A battery mounting device for an electric vehicle

A battery installation device, electric vehicle technology, applied in electric vehicles, electric power devices, power devices and other directions, can solve the problems of heavy weight, troublesome installation and disassembly, large battery volume, etc., and achieve the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

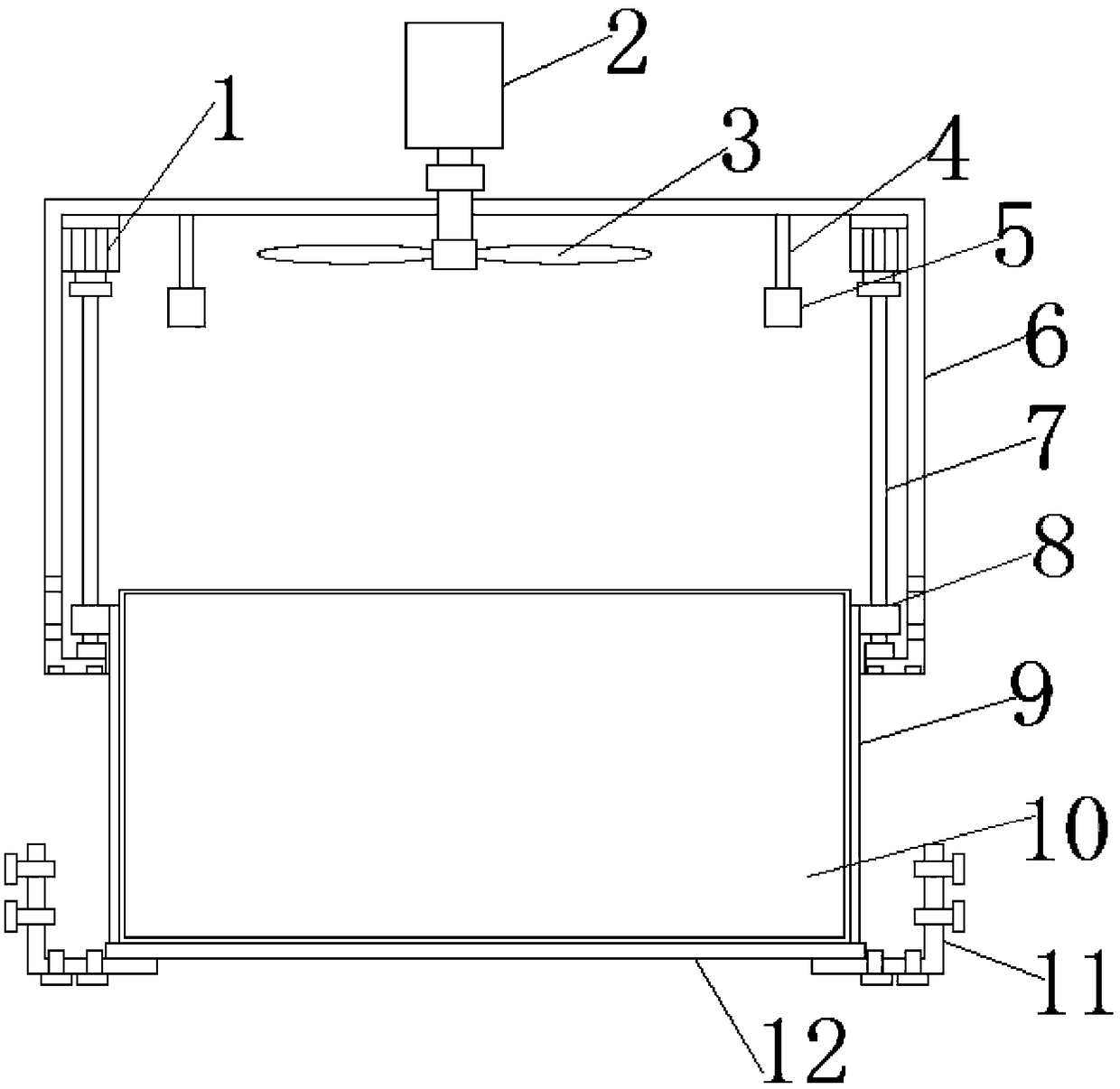

[0022] see Figure 1~2 , a battery installation device for electric vehicles, comprising a first motor 1, a second motor 2, a fan body 3, a fixed rod 4, a fixed frame 5, a mounting box 6, a screw rod 7, a nut seat 8, a lifting box 9, a battery Box 10, mounting bracket 11 and sealing support plate 12, the first motor 1 is installed at the four corner positions of the top plate bottom surface of the installation box 6, and the rotating shaft of the first motor 1 is fixedly connected with a shaft coupling and a screw rod 7 at one end , the screw mandrel 7 is vertically arranged, and the other end of the screw mandrel 7 is fixed on the corner of the base plate top surface of the installation box 6 with a fixed bearing, the screw mandrel 7 is equipped with a nut seat 8, and the screw mandrel 7 and the nut seat 8 above it Threaded connection, the four nut seats 8 inside the installation box 6 are fixedly connected to the top ends of both sides of the lift box 9 respectively, the fro...

Embodiment 2

[0025] see Figure 5-10 A type of battery pack is fixed inside the battery box 10, and the type of battery pack includes two opposite circular connection plates 1-1-11, and a through hole is provided in the middle of the connection plate 1-1-11 A plurality of concentric circular grooves 1-1-12 are arranged on the opposite end surfaces of the two connecting plates 1-1-11, and the two ends of the cylindrical heat sink 1-1-14 are respectively inserted into the two circular connecting plates In the groove 1-1-12 of 1-1-11; the bottom of the groove is provided with a strip-shaped guide hole, and the end of the heat sink 1-1-14 is provided with a protruding strip-shaped guide piece, and the guide piece passes through into the guide hole; the guide hole communicates with the water guide hole 1-1-13 arranged along the radial direction on the side wall of the circular connecting plate 1-1-11; a seal is set between the guide piece and the inner surface of the guide hole ring or apply s...

Embodiment 3

[0030] see Figure 3-4 , the battery box 10 is fixed with a second-type battery pack, the second-type battery pack is a rectangular parallelepiped shape formed by contacting the two sides of a plurality of batteries, and the second-type battery pack is placed in a cooling box suitable for its shape In the body 2-10, the cooling box 2-10 includes a ventilation casing 2-11 with openings on the top and bottom, and a honeycomb support 2-12 is arranged inside the ventilation casing 2-11, and the diamond-shaped space of the support 2-12 is The battery 1-1-18 is inserted inside, and the bottom of the bracket 2-12 is connected with the upper surface of the stop plate 2-13 by snapping or bonding, and the upper surface of the stop plate 2-13 is connected with the battery 1-1-18 A through ventilation hole is provided at the contact position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com