Method for improving methane production efficiency of sulfate organic wastewater

A technology for organic wastewater and sulfate, applied in chemical instruments and methods, water pollutants, waste fuels, etc., to achieve the effect of improving the methane production efficiency of sulfate organic wastewater, avoiding processes, and strengthening competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

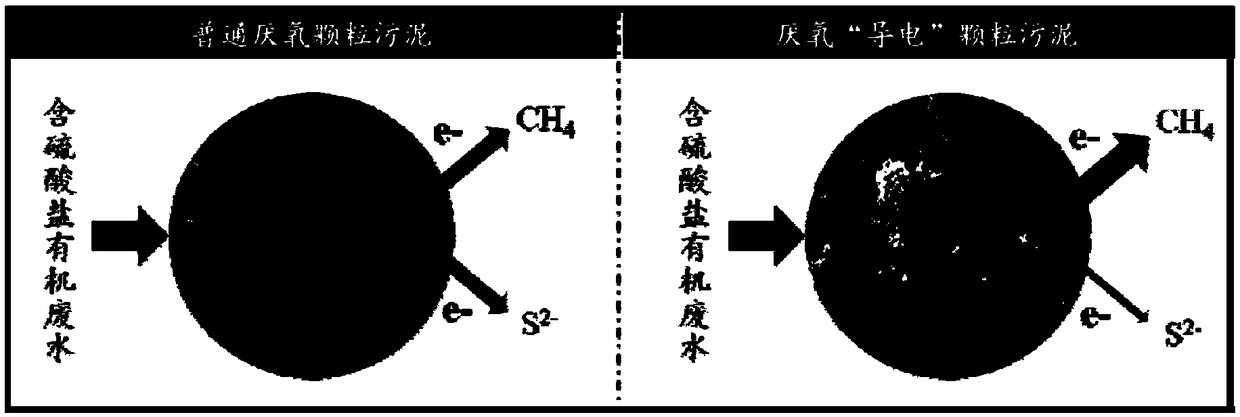

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) UASB reactor is used to inoculate the sludge from the anaerobic reactor of the sewage treatment plant. The VSS concentration of the inoculated sludge is about 50g / L. The sludge contains a large number of anaerobic microorganisms with high activity.

[0023] (2) if figure 2 As shown, the total volume of the reactor is 5.6L, the volume of the reaction zone is 2.9L, the inner diameter is 0.7dm, and the height is 10.6dm. The three sampling ports are distributed at 5.2dm, 7.2dm and 10.6dm respectively. A peristaltic pump is used to control the water inflow rate. A gas flow meter was installed at the outlet of the reactor to measure the volume of gas produced.

[0024] (3) Add 1.5g / L of single-walled carbon nanotubes, that is, 4.35g in the reactor, and the dosage is more than the theoretical value (1g / L), so as to prevent the loss of some carbon nanotubes during the start-up process.

[0025] (4) The reactor was aerated with nitrogen with a purity greater than 99.99%,...

Embodiment 2

[0031] Same as Example 1, the difference is that the dosage of single-walled carbon nanotubes is 2.0g / L, and the final result can be obtained: Compared with the ordinary anaerobic granular sludge system, the anaerobic "conductive" granular sludge The methane yield in the system increased by 21.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com