Biologically-fermented aquatic compound feed

A technology of compound feed and bio-fermentation, which is applied in the direction of animal feed, animal feed, molding or processing of animal feed, etc., can solve the problems of reducing breeding income, reducing fish resistance, and loss of farmers, so as to achieve good body color and reduce Effect of reducing dust and water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

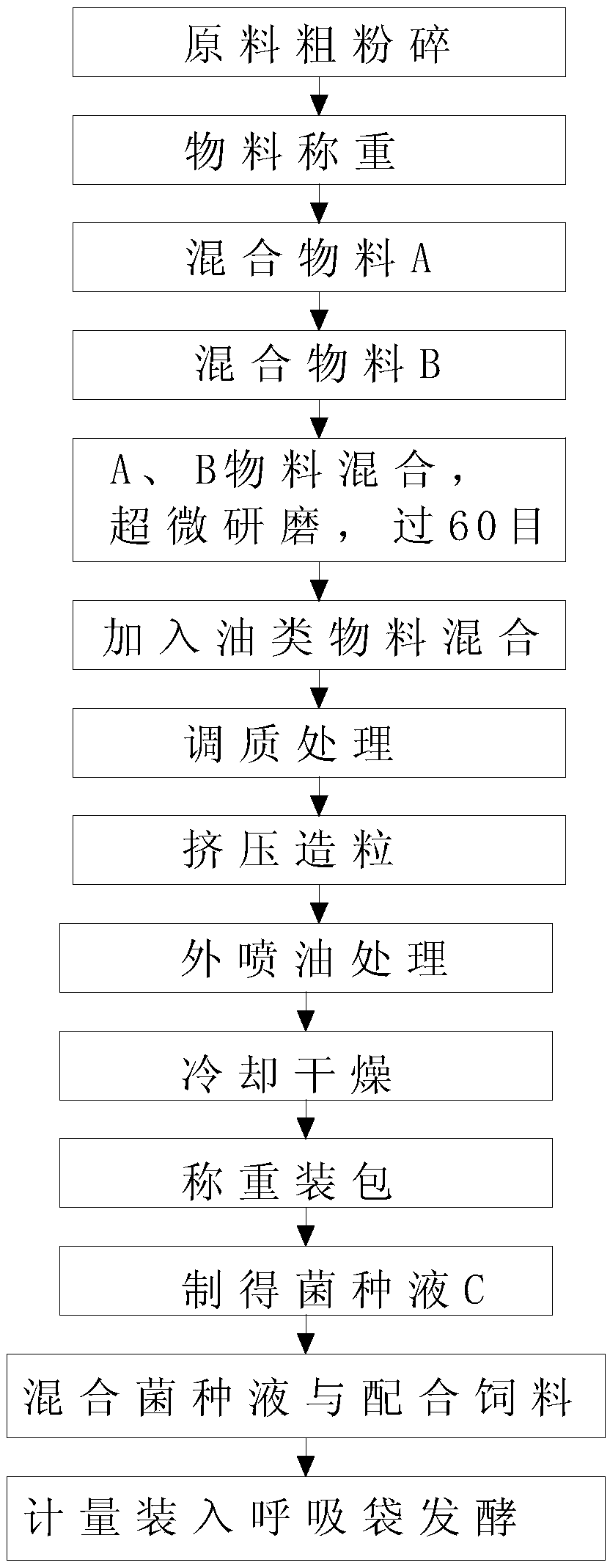

Method used

Image

Examples

Embodiment 1

[0036] 1. Use a 2.0 sieve to coarsely pulverize all raw materials and set aside;

[0037] 2. Weigh each material separately according to the weight ratio;

[0038] 3. Mix 20 parts of peeled and expanded soybean meal, 10 parts of rapeseed meal, 10 parts of cotton meal, 13 parts of wheat, 5 parts of imported fish meal, 3 parts of chicken meal, and 2 parts of calcium dihydrogen phosphate to obtain the mixed material A, and set aside;

[0039] 4. Mix 0.1 part of slow-release coated methionine, 0.2 part of lysine, 0.2 part of choline, and 1 part of aquatic product premix to obtain the mixture B;

[0040] 5. After mixing the mixed material A and the mixed material B, carry out ultrafine pulverization, and 80% pass through a 60-mesh sieve;

[0041] 6. When the superfine pulverized material enters the mixer for stirring, add 0.5 to 1 part of soybean lecithin oil and 2 to 5 parts of soybean oil in sequence, and set aside;

[0042] 7. Use 75kg / ton pipeline saturated steam, two layers ...

Embodiment 2

[0050] 1. Use a 2.0 sieve to coarsely pulverize all raw materials and set aside;

[0051] 2. Weigh each material separately according to the weight ratio;

[0052] 3. Mix 22 parts of peeled and puffed soybean meal, 13 parts of rapeseed meal, 8 parts of cotton meal, 10 parts of wheat, 7 parts of imported fish meal, 5 parts of chicken meal, and 2.2 parts of calcium dihydrogen phosphate to obtain the mixed material A and set aside;

[0053] 4. Mix 0.15 parts of sustained-release coated methionine, 0.25 parts of lysine, 0.25 parts of choline, and 1.5 parts of aquatic product premix to obtain mixture B;

[0054] 5. After mixing the mixed material A and the mixed material B, carry out ultrafine pulverization, and 80% pass through a 60-mesh sieve;

[0055] 6. When the superfine pulverized material enters the mixer for stirring, add 0.8 parts of soybean lecithin oil and 3 parts of soybean oil in sequence, and set aside;

[0056] 7. Use 75kg / ton pipeline saturated steam, two layers o...

Embodiment 3

[0064] 1. Use a 2.0 sieve to coarsely pulverize all raw materials and set aside;

[0065] 2. Weigh each material separately according to the weight ratio;

[0066] 3. Mix 24 parts of peeled and expanded soybean meal, 15 parts of rapeseed meal, 6 parts of cotton meal, 8 parts of wheat, 8 parts of imported fish meal, 6 parts of chicken meal, and 2.4 parts of calcium dihydrogen phosphate to obtain the mixed material A, which is set aside;

[0067] 4. Mix 0.2 parts of sustained-release coated methionine, 0.3 parts of lysine, 0.3 parts of choline, and 2 parts of aquatic product premix to obtain a mixture B;

[0068] 5. After mixing the mixed material A and the mixed material B, carry out ultrafine pulverization, and 80% pass through a 60-mesh sieve;

[0069] 6. When the superfine pulverized material enters the mixer for stirring, add 1 part of soybean lecithin oil and 5 parts of soybean oil in sequence, and set aside;

[0070] 7. Use 75kg / ton pipeline saturated steam, two layers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com