A bone needle structure for external fixation

An external fixation and bone acupuncture technology, applied in the direction of fixator, puncture needle, trocar, etc., can solve the problems of affecting the recovery speed of the patient's wound healing, secondary injury of the patient's wound, poor affinity, etc., to facilitate rapid healing , the structure is simple, the effect of promoting the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

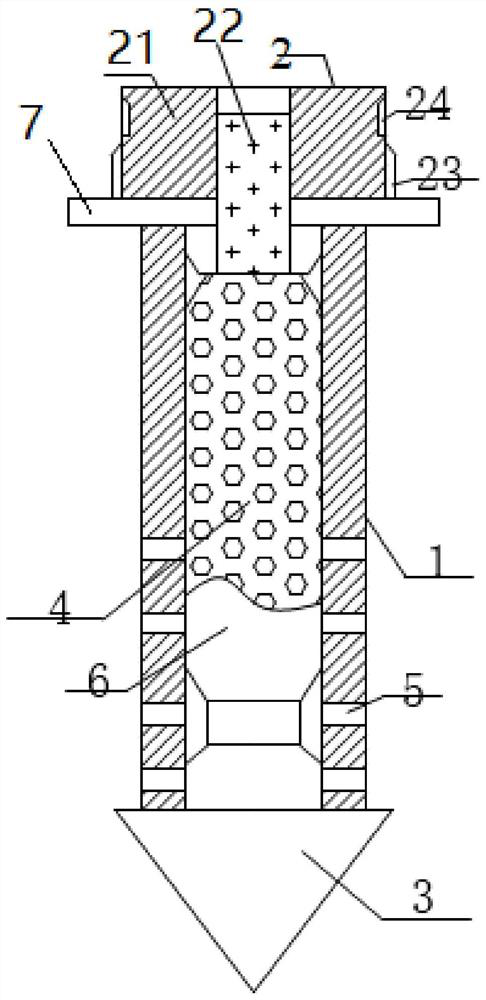

[0015] like figure 1 The bone needle structure for external fixation includes a metal needle body 1, a tail cap 2, a poly-L-lactic acid needle head 3 and a poly-lactic acid inner core 4. The metal needle body 1 is a hollow tubular structure, and the inner surfaces of the front end and the end Connecting threads are evenly distributed on the upper part, a number of through holes 5 are evenly distributed on the side wall of the front half of the metal needle body 1, and the axes of the through holes 5 are perpendicular to the axis of the metal needle body 1, the left-handed polylactic acid needle 3 is a conical structure, and the rear end surface Embedded in the front surface of the metal needle body 1 and connected with the metal needle body 1 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com