Printer combining direct writing type printing and hot melting deposition type printing and printing method

A thermal fusion deposition, direct-write technology, applied in the field of additive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

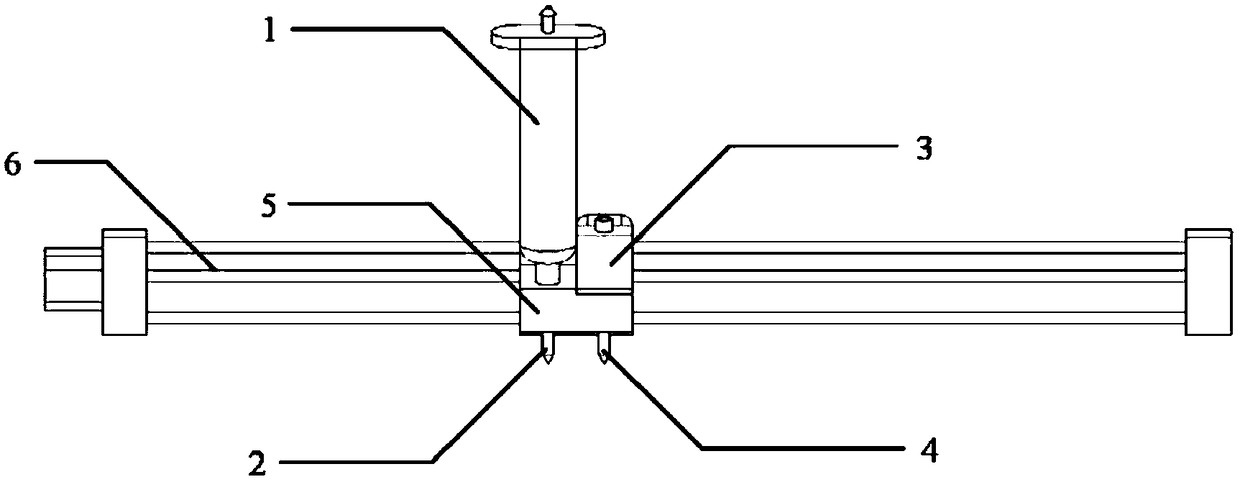

[0032] First build the feeding system of DIW direct writing 3D printer, including extrusion head, throat, feeding needle, air control box, air pump and electronic control board. The air control box is controlled by the firmware program in the electronic control board to change the air pressure in the feeding needle, and push the printing material in the feeding needle to flow into the throat and extrude from the extrusion head.

[0033] Then build FDM hot melt deposition is the 3D printer feeding system, including extrusion head, heating module, throat, feeding motor and electronic control board. According to the type of printing wire, the heating temperature is set through the electronic control board, that is, the feeding speed, and the printing wire is pushed into the melting chamber of the throat, and the wire is extruded from the extrusion head.

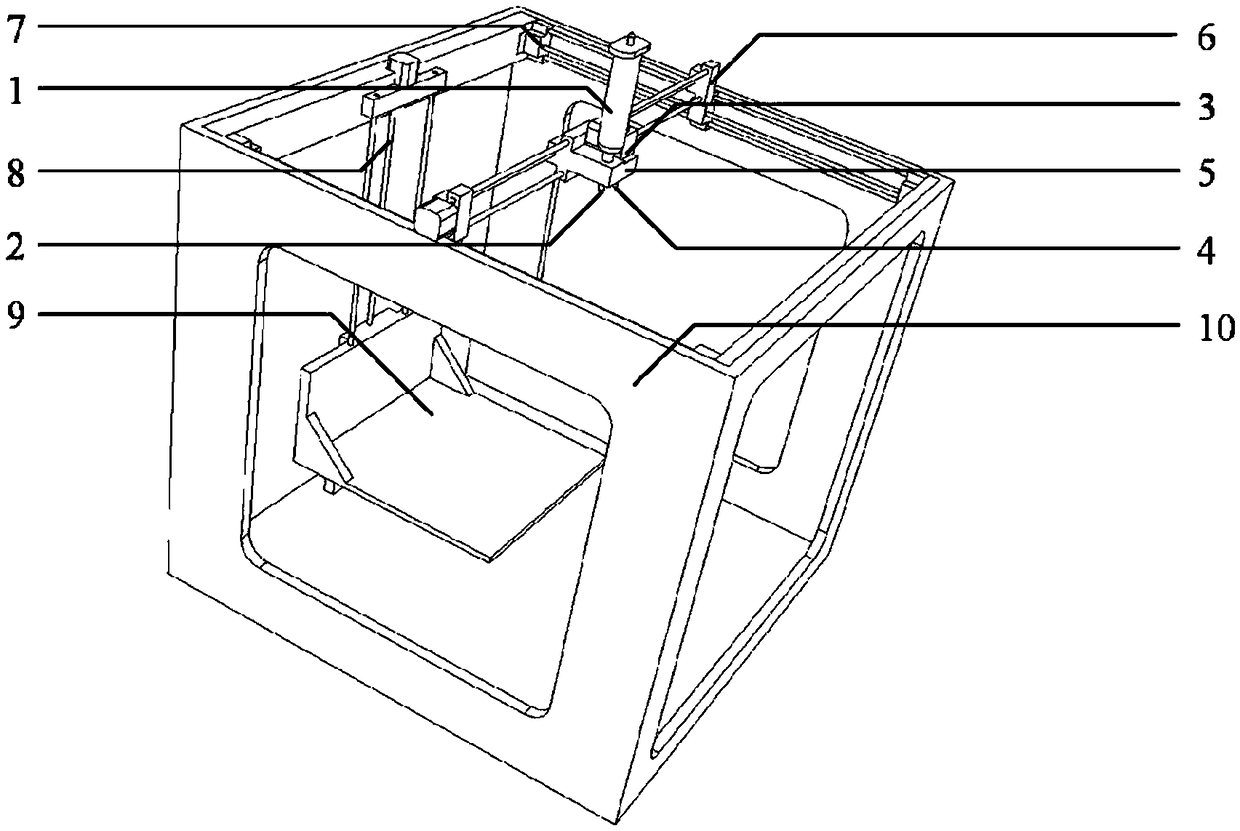

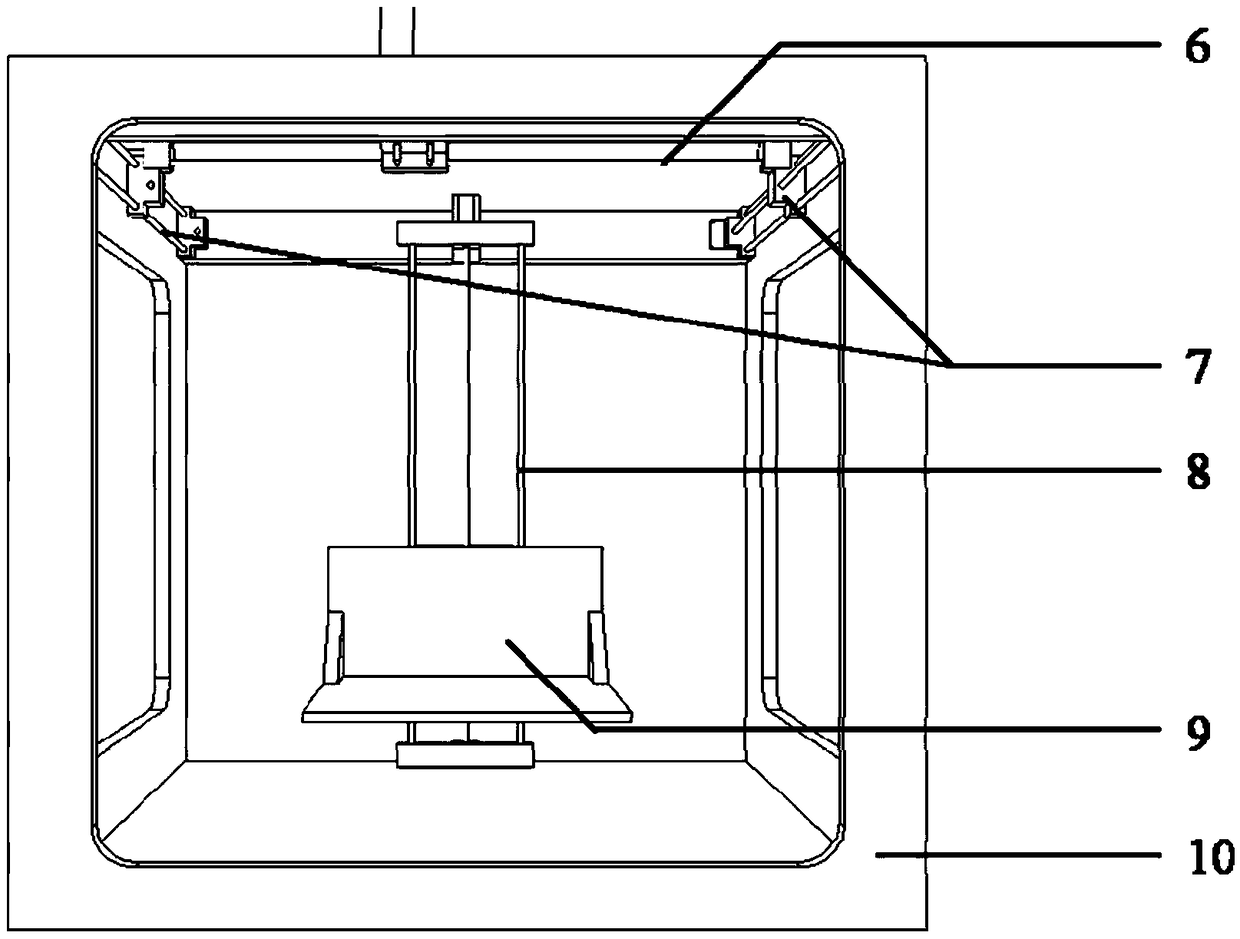

[0034] Finally, build the XYZ three-axis displacement platform, including the main control electronic control board, three-axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com