Intelligent control method, device and system for preventing sensor damage

An intelligent control and sensor technology, which is applied in the direction of conveyor control devices, transportation and packaging, conveyors, etc., can solve problems such as failure to detect in time, sensor damage, etc., and achieve the effect of avoiding sensor damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

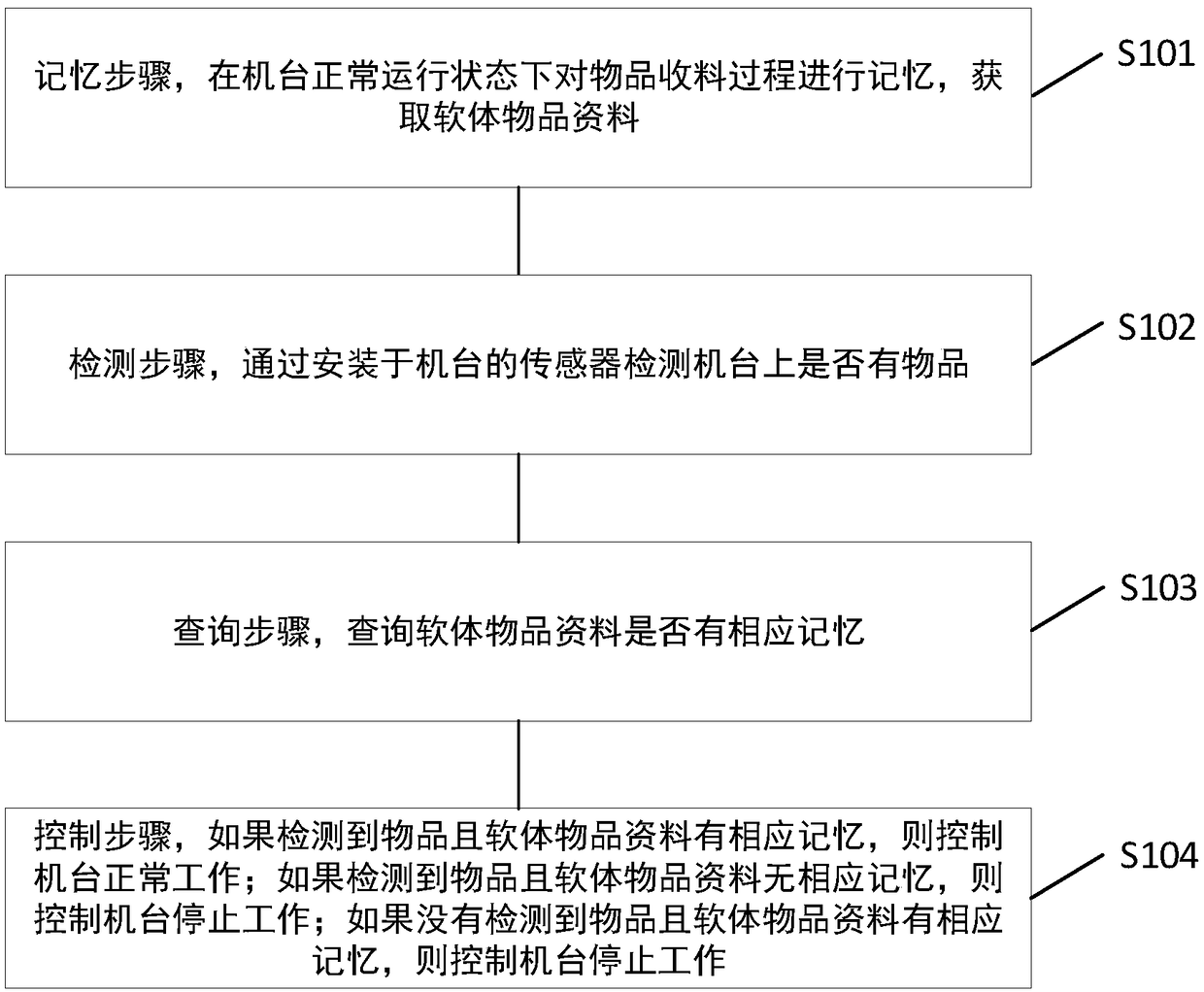

[0049] Such as figure 1 As shown, the embodiment of the present invention provides an intelligent control method for preventing sensor damage, including:

[0050] Memorizing step S101, memorizing the material receiving process of the machine under the normal operation state of the machine, and obtaining software material data;

[0051] Detection step S102, detecting whether there is an item on the machine through a sensor installed on the machine;

[0052] Inquiry step S103, inquire whether the software item data has corresponding memory;

[0053] Control step S104, if an item is detected and the software item data has a corresponding memory, the control machine works normally; if an item is detected and the software item data has no corresponding memory, the control machine stops working; if no item is detected and the software item If the data has corresponding memory, the control machine will stop working.

[0054] The embodiment of the present invention does not limit t...

specific Embodiment 2

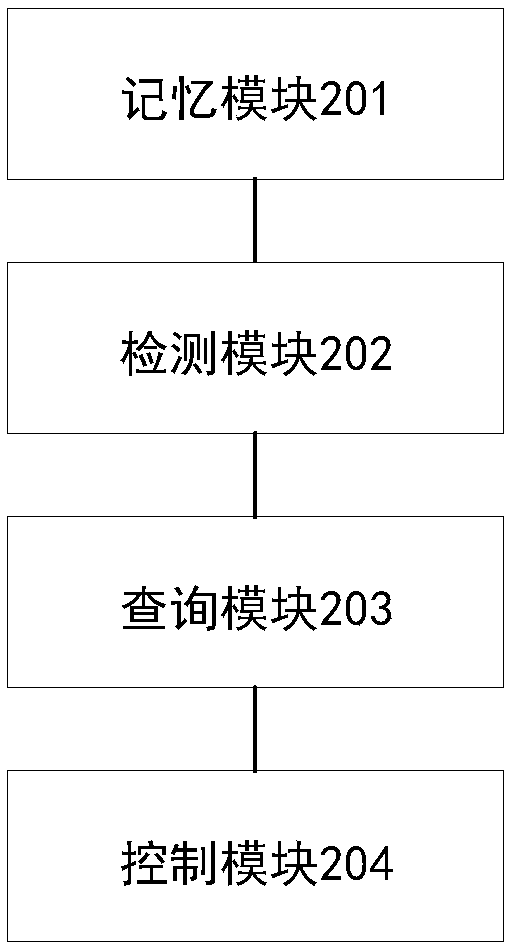

[0060] Such as figure 2 As shown, the embodiment of the present invention provides an intelligent control device for preventing sensor damage, including:

[0061] The memory module 201 is used to memorize the material receiving process of the machine under the normal operation state of the machine, and obtain software material data;

[0062] The detection module 202 is used to detect whether there is an item on the machine through a sensor installed on the machine;

[0063] Inquiry module 203, used to inquire whether the software item data has corresponding memory;

[0064] The control module 204 is used to control the machine to work normally if an item is detected and the software item data has corresponding memory; if an item is detected and the software item data has no corresponding memory, then the control machine stops working; if no item is detected and If the software item data has a corresponding memory, the control machine will stop working.

[0065] In the embo...

specific Embodiment 3

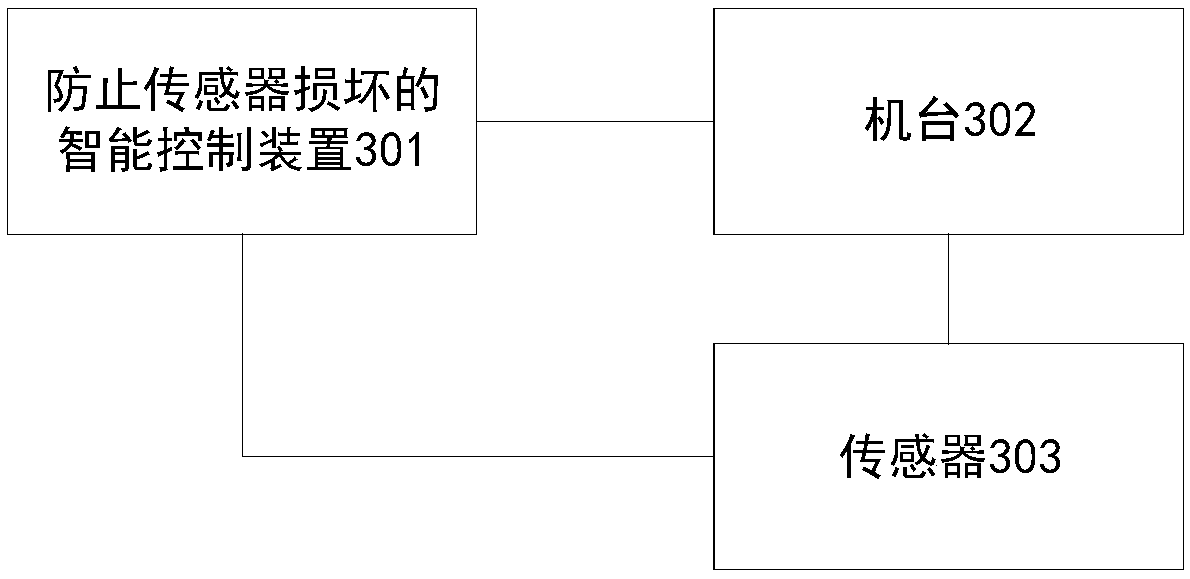

[0068] Such as image 3 As shown, the embodiment of the present invention provides an intelligent control system for preventing sensor damage, including:

[0069] The intelligent control device 301 for preventing sensor damage in the specific embodiment 2; and those respectively connected with the intelligent control device 301:

[0070] Machine platform 302, used for receiving items;

[0071] The sensor 303 is installed on the machine platform 302 and is used to detect whether there is an item on the machine platform 302 .

[0072] The embodiment of the present invention does not limit the machine platform, preferably, the machine platform 302 may be a material receiving motion platform.

[0073] In the embodiment of the present invention, firstly, in the normal operation state of the machine, during the process of the manipulator transporting the items to the machine and receiving the items, the software memory is performed on the received items and their receiving informa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com