Large-section, high drop high-voltage cable line high point jointless continuous laying method

A high-voltage cable and high-drop technology, which is applied in the direction of cable laying equipment, cable installation, and cable installation devices, can solve problems such as high construction costs, hidden dangers in operation, and difficult operation and maintenance, and achieve the elimination of hidden safety hazards, shortening the construction period, and Effect of improving power supply reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

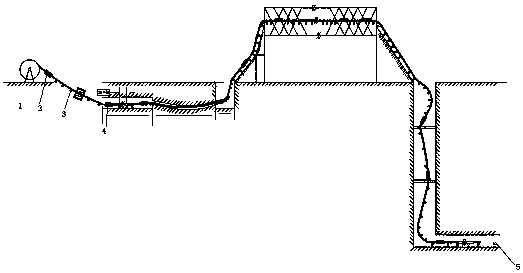

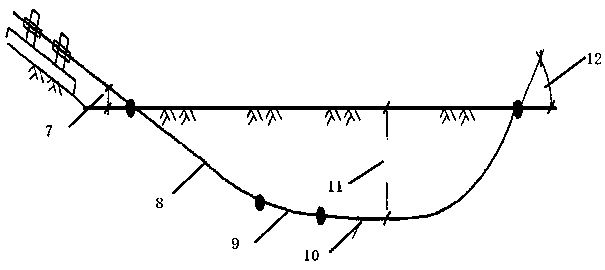

[0045] The following is a further description of the high-voltage, large-section, and high-drop cable line high-point non-joint laying method of the present invention in conjunction with the accompanying drawings.

[0046] See attached figure 2 , the non-joint continuous laying method includes the following steps:

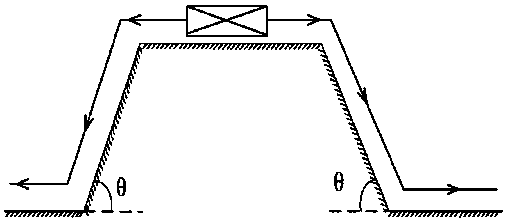

[0047] Step (1), determine the direction of continuous laying of large-section, high-drop high-voltage cable lines, because figure 2 The cable laying channel shown in is a complicated and high-drop cable channel including culverts, non-excavation pipe sections, narrow working wells, cable bridges, and cable caissons. The overall height of the side channel is higher than that on the right side, that is, the drop on the left side is small, and the drop on the right side is large. According to this construction method, the direction of continuous laying of high-voltage cable lines is determined to be from left to right, that is, along the "ji"-shaped drop The smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com