Cable laying device

A cable laying and cable reel technology, which is applied in the directions of cable laying equipment, transportation and packaging, thin material handling, etc., can solve the problems of cable changing from the guide groove, cable hanging on foreign objects, loss, etc., so as to reduce labor intensity and The effect of small friction and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

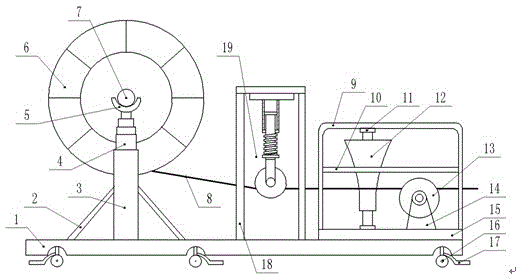

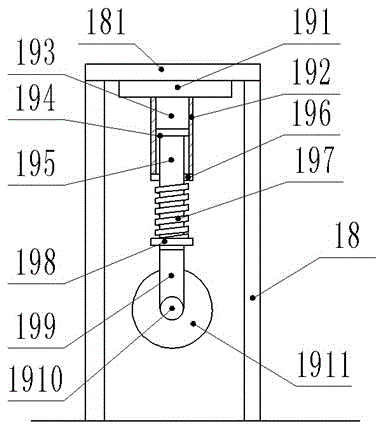

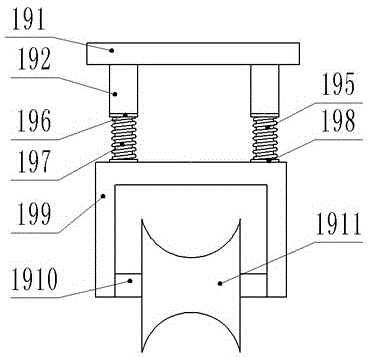

[0017] see Figure 1-4 , a cable laying device, comprising a base 1, a cable reel 6, a cable 8, a fixed frame 9, a guide bracket 18 and a third pulley 12; both sides below the base 1 are equipped with three sets of universal wheels 16, Brake pads 17 are provided on the wheel 16, and the brake pads 17 can limit the movement of the universal wheel 16. Two support columns 3 are symmetrically arranged above the left end of the base 1, and the outer walls of the support column 3 are fixed with supports. Frame 2, the support frame 2 makes the support column 3 more stable, the upper end of the support column 3 is fixed with a hydraulic jack 4, and the top of the hydraulic jack 4 is fixed with a support groove 5, and the support groove 5 is arc-shaped. A rotating shaft 7 is erected between the 5, wherein the cable reel 6 is set in the support groove 5 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com