Quick-plug connector and automotive pipeline system

A technology of plug-in connection and joint card, which is applied in the field of quick-plug connection joints and automobile pipeline systems, which can solve problems such as damage and deformation of quick-connect joints, poor sealing performance, and cracking of nylon pipe ends, and achieve the effect of reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

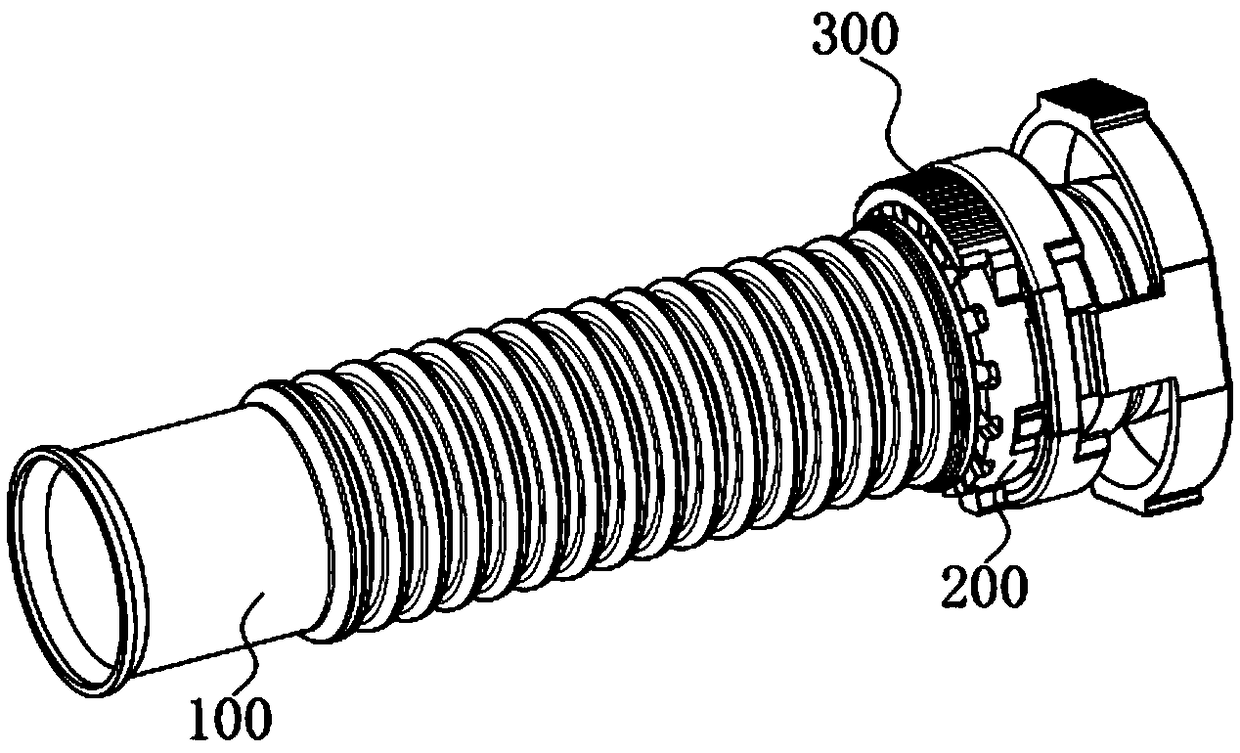

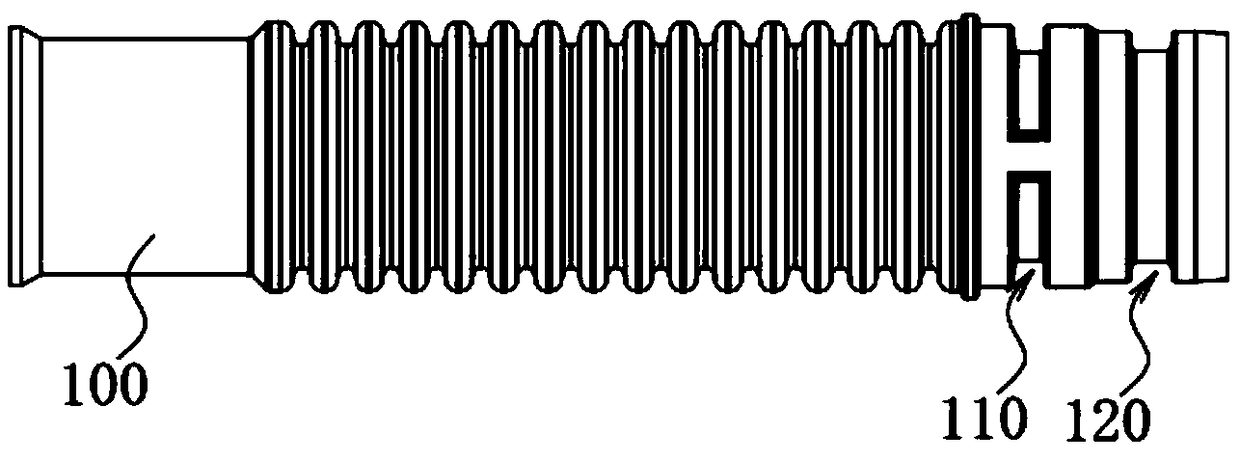

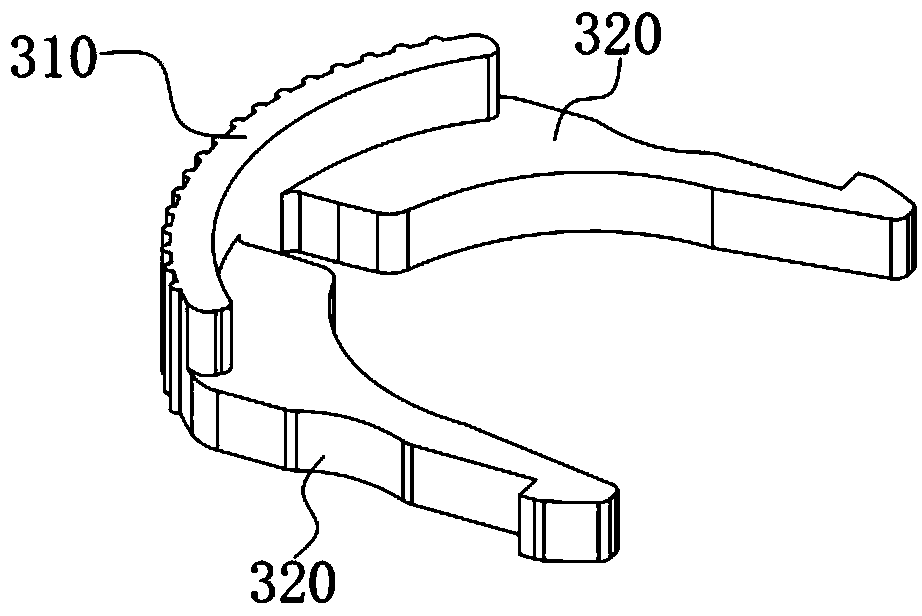

[0052] Such as Figure 1 to Figure 4As shown, the first embodiment provides a quick-plug connection joint, including: a first pipe body 100, a joint buckle 200 and a joint lock buckle 300; , the joint buckle 200 is fixedly sleeved on the first pipe body 100 , the joint lock 300 includes a fixing part 310 and elastic locking parts 320 connected to both ends of the fixing part 310 , and the elastic locking part 320 is located in the limiting slot 110 , and its end away from the fixing part 310 is engaged with the joint buckle 200 , and the first pipe body 100 is locked between the elastic locking parts 320 .

[0053] It should be noted that the first tube body 100 is a tube body required for connection, for example: the first tube body 100 is a nylon tube.

[0054] The following will be described by taking nylon tube as an example for the first tube body 100 .

[0055] In the quick-plug connection joint, the nylon tube is provided with a limit card slot 110, wherein the joint ...

Embodiment 2

[0082] Such as Figure 1 to Figure 7 As shown, the second embodiment provides an automobile pipeline system, including: the push-in connector in the first embodiment.

[0083] The automobile pipeline system includes the above-mentioned quick-connect connector, wherein the specific structure, connection relationship and beneficial effects of the quick-connect connector have been described in detail in the above text, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com