Box self-unloading device

A technology of self-unloading device and carriage, applied in the direction of vehicles with endless chain/ring belt, etc., can solve the problem of high cost of unloading and loading, and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

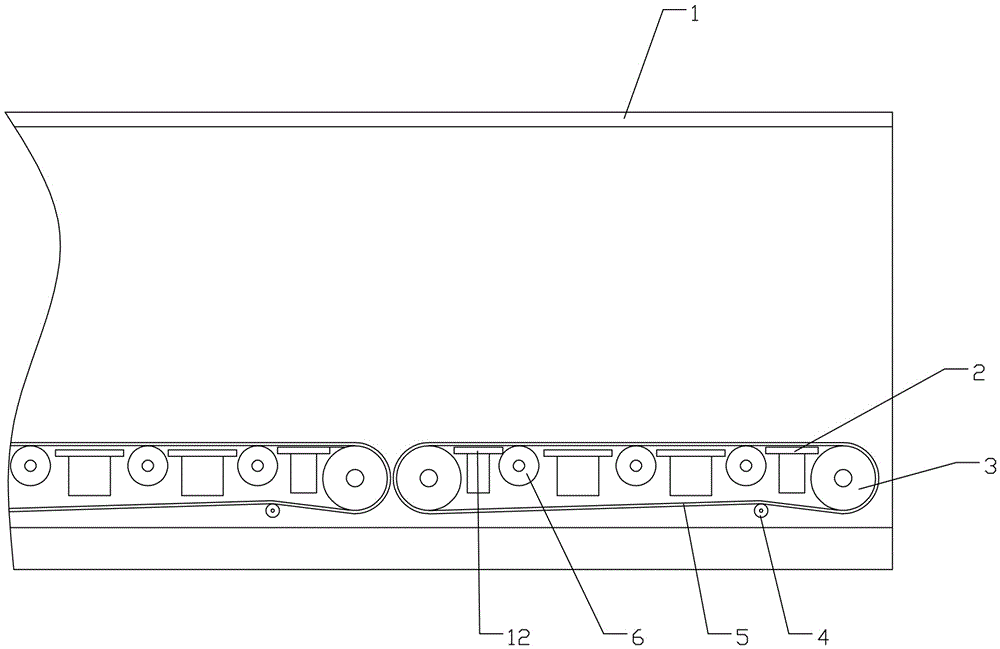

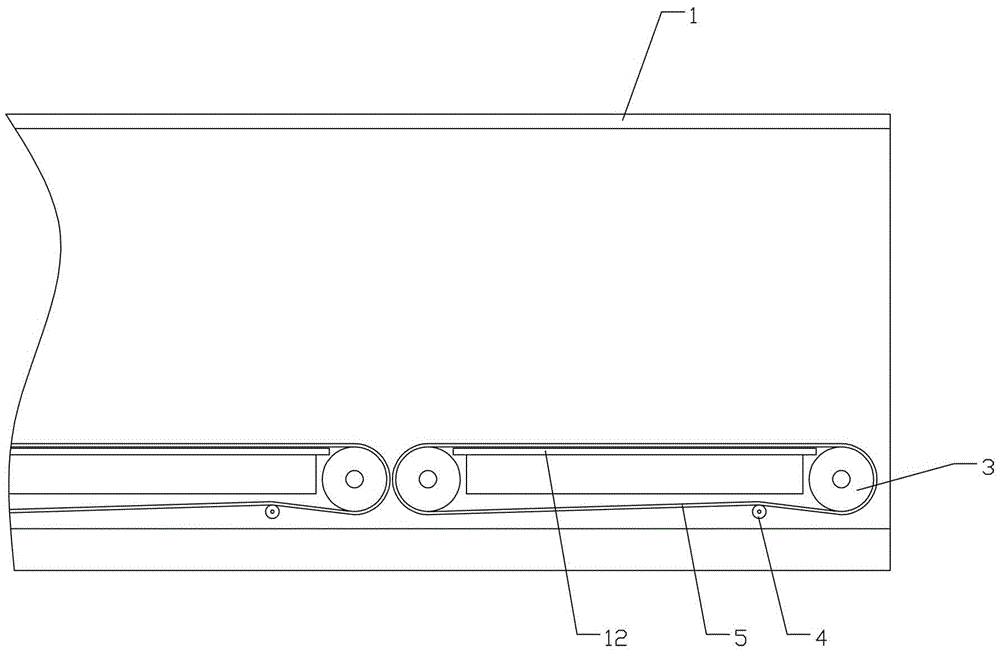

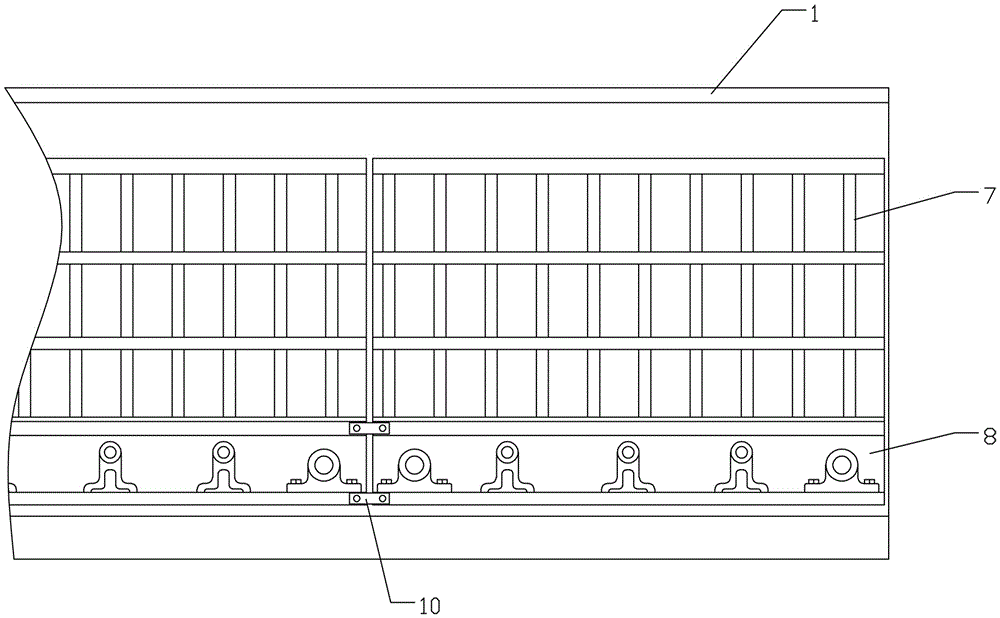

[0026] The compartment self-unloading device includes a multi-section belt conveyor floor 2 that can be spliced front and rear and is arranged on the floor of the compartment 1. Guard plates 7 are arranged on both sides of the belt conveyor floor 2, and the guard plates 7 and the belt conveyor floor 2 The plane where it is located forms an obtuse angle greater than 90 degrees and relies on the inner side walls of the compartment 1. A hinge 10 is provided between the guard plate 7 and the belt conveyor floor 2, and the guard plate 7 can be placed flat on the belt conveyor floor 2 around the hinge 10. The belt conveying floor 2 which can be spliced front and back is connected by connecting buckles at both sides.

[0027] The belt conveyor floor 2 includes driving wheels 3 arranged front and rear and a conveyor belt 5 around the front and rear driving wheels 3 , and a tensioning system 4 is provided on the lower part of the outer surface of the conveyor belt 5 .

[0028] Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com