Hardware plate tension device

A technology of stretching device and metal plate, applied in the field of stretching device, can solve the problems of surface damage of metal plate, limitation of technical scheme, elimination of internal stress of metal plate, etc., so as to achieve the effect of improving reliability and eliminating internal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

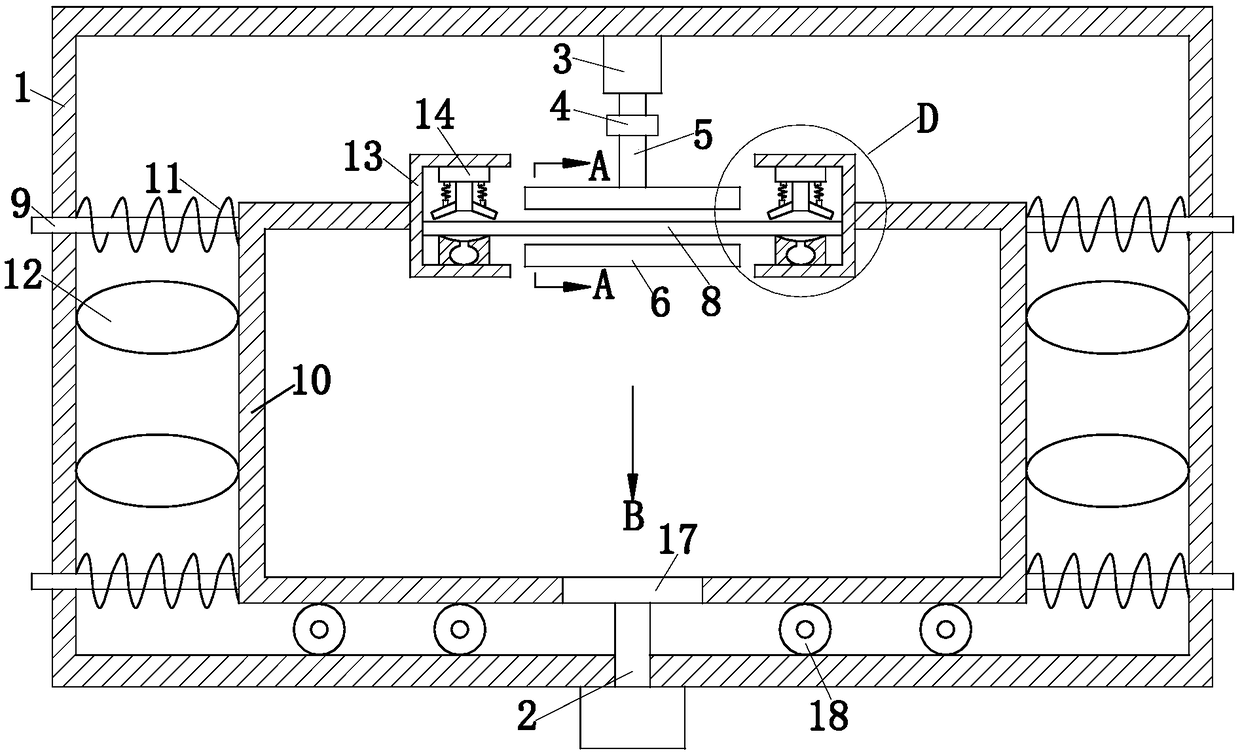

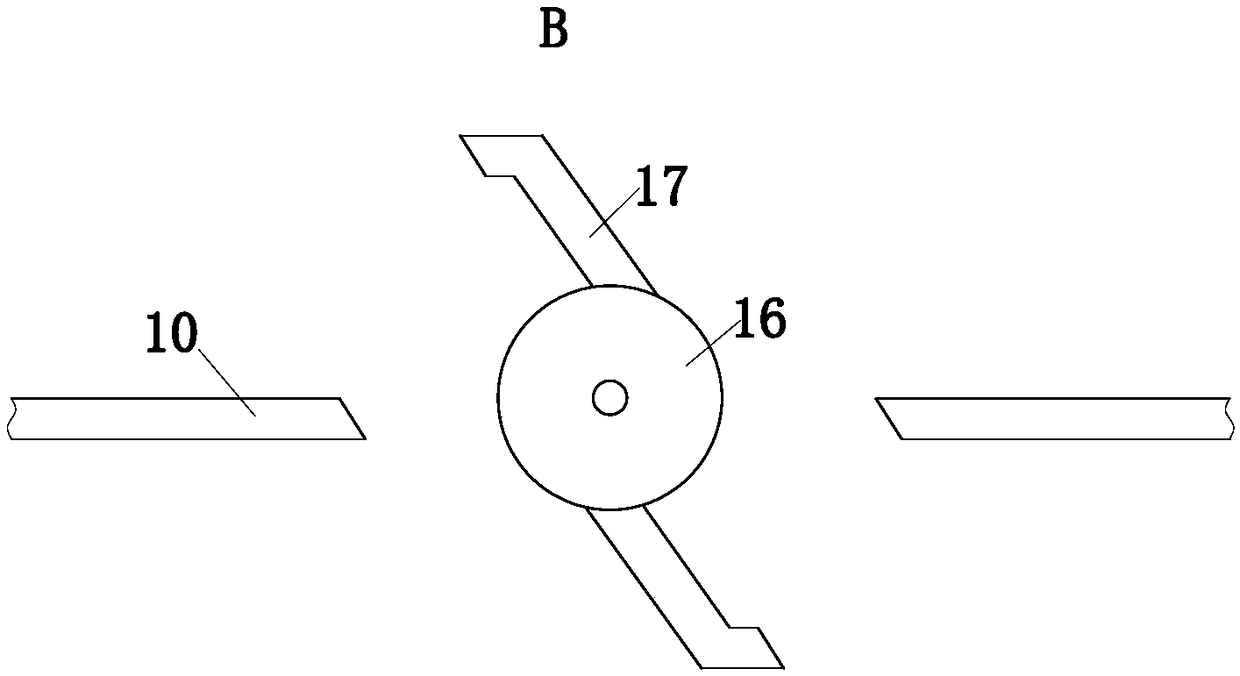

[0030] As an embodiment of the present invention, the inner side of the bottom of the empty box 1 is slidingly connected with the U-shaped pull plate 10 through the rotating shaft 18, and the rotating shaft 18 can reduce the friction between the U-shaped pull plate 10 and the empty box 1, which is beneficial to U-shaped Type pull plate 10 motions.

[0031] As an embodiment of the present invention, the gear teeth 17 of the runner 16 cooperate with the tapered surface on one side of the opening end of the U-shaped pull plate 10; The section of the gear teeth 17 can also be self-locked with one side of the U-shaped pull plate 10 to prevent the U-shaped pull plate 10 from rebounding when stretching the metal plate 8, which affects the stretching effect of the hardware plate 8.

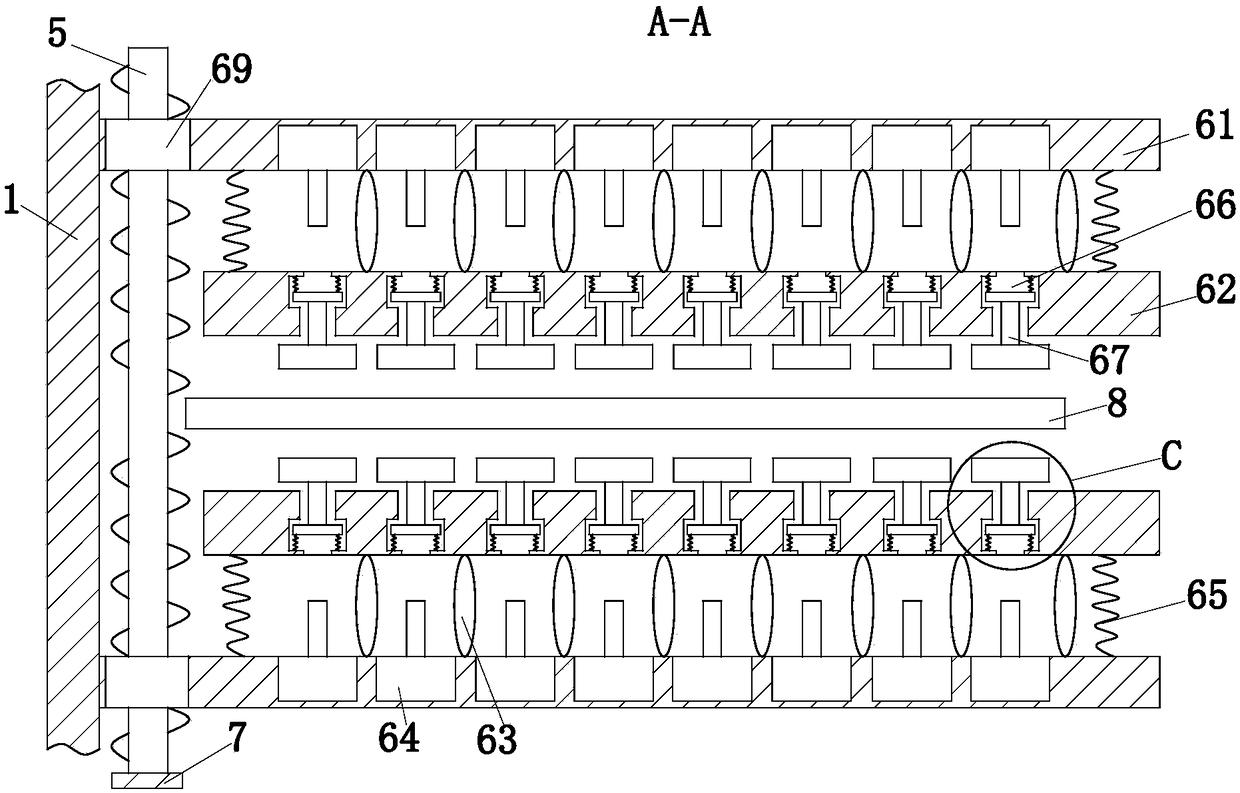

[0032] As an embodiment of the present invention, the two sides of the output end of the No. 2 cylinder 14 are symmetrically provided with a briquetting block 141 with the No. 2 cylinder 14; The side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com