Device and method for processing inclined surface through follow-up sealing liquid cutting-in type electrolytic milling machining

A technology of milling and beveling, which is applied in the direction of electric processing equipment, electrochemical processing equipment, accessory devices, etc., can solve the problems of processing disorder, aggravate stray corrosion in non-processing areas, etc., and achieve the effect of improving precision and reducing stray corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

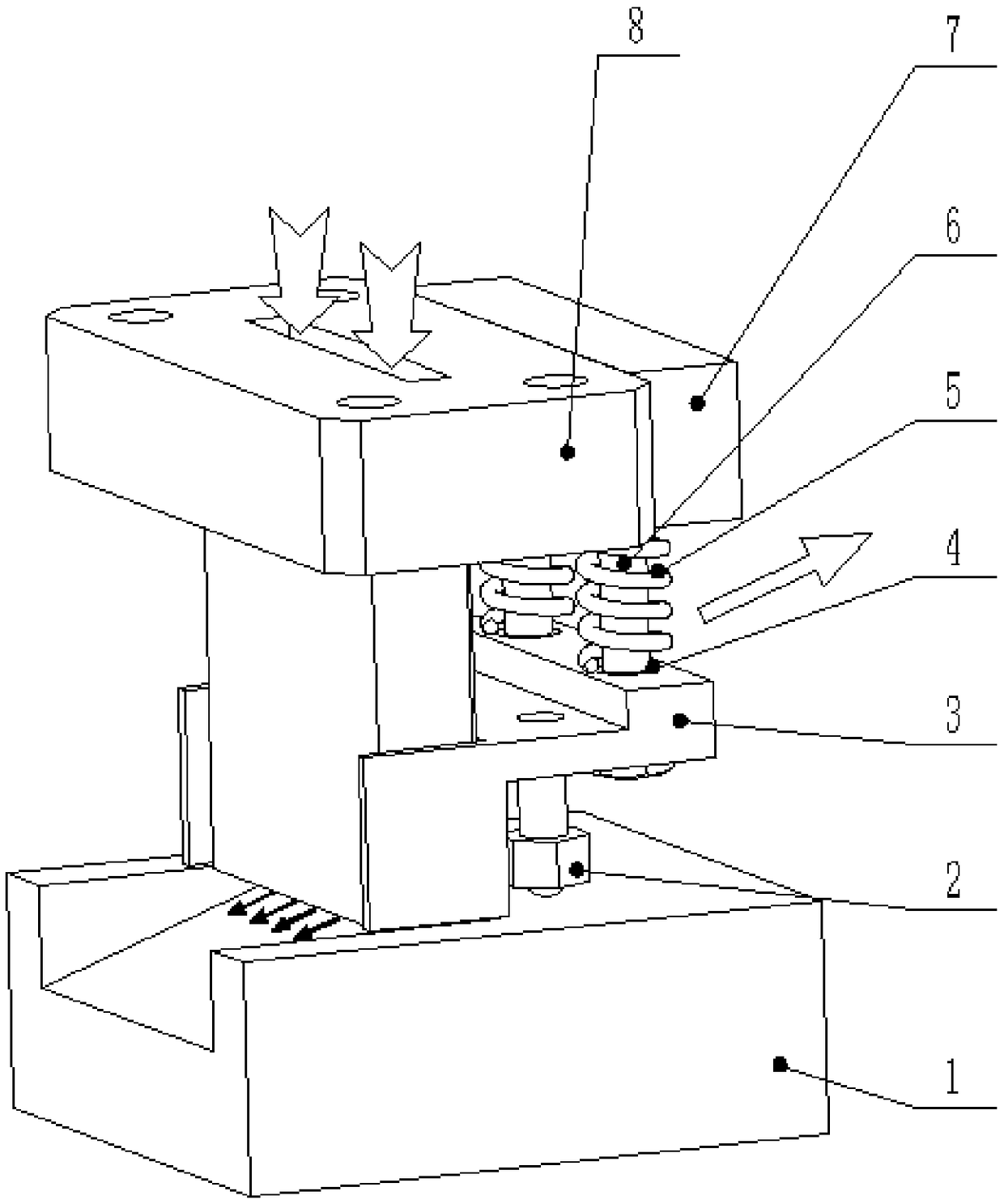

[0032] Such as figure 1 As shown, the present invention includes a tool cathode, an upper support plate, a guide rod, a spring, a linear bearing, a universal ball and a water blocking block, and can electrolytically process a slope of any angle on a square blank, thereby improving processing efficiency and processing stability .

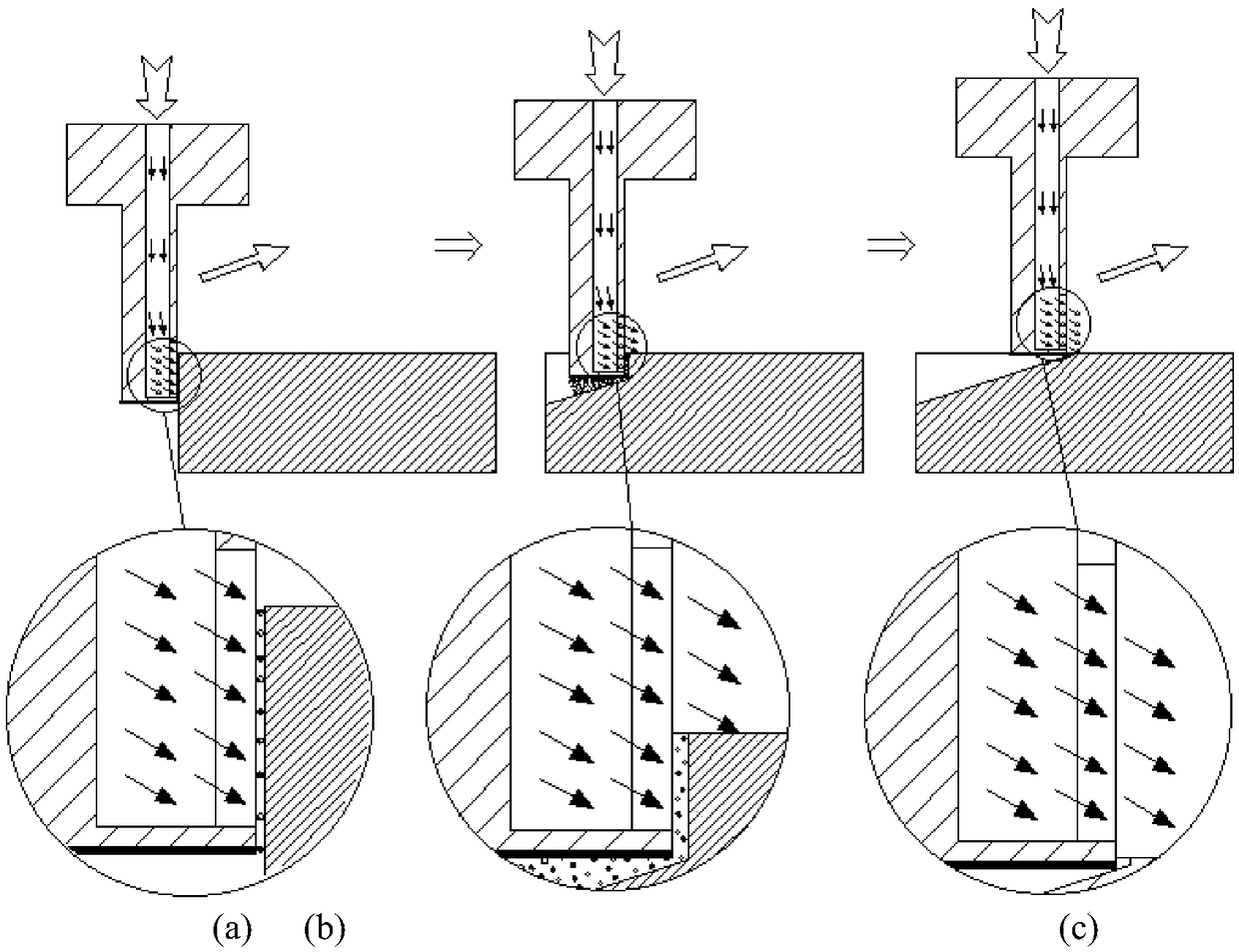

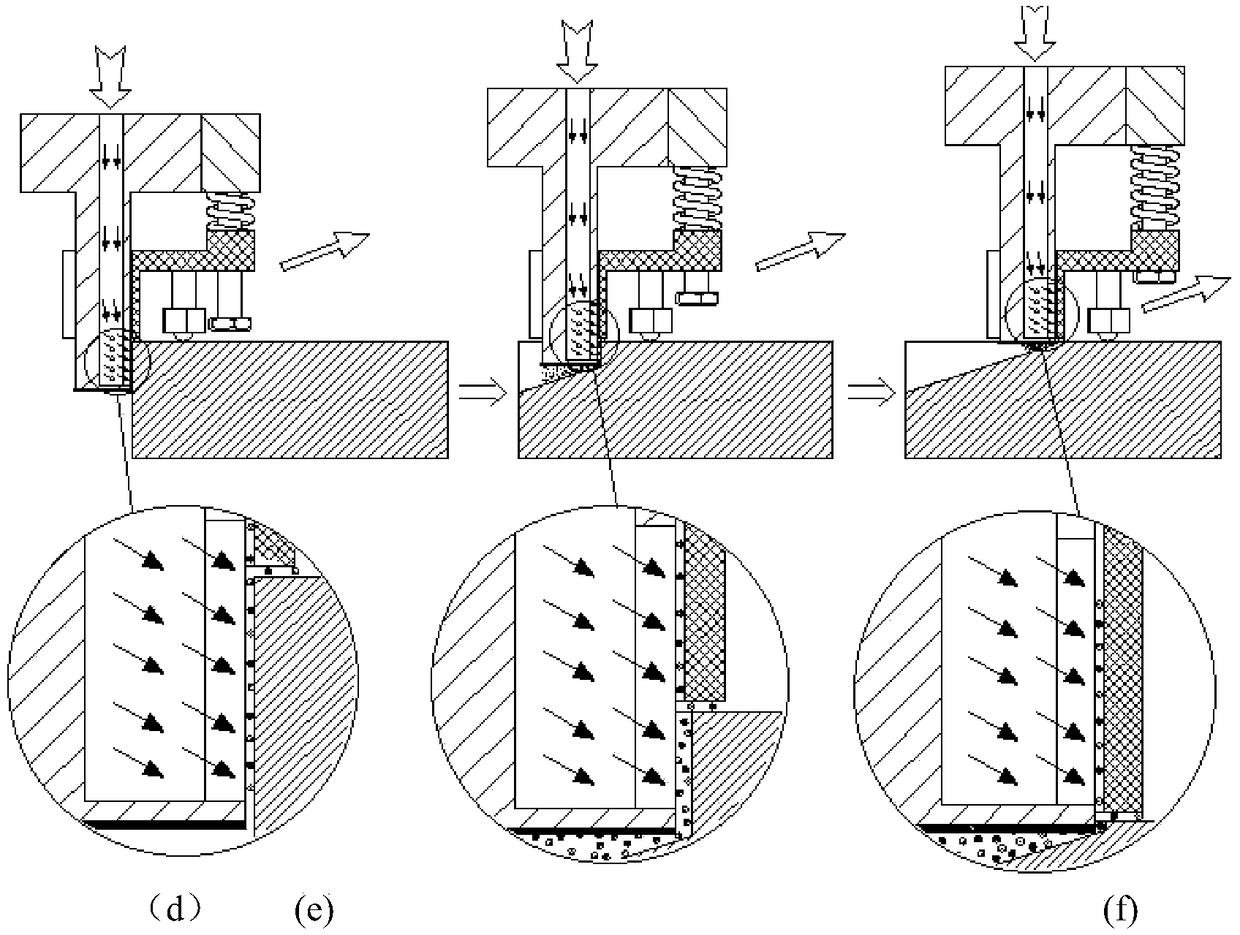

[0033] Such as Figure 4 As shown, the hollow cuboid structure inside the cathode of the tool has a row of narrow slits on the front opposite to the surface of the workpiece to be processed, which can evenly spray the electrolyte, and the left and right sides, bottom surface, and back are insulated to avoid stray corrosion. Such as Figure 5 As shown, from front to back, the water retaining block is a water retaining part surrounded by three sides, a middle plate-shaped connecting part and a rear block-shaped sliding part. combine figure 1 Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com