A method for constructing seed tree effect of high specific surface carbon fiber mat and application thereof

A carbon fiber felt, high specific surface technology, applied in the construction method of planting effect and its application in vanadium batteries, can solve the problem of engineering promotion without vanadium batteries, providing economic benefits, low electrochemical activity and surface area, no modification It can solve the problems of vanadium batteries and other problems, and achieve the effects of easy engineering preparation, improved electrochemical surface area and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this example, graphene oxide is dispersed in a Nafion (perfluorosulfonic acid) / ethanol solution with a weight concentration of 0.02%, and the concentration is 2 mg·mL -1 A dispersion of graphene oxide; then soak the polyacrylonitrile graphite felt in the dispersion, put it into an oven for drying after the absorption is complete, the temperature of the oven is 60°C, and the drying time is 6h; Graphite felt in N 2 The carbonization treatment is carried out in the atmosphere, the carbonization temperature is 1000°C, and the carbonization time is 3h. Finally, a carbon fiber felt composite electrode with a high specific surface area modified by nanometer graphene oxide can be obtained.

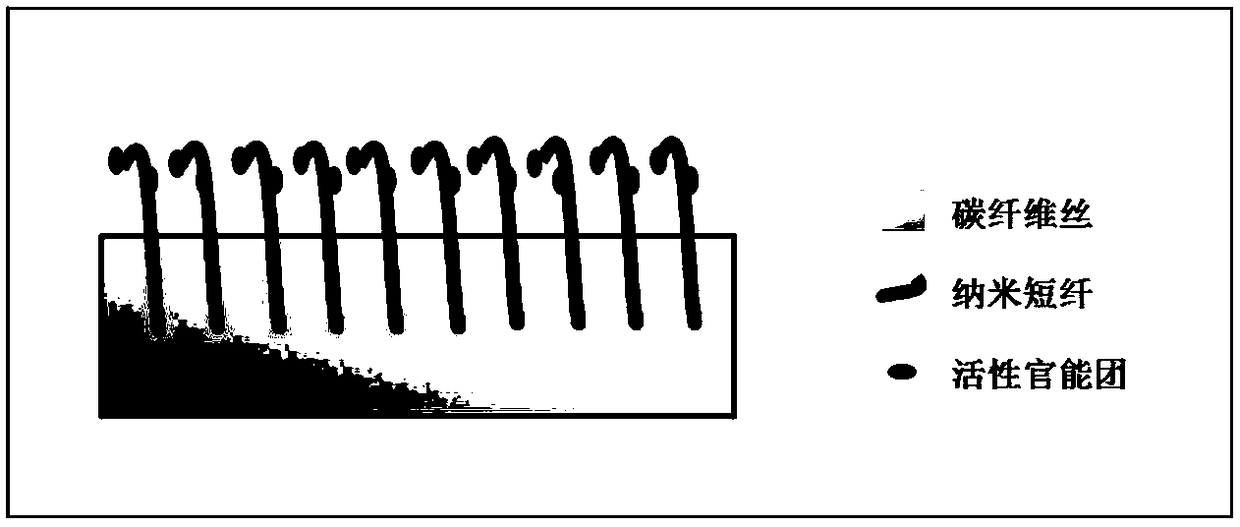

[0039] Through physical characterization, it is found that the nano-graphene oxide bonded on the surface of the carbon fiber is a flake-like structure, and most of them exist in a multi-layer graphene structure. ranging from tens of nanometers to hundreds of nanometers, such as image ...

Embodiment 2

[0041] In this embodiment, the multi-walled carbon nanotubes are dispersed in the Nafion / ethanol solution with a weight concentration of 0.02%, and the concentration is prepared into a dispersion liquid of 1.5wt.% multi-walled carbon nanotubes; then the polyacrylonitrile graphite felt is soaked In this dispersion liquid, after the absorption is complete, put it into an oven for drying. The temperature of the oven is 60°C, and the drying time is 6 hours; 2 The carbonization treatment is carried out in the atmosphere, the carbonization temperature is 1000°C, and the carbonization time is 3h. Finally, a high specific surface carbon fiber felt composite electrode decorated with multi-walled carbon nanotubes can be obtained.

[0042] Through physical characterization, it is found that the fiber surface of the composite electrode is relatively rough, and some carbon nanotubes are agglomerated into large-sized particles, while most of the carbon nanotubes are more uniformly dispersed ...

Embodiment 3

[0044] In this embodiment, the carbon fiber felt is soaked in a concentration of 1mol L -1 Ni(NO 3 ) 3 solution; then put it into an oven for drying, the temperature of the oven is 60°C, and the drying time is 6h; after drying, place it in H 2 The thermal reduction of the catalyst is carried out in the mixed gas of Ar / Ar, and the thermal reduction atmosphere is H with a molar ratio of 1:9. 2 / Ar mixed gas, the reduction temperature is 600°C, and the reduction time is 3h; then the chemical vapor deposition of carbon nanotubes and carbon nanofibers is carried out in the mixed gas of acetylene and hydrogen, wherein the molar ratio of acetylene and hydrogen is 1:25, and the deposition The temperature is 700°C, and the deposition time is 0.5h; it is carbonized at a temperature of 1000°C, and the carbonization time is 3h, and finally a high specific surface carbon fiber felt composite electrode modified by carbon nanotubes can be obtained.

[0045] Through physical characterizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com