Large thermal insulation box equipment based on independent node installation

A technology of independent nodes and heat preservation boxes, applied in the field of industrial heat preservation, can solve the problems of increased difficulty in processing and manufacturing heat preservation boxes, increased maintenance and repair costs, increased difficulty, and low applicability of temperature sensors, so as to eliminate the problem of weak engagement and avoid Effect of sensor damage and heat loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

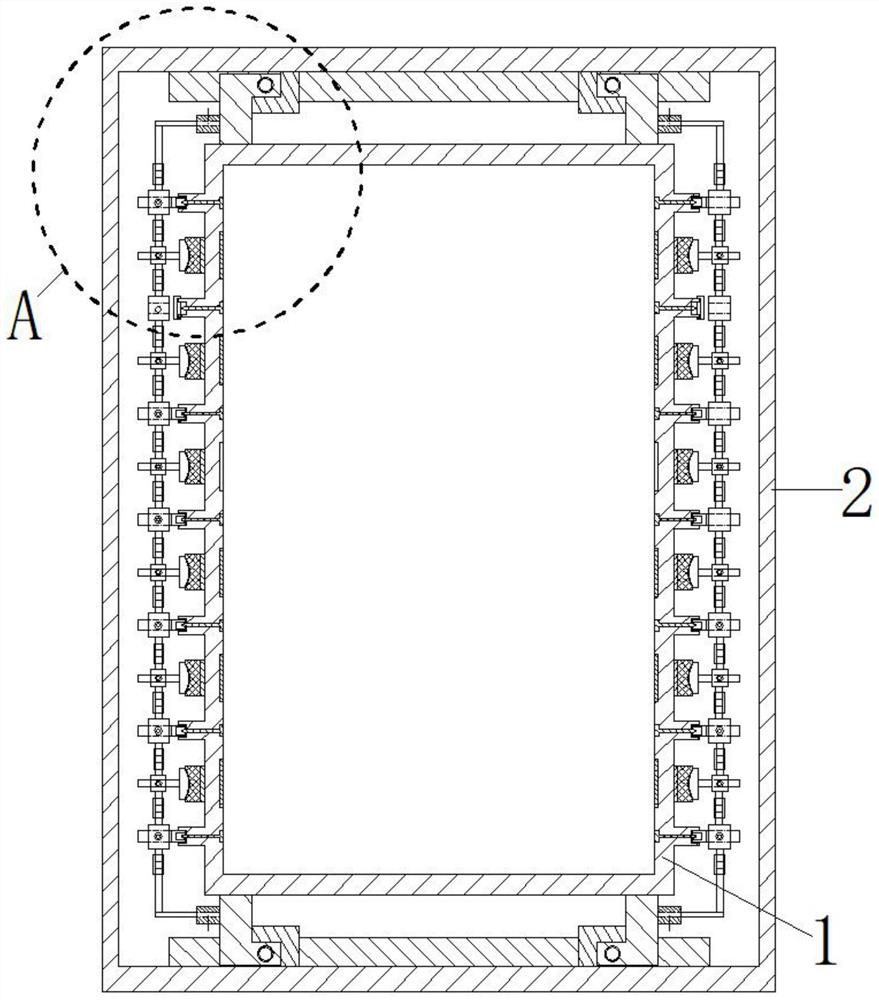

[0041] like Figure 1 to Figure 8 , The invention is a large-scale incubator equipment based on independent node installation and measurement and control.

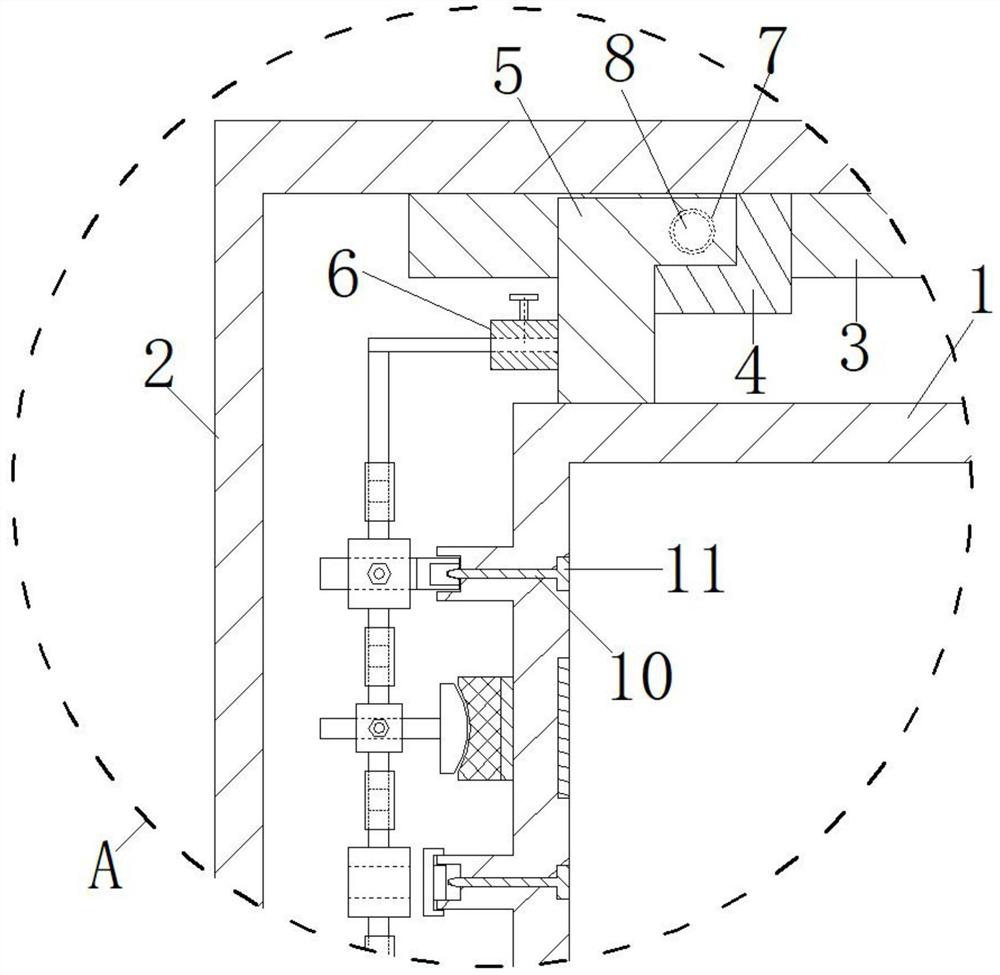

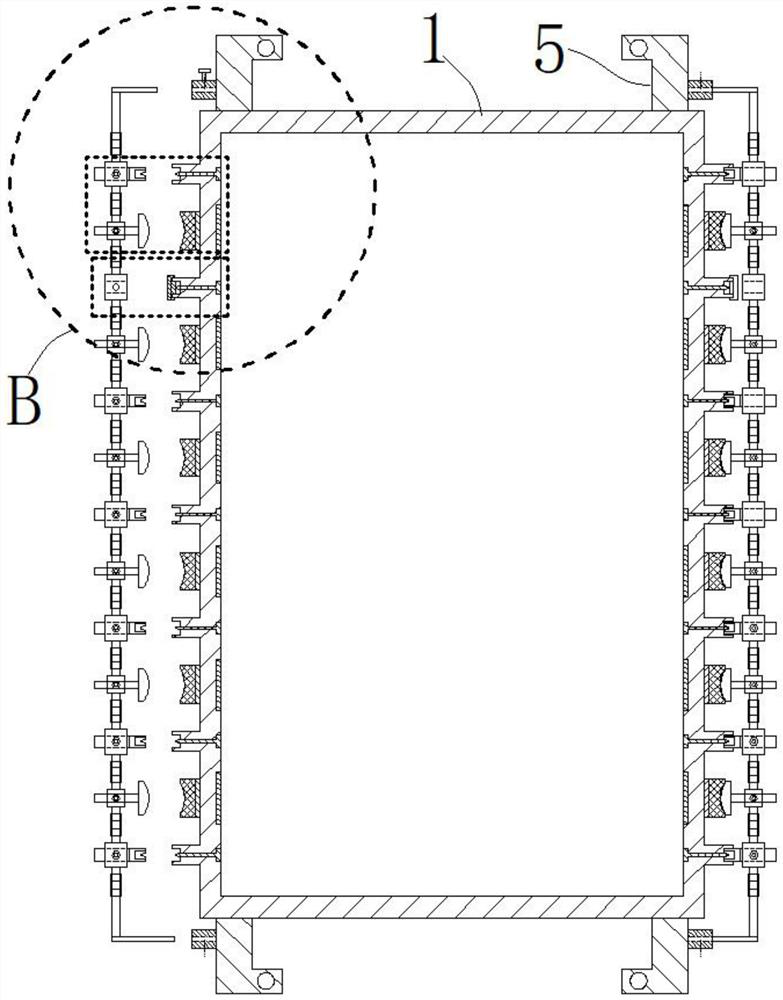

[0042] see figure 2 , the outer periphery of the heat preservation box 1 is provided with a peripheral installation base shell 2, the inner side of the outer periphery installation base shell 2 is fixedly installed with a first inner fixed strip 3, and the outer side of the heat preservation box 1 is fixedly connected with a second locking flap 5. A second conductive contact groove 7 is provided on the second clamping flap 5; a first conductive contact groove 7 matched with the second conductive contact groove 7 on the second clamping flap 5 is provided on the first inner fixed strip 3. Conductive plug 8.

[0043] see figure 2 , Figure 5 , the outer side of the heat preservation box 1 is evenly provided with some convex columns 9 outside the box; The inner heat conduction rod 10 at the position; the outer surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com