A filter with multiple filtering functions

A filter and multi-filter technology, applied to the circuit layout, electrical components, chassis/cabinet/drawer parts and other directions on the support structure, which can solve the problem of error-prone wiring, large occupancy, and messy wiring, etc. problems, to achieve the effect of convenient movement and subsequent installation, reducing the occupied volume and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

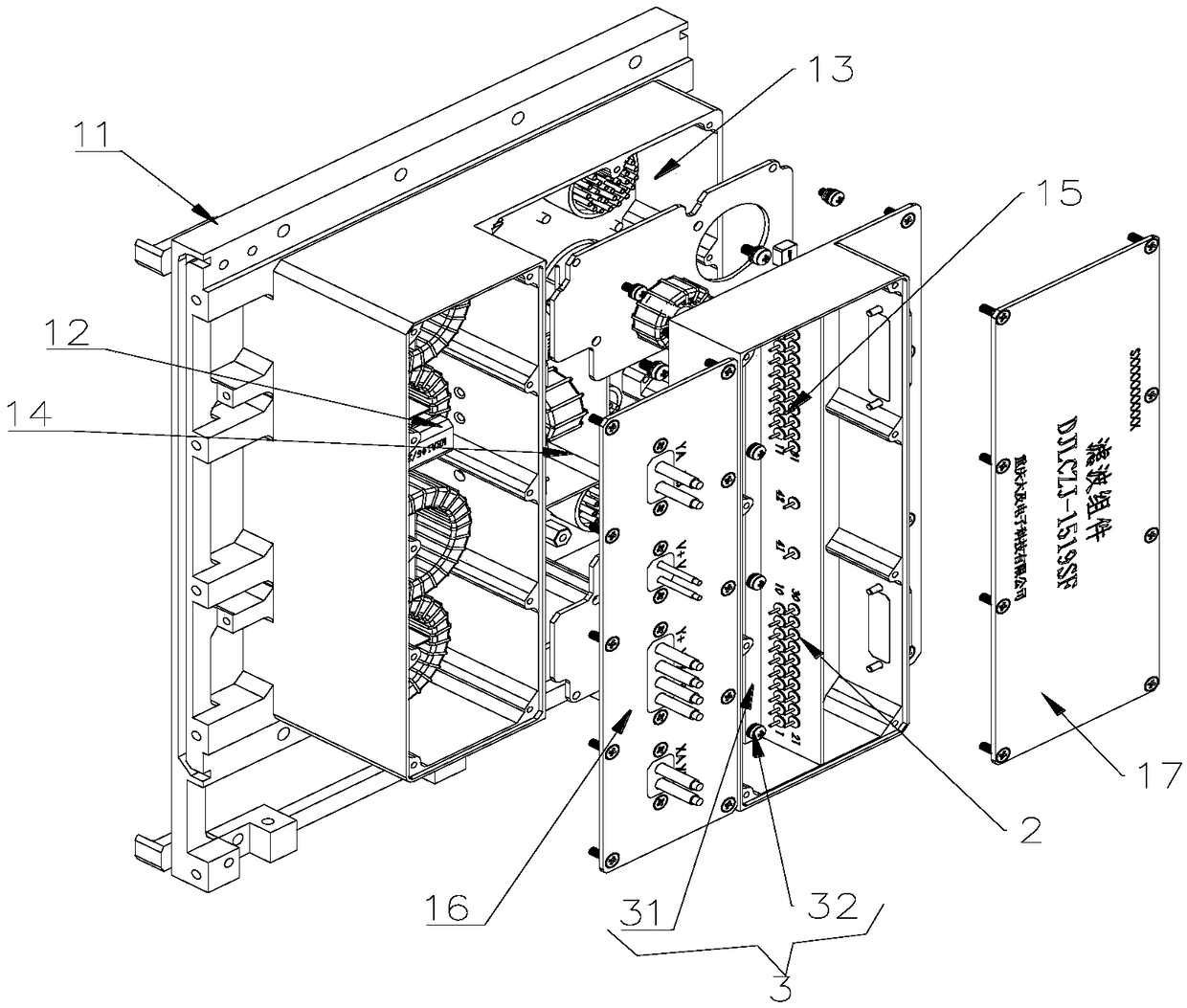

[0025] Such as Figure 1 to Figure 5 As shown, the present invention proposes a filter with multiple filtering functions, including: a main power supply filter module, a motor power supply filter module, a motor output PWM power supply filter module, a bus signal filter module, a serial port signal filter module and a chassis. The main power filter module for filtering the main power supply, the motor power supply filter module for filtering the motor power supply, the motor output PWM power filter module for filtering the motor output PWM power, and the A bus signal filtering module for filtering the bus signal and a serial port signal filtering module for filtering the serial port signal.

[0026] In order to avoid mutual coupling caused by different signals generated by each module in the chassis, the chassis includes: a panel 11, a first installation groove body 12, a second installation groove body 13, a third installation groove body 14, a fourth installation groove body...

Embodiment 2

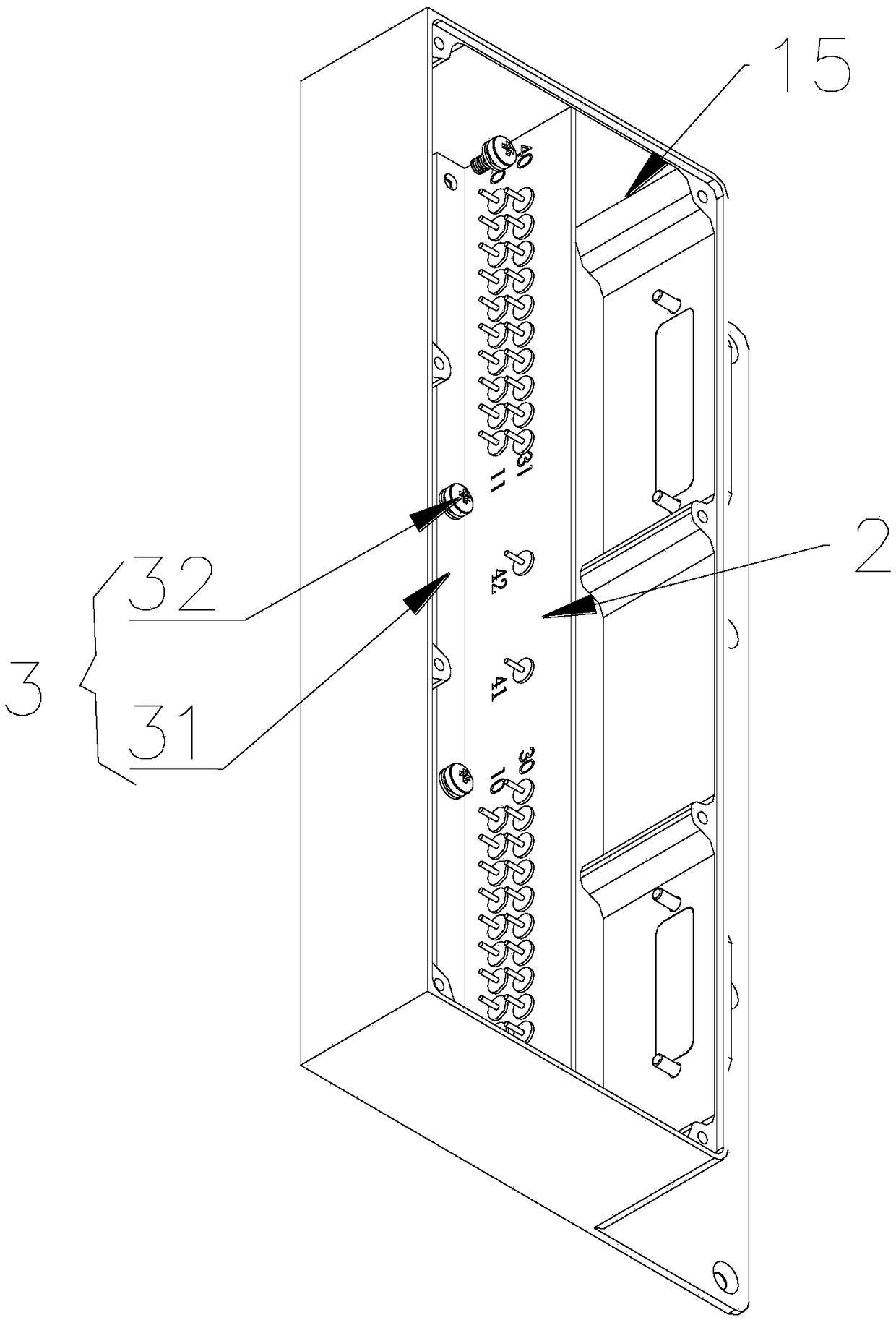

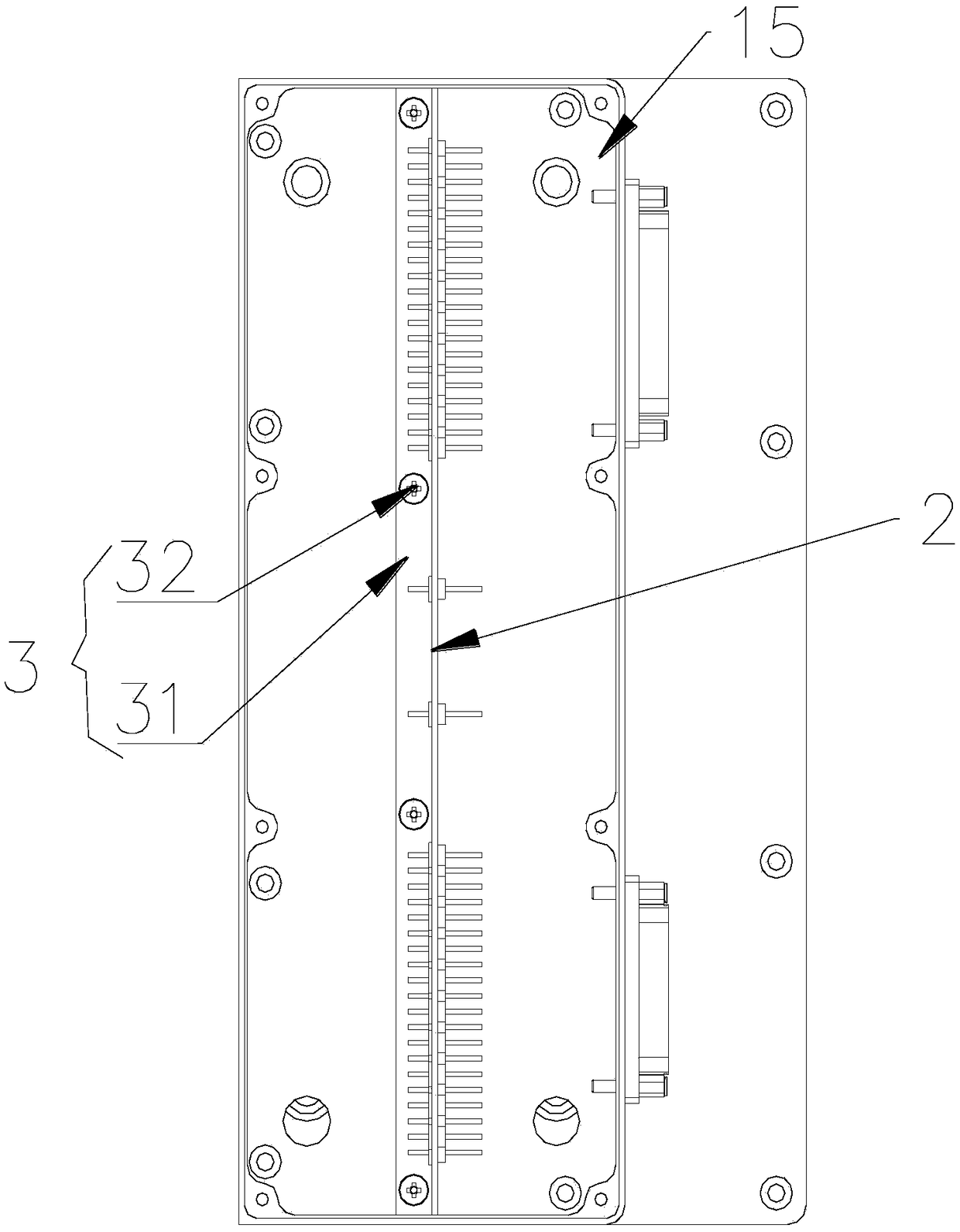

[0037] Such as Figure 6 as well as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that in Embodiment 1, when the ground plate 2 is connected with the feed-through capacitor, the mounting plate 31 is not easy to connect with the ground plate 2, and the feed-through capacitor is easily damaged during connection, so In this embodiment, on the basis of embodiment 1, only the first connecting component 3 is improved.

[0038] In order to avoid damage to the grounding plate 2, a first connection assembly 3 is installed at both ends of the grounding plate 2;

[0039]Each first connection assembly 3 includes: a mounting bracket 31', a first screw rod 32', a moving plate 33', a first spring 34', two vertical rods 35', two first wedges 36', two second Wedge 37', two guide cylinders 38', two guide rods 39' and two second springs 30', mounting frame 31' stand on the fourth mounting groove body 15 inner wall, mounting frame 31' is n-shaped, mounting frame...

Embodiment 3

[0042] Such as Figure 8 to Figure 11 As shown, the difference between this embodiment and Embodiment 1 is only: since the installation of the first installation ring 51 in Embodiment 1 also requires the installation of the connection plate 50, the connection between the connection plate 50 and the first cover plate 16 requires multiple screws, while Installing the first mounting ring 51 also requires multiple screws, and the screws need to be rotated multiple times to press the first mounting ring 51 on the first cover plate 16, resulting in difficult operation. In order to avoid the above problems, the present embodiment On the basis of 1, only the second connection assembly 5 is improved.

[0043] In order to realize the installation of the first cover plate 16 and the connecting head 4 only by rotating the rotating rod 542 less than one turn, the connecting head 4 is located on the side of the first cover plate 16 away from the first installation groove body 12, the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com