Container with sliding column type tail board

The technology of a cargo box and a tail plate is applied in the field of the cargo box structure with a sliding column type tail plate, which can solve the problems of high manufacturing cost, large space occupation, complicated structure of the driving device, etc., and achieves compact structure, simple structure, and reduced quantity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

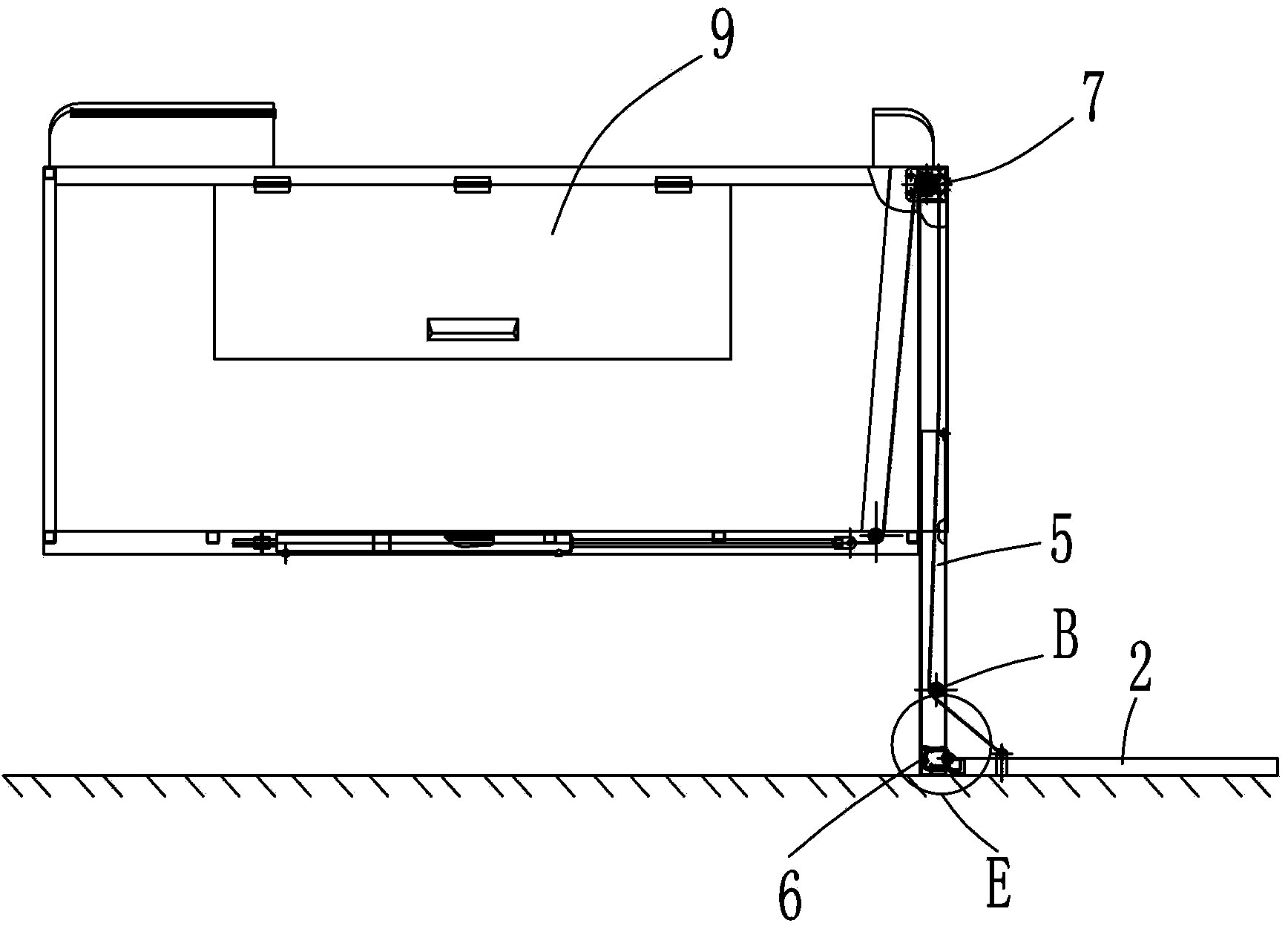

[0018] combine figure 1 —— figure 2 The shown cargo box with a sliding column tail plate consists of a cargo box body 1, a tail plate 2, a tensioning cylinder 3, a chain 4, a vertical sliding column 5, a sliding column locking mechanism 6, a sprocket 7, and a fastening plate 8 , Side door 9, hinge shaft A, first fixed shaft B, second fixed shaft C, lock catch and so on.

[0019] There are two up and down sliding columns 5 between the cargo box body 1 and the tail plate 2, and there are two up and down sliding columns 3, which are arranged on the left and right sides of the cargo box 2 tail. The lower end of the tail plate 2 and the lower end of the up and down sliding column 5 are hinged together through a hinge A, and a sliding column locking mechanism 6 is arranged in the up and down sliding column 5 . When the tailgate 2 is closed, the sliding column locking mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com