Injection molding machine

A technology of injection molding machine and injection head, which is applied in the field of injection molding machines, can solve problems such as low production efficiency and easy blockage of nozzles, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

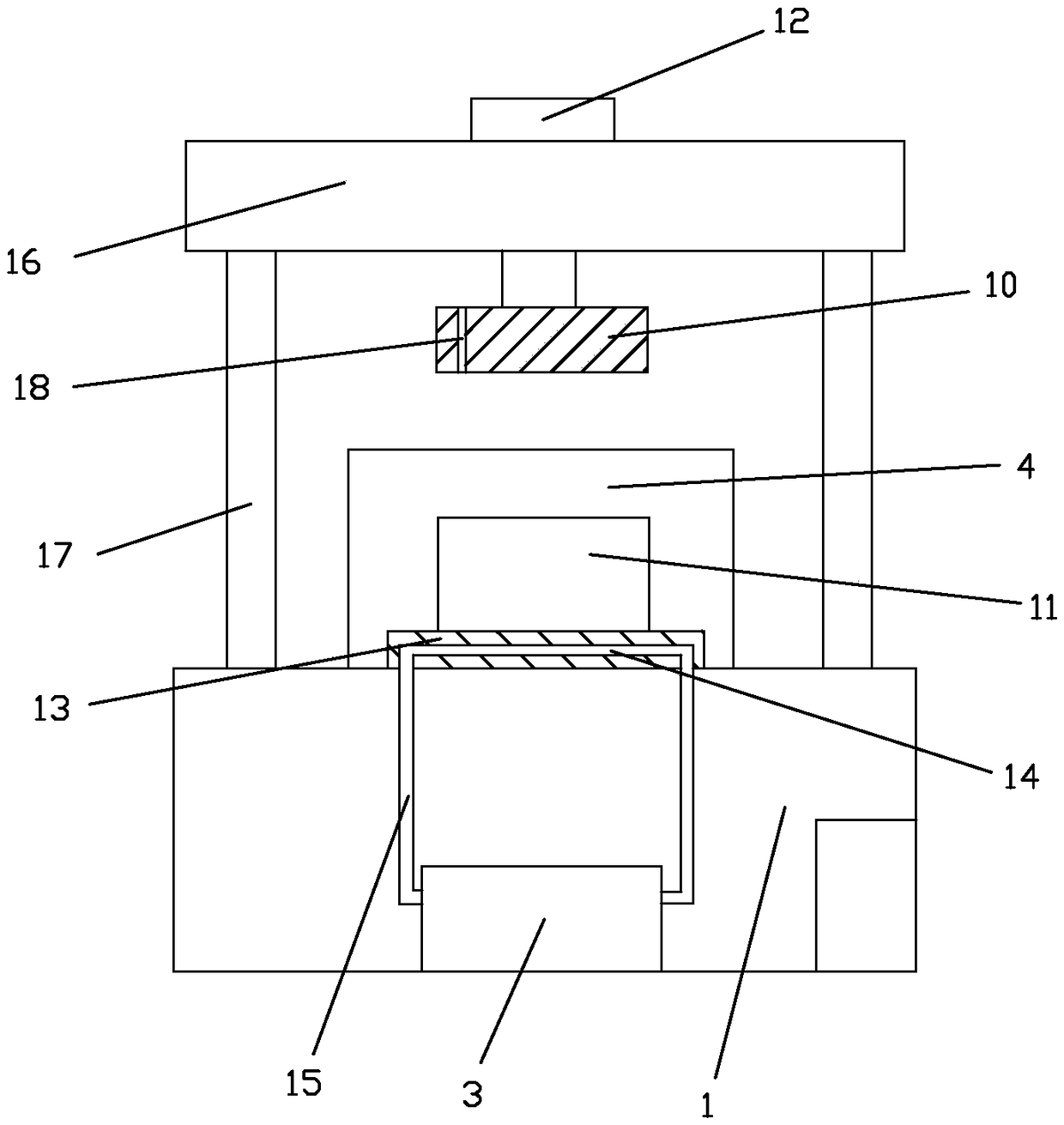

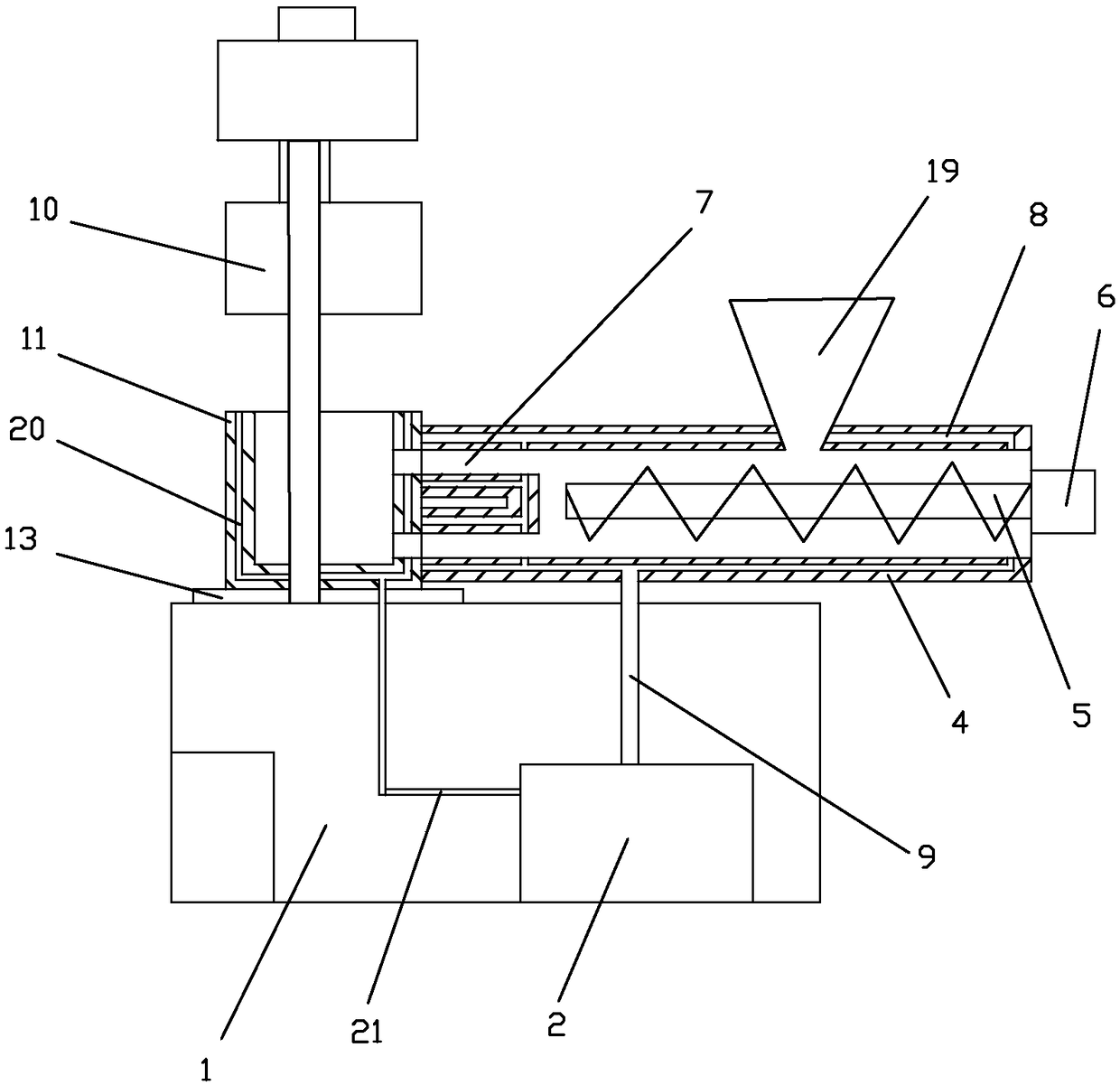

[0017] Such as figure 1 and figure 2 As shown, an injection molding machine includes a frame 1, an oil reservoir 2 for storing and heating heat transfer oil and a water reservoir 3 for storing cooling water are installed in the frame 1, and an injection molding mechanism is installed above the frame 1 And the clamping mechanism, the injection molding mechanism includes a heater 4 and a screw rod 5 for driving plastic discharge, the screw rod 5 is installed in the heater 4 and is connected with a servo motor 6 for driving the screw rod 5 to rotate along its own axis, and the heater 4 is provided with Two injection molding heads 7 for pouring plastic, the heater 4 and the inner wall of the injection molding head 7 are provided with a first cavity 8 for accommodating heat transfer oil, the first cavity 8 communicates with the oil reservoir 2 through an oil delivery pipeline 9, and is combined. The mold mechanism comprises an upper mold 10 and a lower mold 11 which cooperate wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com