Unsupported 3D printing method based on dynamic slicing algorithm

A 3D printing, unsupported technology, applied in the field of space 3D printing, can solve the problems of difficult to remove, difficult to print without support, etc., to avoid the post-processing process, reduce printing consumables and time, and improve flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in detail below according to the accompanying drawings and examples. The present example is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following Described embodiment.

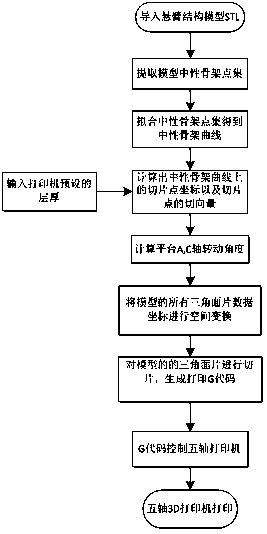

[0052] Such as figure 1 Shown, a kind of unsupported 3D printing method of dynamic slicing algorithm, comprises the following steps:

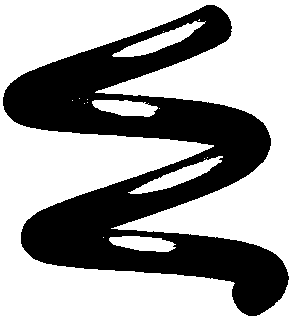

[0053] Step 1: In this example, Pro / E 5.0 software is used as the 3D modeling software, and the following figure 2 The model of the spiral hollow pipe is shown, and it is stored as an STL format file.

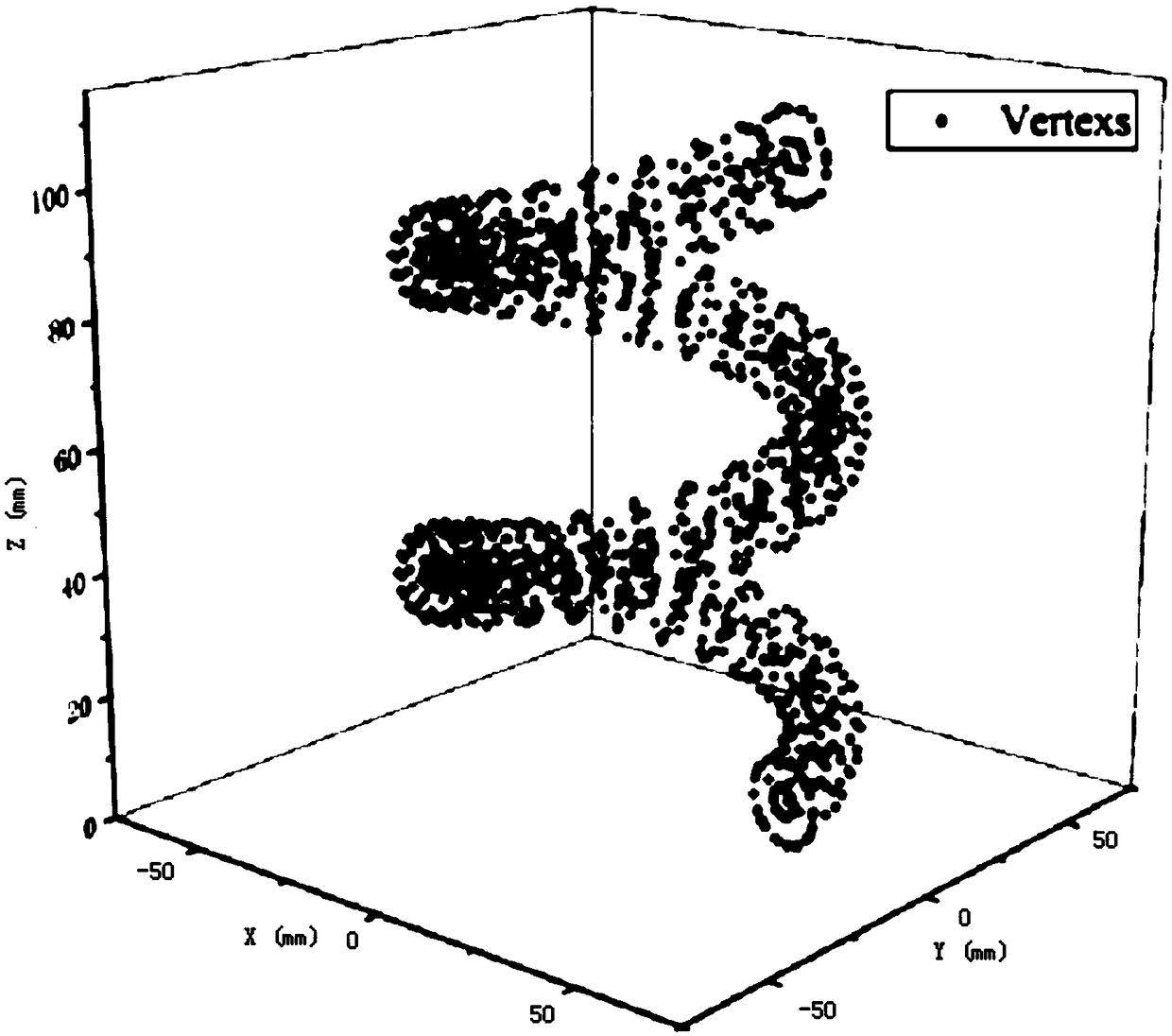

[0054] The second step: if image 3 As shown, the model is placed in the spatial rectangular coordinate system, and according to the characteristics of the five-axis linkage 3D printer, the A axis rotating around the X axis (the swing axis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com