High-precision automatic FPC (Flexible Printed Circuit) binding equipment

A high-precision, automatic technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as increasing product defect rate, increasing cost, and inability to guarantee alignment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

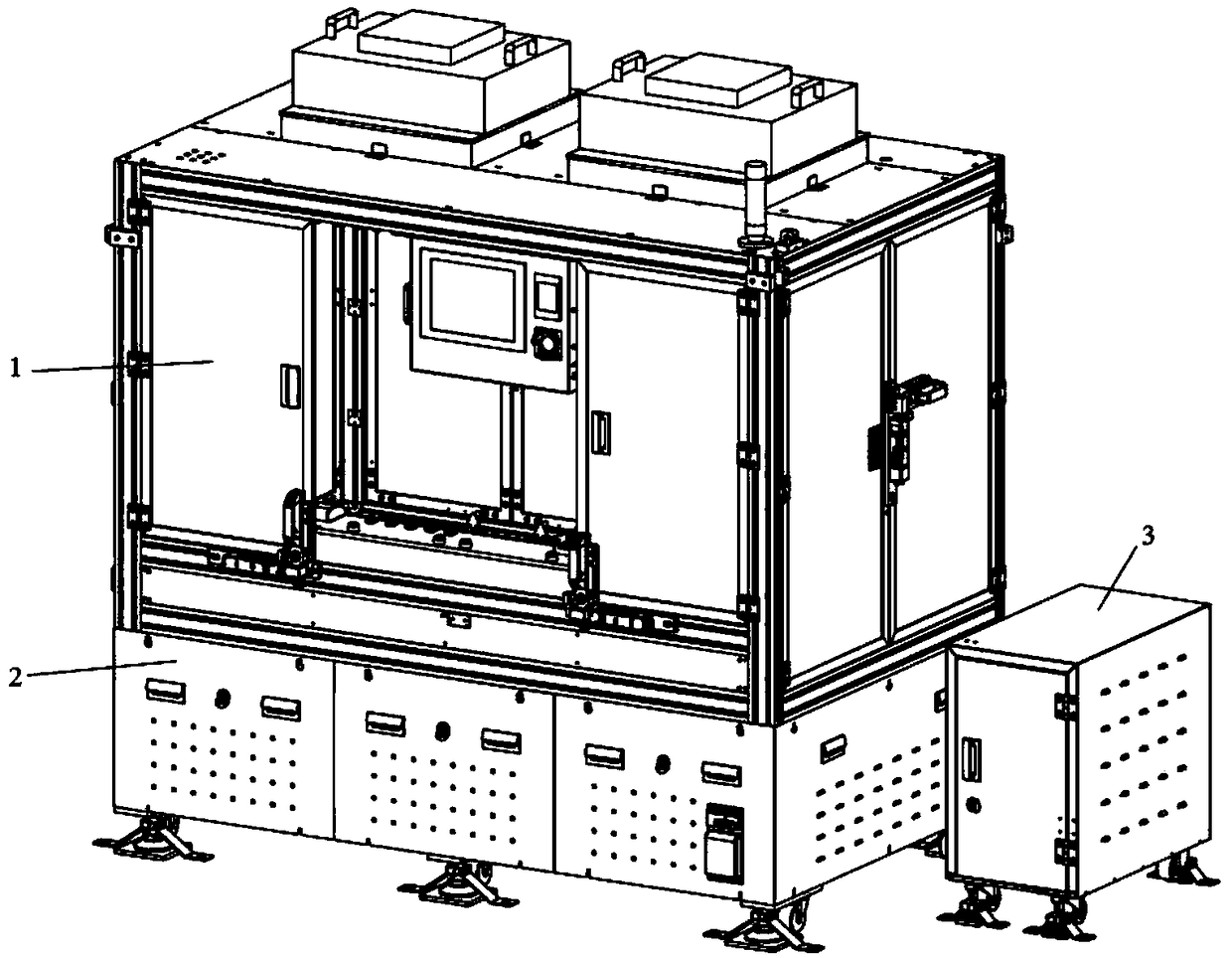

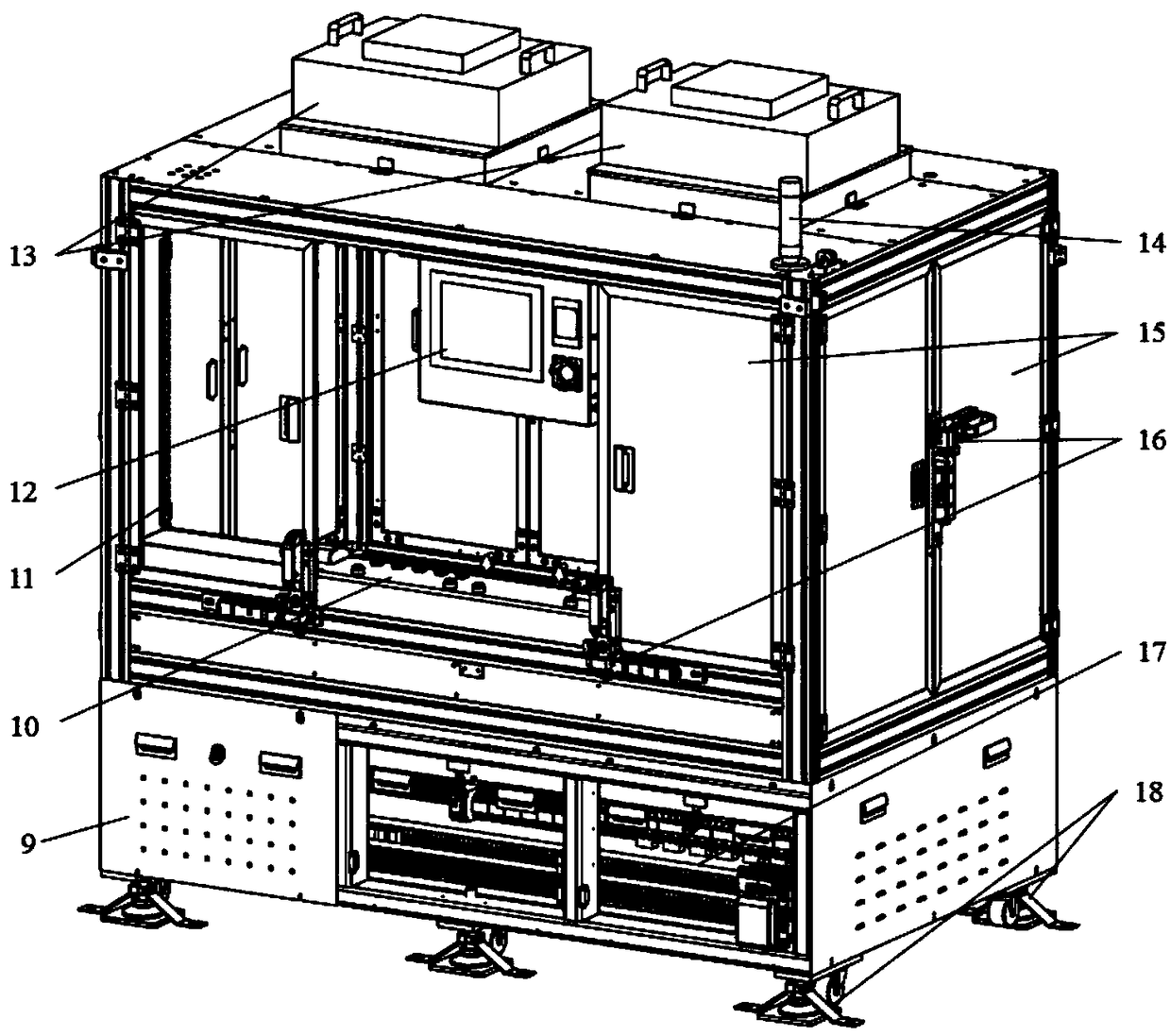

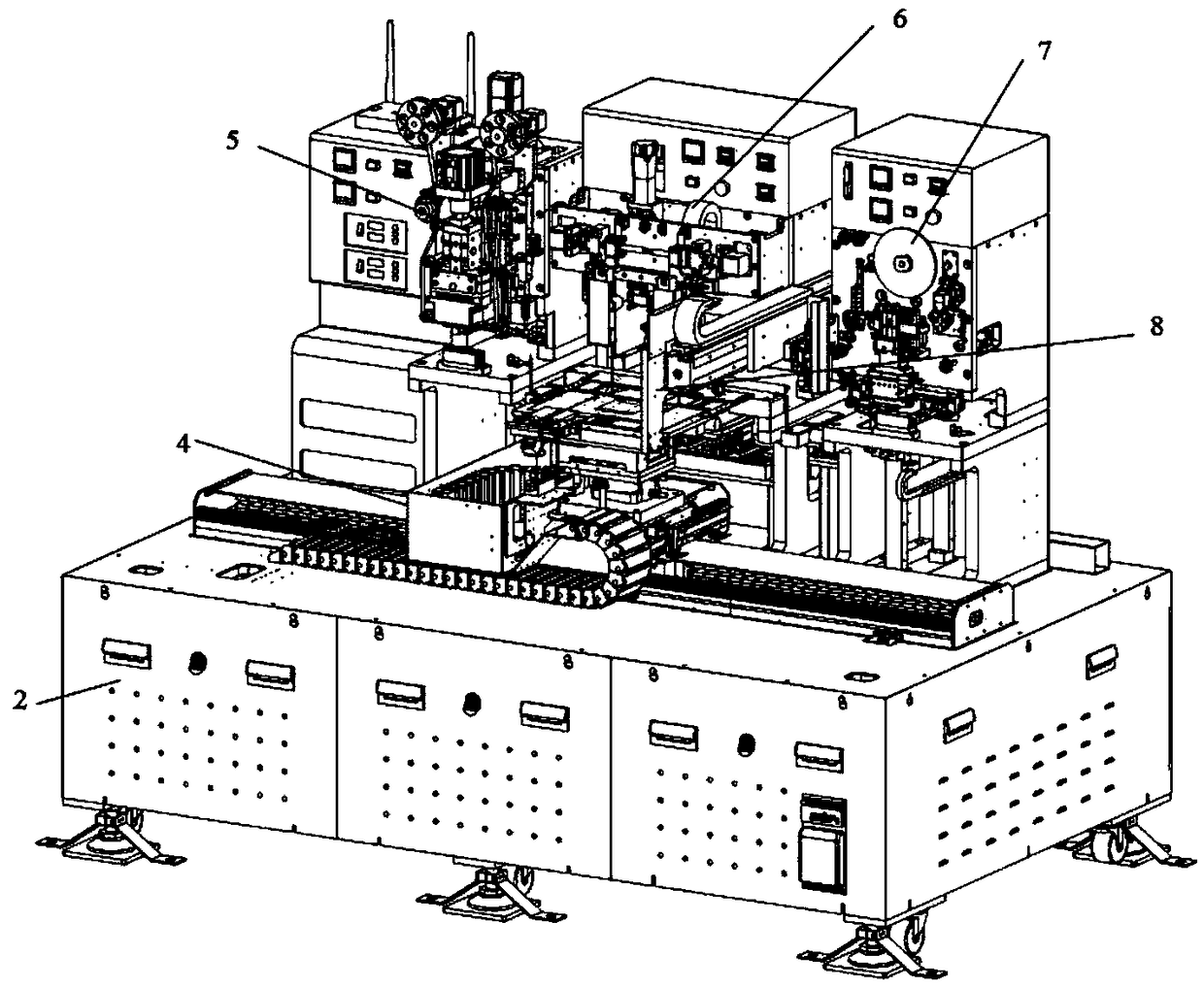

[0050] see Figure 1 to Figure 3 , the high-precision automatic FPC binding device in this embodiment includes an upper frame 1, a lower frame 2 and a UPS uninterruptible power supply 3, and is characterized in that: it also includes an ACF attachment mechanism 7, an FPC pre-pressing mechanism 6, an FPC This pressure mechanism 5, the FPC feeding platform mechanism 8 and the four-axis adjustment conveying platform mechanism 4; the upper frame 1 and the lower frame 2 are connected to form the equipment body, the UPS uninterruptible power supply 3 is connected to the internal circuit of the equipment body from the outside, and the FPC The pressing mechanism 5, the FPC pre-pressing mechanism 6 and the ACF attaching mechanism 7 are sequentially arranged on the horizontal workbench of the lower frame 2, the FPC feeding platform mechanism 8 is connected with the ACF attaching mechanism 7, and the four-axis adjustment conveying platform mechanism 4 is set on the horizontal workbench o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com