An electroslag welding anti-spill box structure and its processing method

A box-shaped structure and processing method technology, which is applied in the processing of box-shaped structures and the field of electroslag welding to prevent spillage of box-shaped structures, can solve the problem that the lining strip of the inner partition and the box-shaped cover cannot be tightly attached, and the size deviation of the inner partition can be solved. , Electroslag is easy to overflow and other problems, to achieve the effect of reducing expenditure and equipment investment, saving processing costs, and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

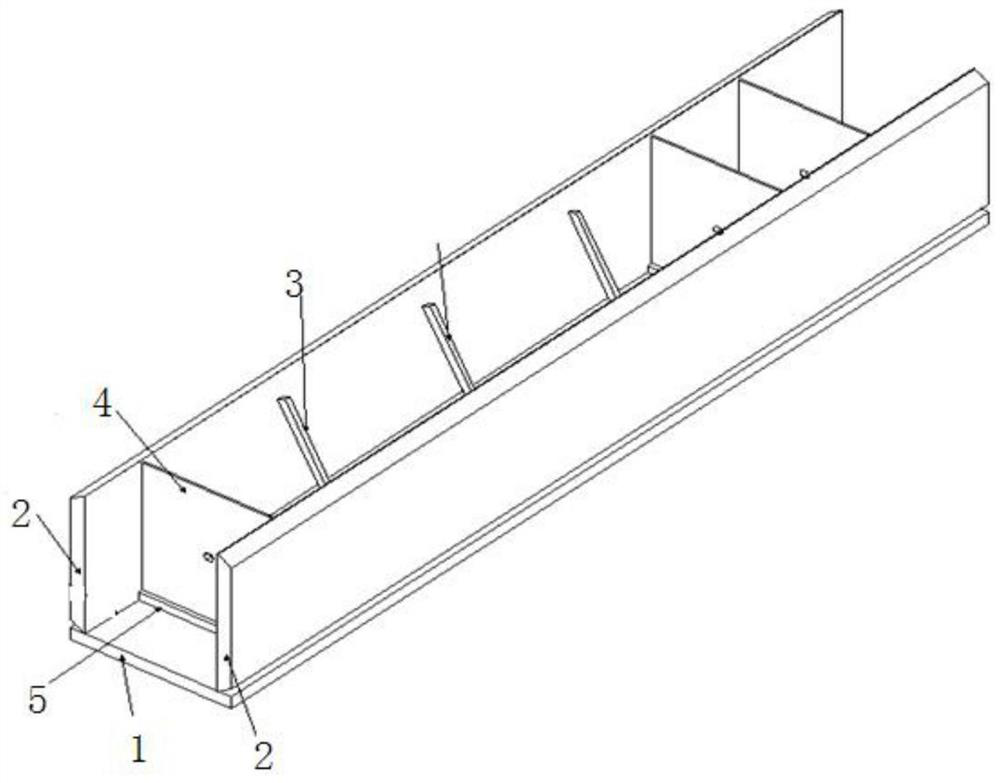

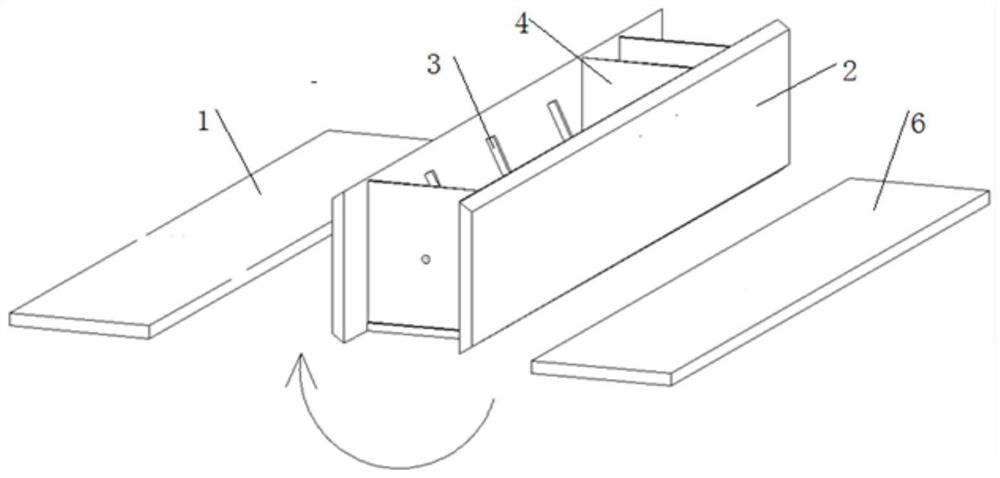

[0024] The present invention is an electroslag welding anti-spill box structure, such as figure 1 , figure 2 As shown, it includes an upper cover plate 1 and a lower cover plate 6 arranged in parallel, two webs 2 are arranged in parallel between the upper cover plate 1 and the lower cover plate 6, and the The support rods 3 and the inner partitions 4 are arranged at an angle on the web 2, and the position where each web 2 contacts with the upper cover 1 and the lower cover 6 is respectively provided with an electroslag welding liner 5, and each electroslag welding The lining plate 5 is closely attached to the inner surface of the upper cover plate 1, the lower cover plate 6 and the web plate 2; the web plate 2 is fixed between the upper cover plate 1 and the lower cover plate 6 by spot welding, and the inner partition plate 4 passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com