving stability of biological membrane of movable bed biological membrane reactor and application of preparation

A technology for stabilizing preparations and biofilms, applied in the field of preparations for enhancing the stability of biofilms in moving bed biofilm reactors, can solve problems such as the difficulty in maintaining microbial activity in sludge, achieve good environmental and economic benefits, and reduce intermediate and intraspecies Competition, cost-effective formation and stabilization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Reagent preparation process:

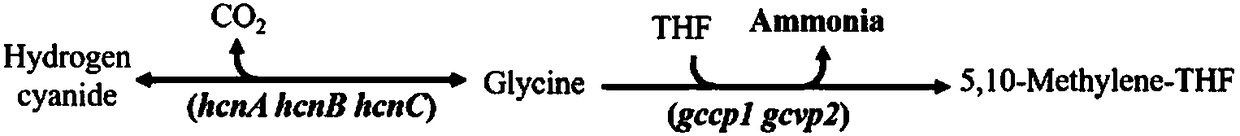

[0059] Population stabilizer: 55kg of ammonium sulfate, 30kg of 5,10-methylene-tetrahydrofuran; coating agent: 20kg of chitosan. The above-mentioned ammonium sulfate and coating agent chitosan are weighed according to the mass percentage of each component, then dried, dissolved and mixed; put into a mixer and mixed and stirred evenly, after stirring for more than 30 minutes, sieve with a sieve of more than 200 mesh, and filter out larger particle. The obtained powder was slowly dissolved in 5,10-methylene-tetrahydrofuran.

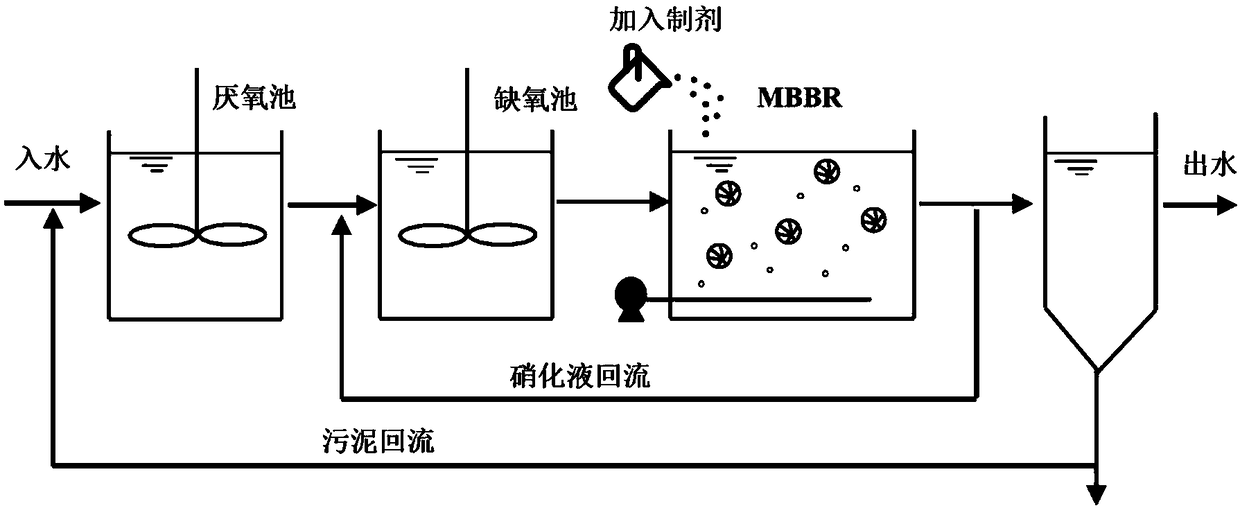

[0060] (2) Sample loading conditions: the preparation prepared by the present invention enters the reactor in the following feeding manner. The dosing place is the MBBR reactor, and the sampling frequency is once every 5 days. The dosage of the dosing preparation is listed in Table 1.

[0061] (3) Detection index: Observe the COD value of the MBBR reactor influent and effluent. When the COD removal rate is stable...

Embodiment 2

[0063] (1) Reagent preparation process:

[0064] Population stabilizer: 55kg of ammonium sulfate, 30kg of 5,10-methylene-tetrahydrofuran; coating agent: 20kg of chitosan. The above-mentioned ammonium sulfate and coating agent chitosan are weighed according to the mass percentage of each component, then dried, dissolved and mixed; put into a mixer and mixed and stirred evenly, after stirring for more than 30 minutes, sieve with a sieve of more than 200 mesh, and filter out larger particle. The obtained powder was slowly dissolved in 5,10-methylene-tetrahydrofuran.

[0065] (2) Sample loading conditions: the preparation prepared by the present invention enters the reactor in the following feeding manner. The dosing place is the MBBR reactor, and the sampling frequency is once every 7 days. The dosage of the dosing preparation is listed in Table 1.

[0066] (3) Detection index: Observe the COD value of the MBBR reactor influent and effluent. When the COD removal rate is stable...

Embodiment 3

[0068] (1) Reagent preparation process:

[0069] Population stabilizer: 55kg of ammonium sulfate, 30kg of 5,10-methylene-tetrahydrofuran; coating agent: 20kg of chitosan. The above-mentioned ammonium sulfate and coating agent chitosan are weighed according to the mass percentage of each component, then dried, dissolved and mixed; put into a mixer and mixed and stirred evenly, after stirring for more than 30 minutes, sieve with a sieve of more than 200 mesh, and filter out larger particle. The obtained powder was slowly dissolved in 5,10-methylene-tetrahydrofuran.

[0070] (2) Sample loading conditions: the preparation prepared by the present invention enters the reactor in the following feeding manner. The dosing place is the MBBR reactor, and the sampling frequency is once every 10 days. The dosage of the dosing preparation is listed in Table 1.

[0071] (3) Detection index: Observe the COD value of the MBBR reactor influent and effluent. When the COD removal rate is stabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com