A deep blind hole cleaning method for mechanical production maintenance

A cleaning method and technology of deep blind holes, applied in cleaning methods and tools, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as inability to work on-site parts, poor cleanliness uniformity, and high cost of evaporative cleaning. Achieve the effect of flexible use, simple structure and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

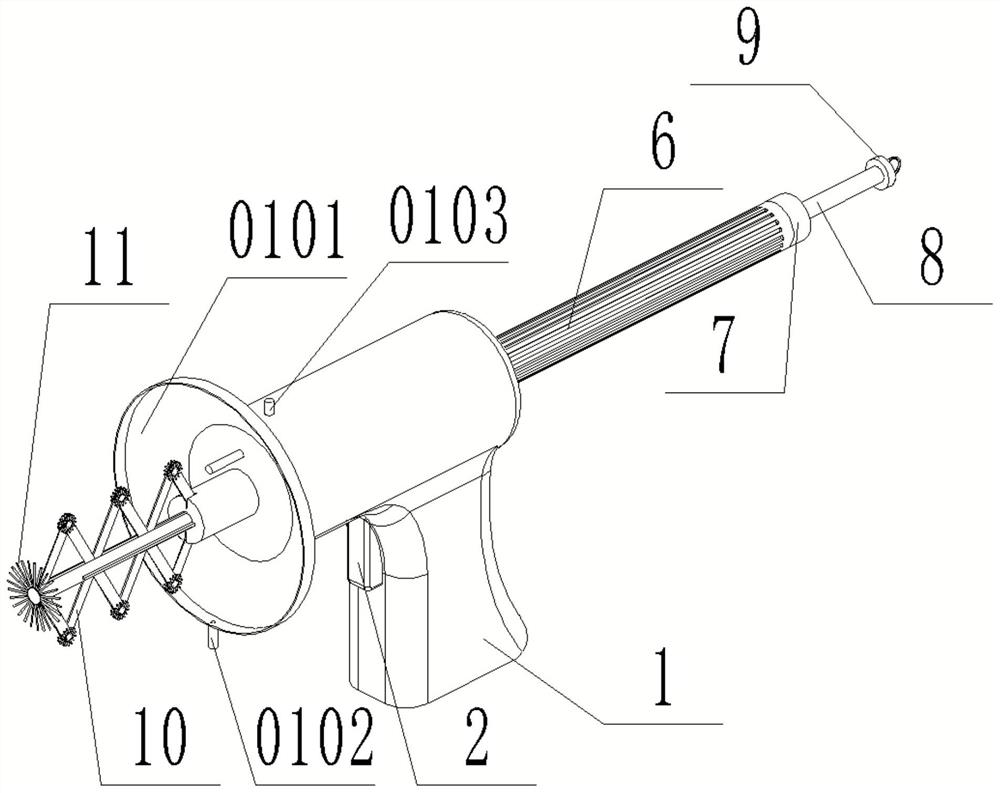

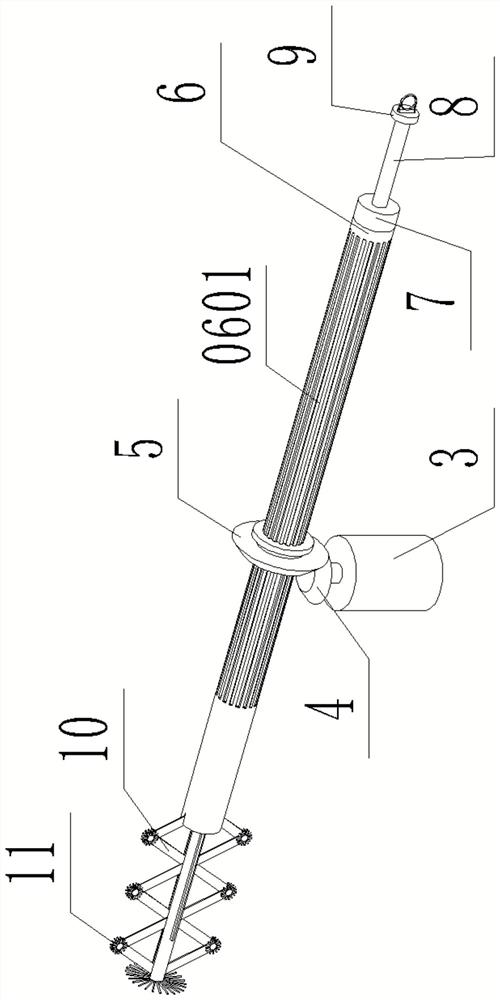

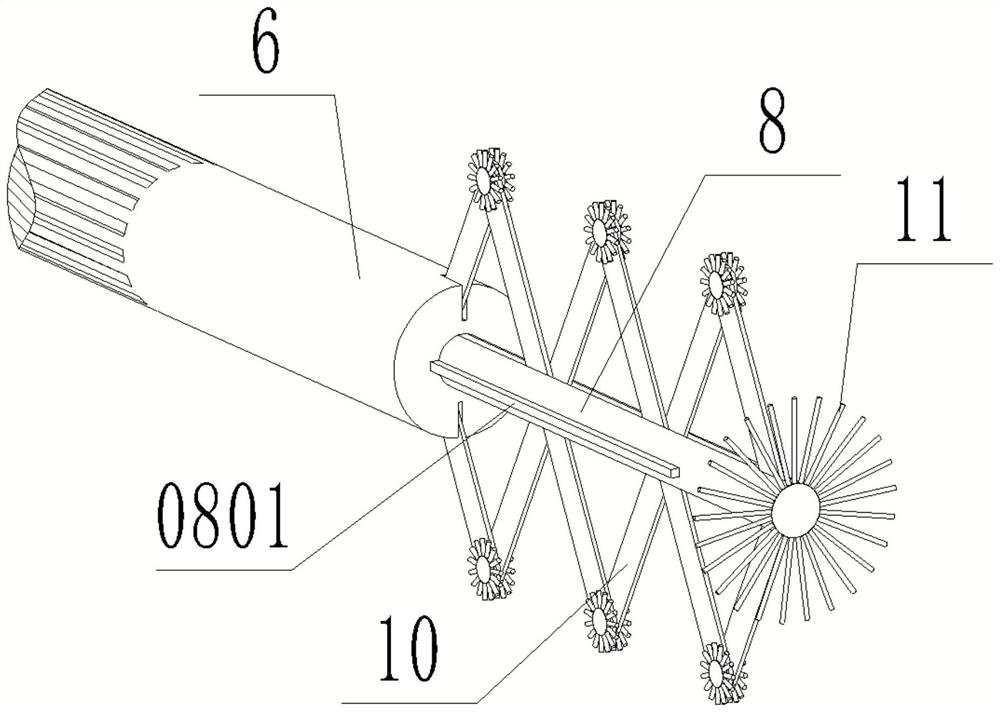

[0039] The invention provides a deep blind hole cleaning method for mechanical production and maintenance. The cleaning method is realized based on a deep blind hole cleaning device. The cleaning method includes a large-diameter deep blind-hole cleaning step and a small-diameter deep blind hole cleaning step;

[0040] as attached figure 1 to attach Figure 8Shown: The deep blind hole cleaning device includes: gun body 1, cleaning agent collecting cover 0101, cleaning agent return pipe 0102, cleaning liquid adding pipe 0103, manual button 2, motor 3, driving bevel gear 4, driven bevel gear 5 , diameter adjustment rod 6, spline teeth 0601, diameter adjustment wheel 7, pull rod 8, feather key 0801, T-shaped chute 0802, hand shaft 9, connecting rod 10, cleaning brush 11 and hinge shaft 12; gun body A group of motors 3 is fixedly connected to the handle part of 1; a group of driving bevel gears 4 is fixedly connected coaxially on the rotating shaft of the motor 3; a group of drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com