Modular motor with high slot fullness windings pre-wound for electric vehicles

An electric vehicle, pre-winding technology, applied in the shape/style/structure of electric vehicles, motors, winding conductors, etc., can solve the problems that have not been retrieved, achieve simple and reliable fixing, reduce iron loss, and reduce flux linkage effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention will be described in further detail below in conjunction with the accompanying drawings.

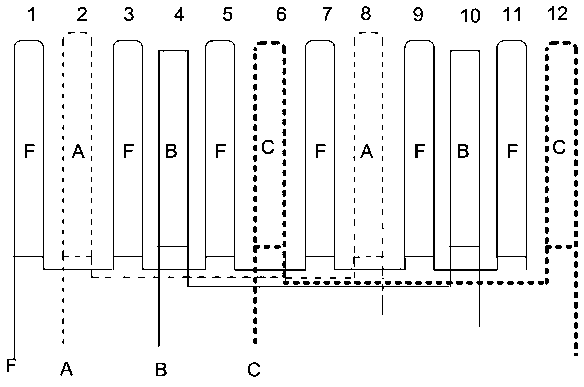

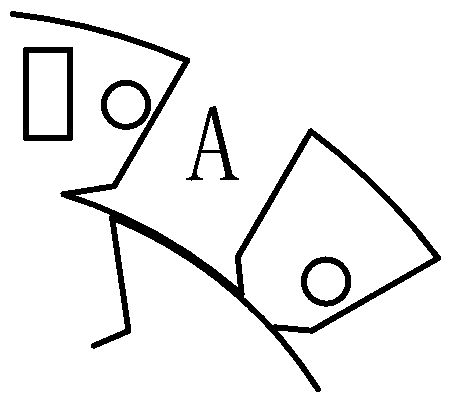

[0035] figure 1 It is a structural schematic diagram of a modular motor with pre-wound high-slot-full-rate windings for an electric vehicle of the present invention. Mark F is the pole where the field winding is located, and A, B, and C are the poles where the armature windings of phase A, B, and C are located, respectively.

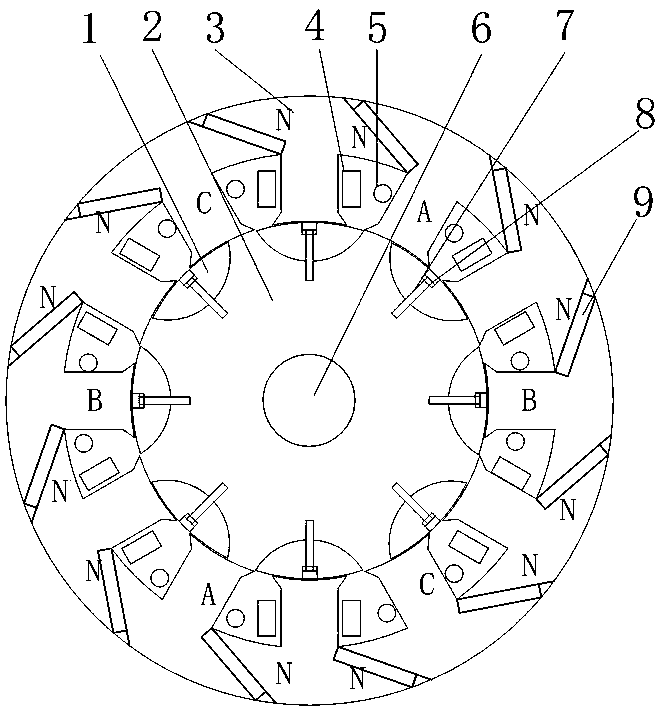

[0036] Including convex lens core, non-magnetic rotor core, stator core, field winding, armature winding, shaft, screw, pressing piece and permanent magnet;

[0037] There are 6X equal-width stator poles inside the stator core, and X is a positive integer; in this embodiment, X=2

[0038] The non-magnetic rotor core is located inside the stator core and fixed on the shaft; the non-magnetic rotor core has 8 arc-shaped grooves; the arc-shaped grooves are embedded with a convex lens-shaped core made of laminated silicon steel sheets, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com