Production device and process of PPS filter bag with combined removal function of combined pollutants

A technology of combined removal and production equipment, applied in filtration separation, dispersed particle filtration, dispersed particle separation, etc., can solve the problem that it cannot adapt to the PPS bag production market, fails to propose the removal function of PPS bags, and cannot fundamentally reform PPS problems such as the cloth bag market, to achieve the effect of high active mercury oxidation efficiency, expansion of the domestic application market, cost savings and renovation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

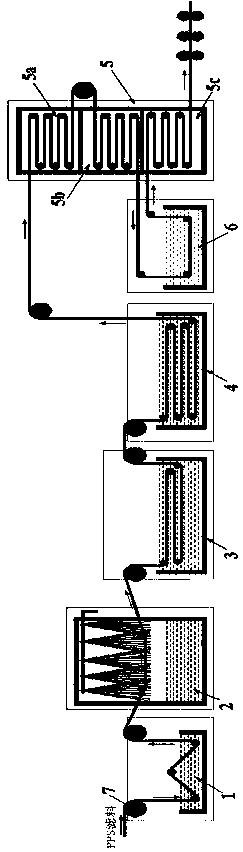

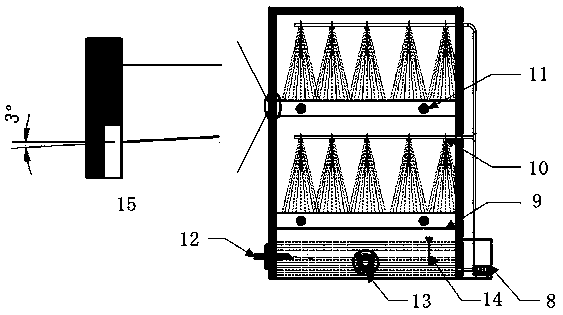

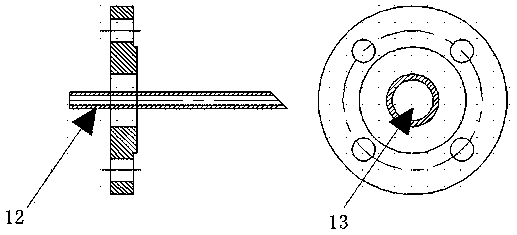

[0036]Embodiment 1: a kind of production device of the PPS filter bag of combined pollutant removal function, described production device comprises nitric acid solution pool 1, circulating spray tower 2, sodium lauryl sulfate solution pool 3, active group Salt solution pool 4, three-stage drying oven 5, PTFE solution pool 6 and power mechanism; the three-stage drying oven 5 is composed of a low-temperature drying oven 5a, a high-temperature drying oven 5b and a medium-temperature drying oven 5c.

[0037] The nitric acid solution pool 1 is provided with a PPS filter material inlet, and the medium temperature drying box 5c is provided with a PPS filter material outlet; the PPS filter material inlet is connected to the nitric acid solution successively through a pipeline and a power mechanism Pool 1, circulating spray tower 2, sodium lauryl sulfate solution pool 3, active component salt solution pool 4, low temperature drying oven 5a, high temperature drying oven 5b, PTFE solution...

Embodiment 2

[0052] Example 2: The production process of a PPS filter bag with combined pollutant removal function. The impregnation process configures the concentration of the active component salt solution to be 0.1kg / L. The filter material passes through the solution pool through 6 strokes. The remaining preparation steps and performance The test was carried out according to Example 1, and the experimental results are shown in Table 1.

Embodiment 3

[0053] Example 3: The production process of a PPS filter bag with combined pollutant removal function. The impregnation process configures the concentration of the active component salt solution to be 0.25kg / L. The filter material passes through the solution pool through 6 strokes. The remaining preparation steps and performance The test was carried out according to Example 1, and the experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com