Compact track two-dimensional and three-dimensional imaging system

A three-dimensional imaging, compact technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., to reduce weight, adapt to a wide range, and ensure the effect of two-dimensional imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

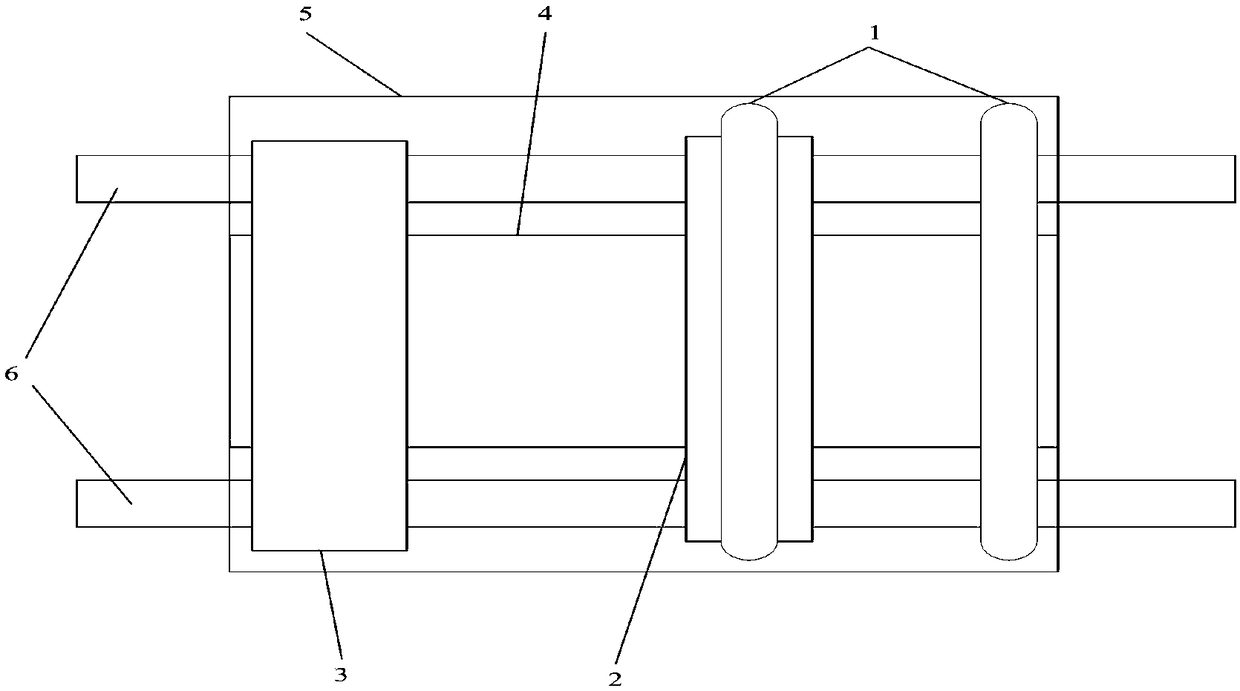

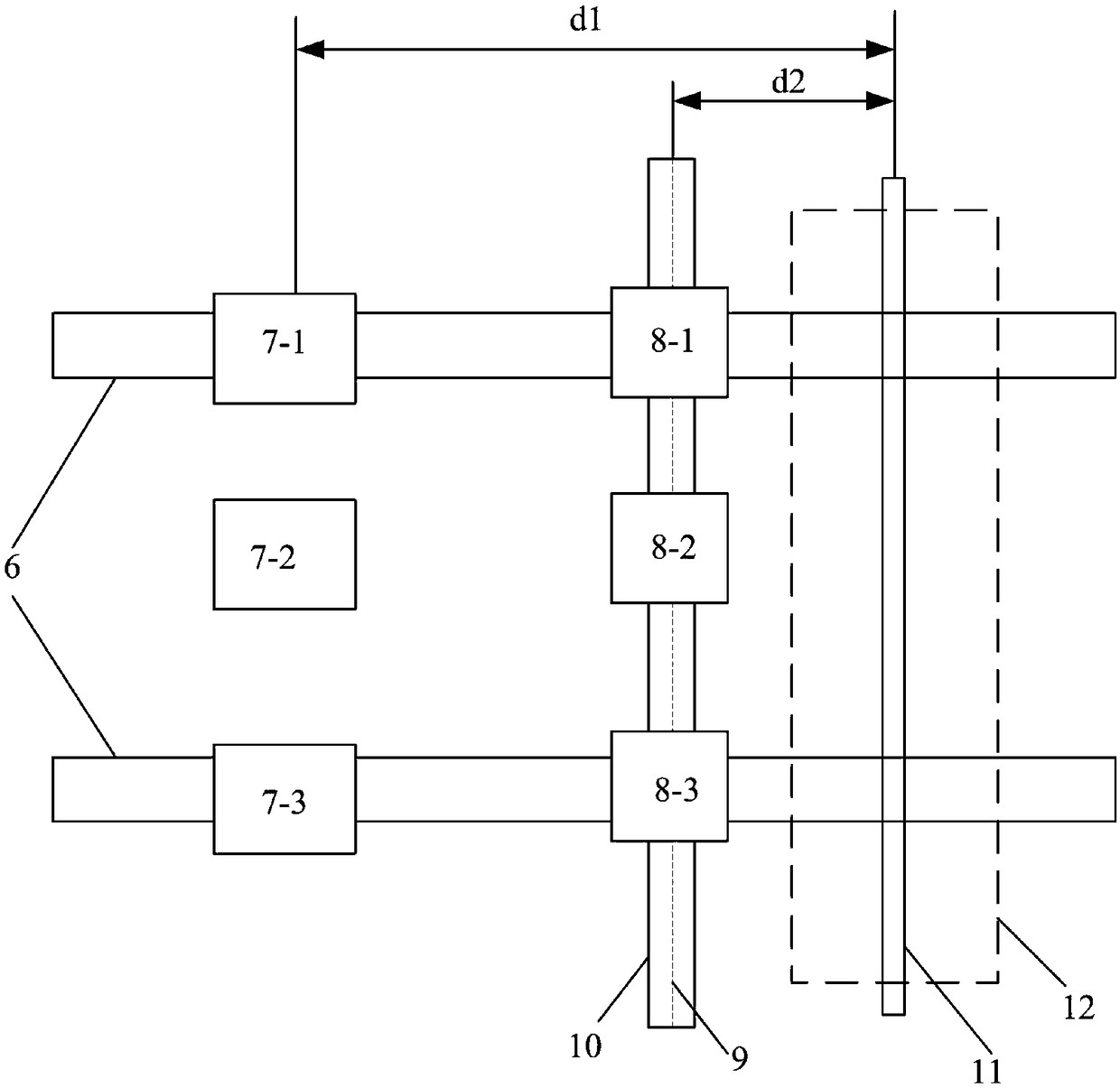

[0044] The 3D imaging unit, the slice light P2 and the line array imaging unit, the slice light P1 are sequentially arranged longitudinally along the track. Such as figure 2 As shown, the 3D imaging unit is composed of three 3D cameras 7, and the three 3D cameras are arranged vertically along the longitudinal direction of the track, wherein the 3D cameras 7-1 and 7-3 are located directly above the rail, and the 3D camera 7-2 is located directly above the center of the rail , the imaging field of view of the 3D cameras has overlapping areas to perform 3D imaging on the entire track; the angle between the optical axes of the three 3D cameras 7 and the sheet light PI is 45 degrees, and the optical centers of the 3D cameras 7 extend along the track to the sheet light PI The distance of P1 is d1, and the value of d1 is 500mm; the line array imaging unit is composed of three line array cameras 8, wherein the line array cameras 8-1 and 8-3 are located directly above the rail, and th...

Embodiment 3

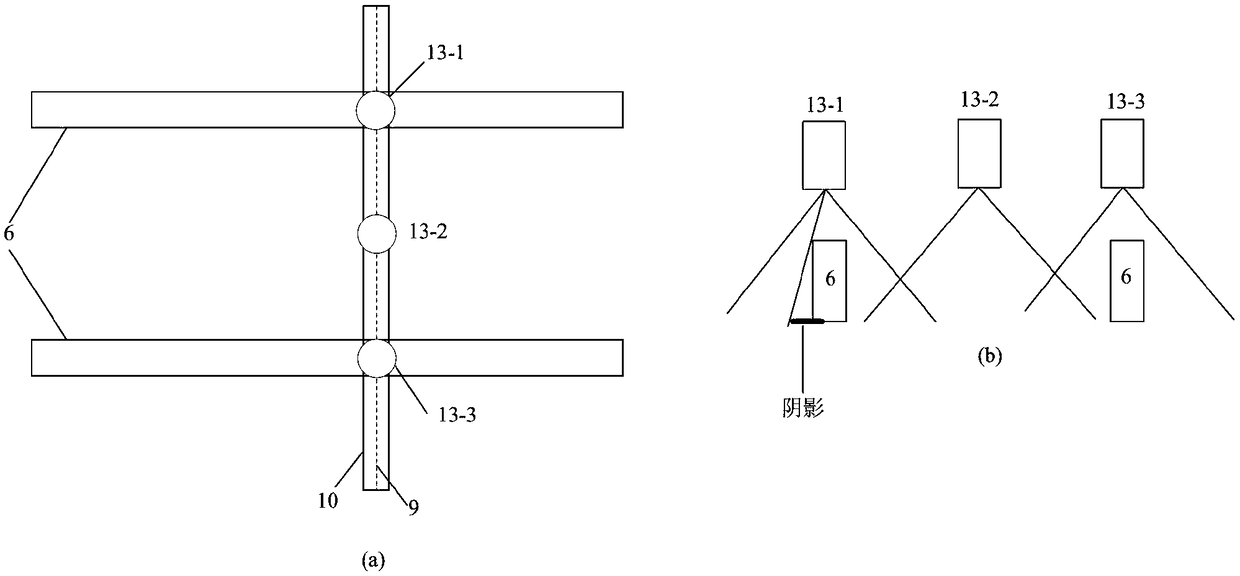

[0051] The difference from Example 2 is that, as Figure 5 As shown, the sheet light P2 is composed of five line light sources 13 collinearly spliced together, wherein the line light sources 13-1, 13-2, 13-4, and 13-5 are respectively located on both sides above the rail, and 13-3 is located above the center of the track ;Such as Figure 6 As shown, the sheet light P1 is composed of 5 linear structured light generators 14 co-linearly spliced together, of which 4 linear structured light generators 14-1, 14-2, 14-4, 14-5 are respectively located on both sides above the rail , a line structured light generator 14-3 is located above the center of the track. The advantage of this is that if Figure 4 As shown, in the sheet light P2 in Embodiment 2, when the line light source 13-1 or 13-3 is located directly above the rail, shadows will be generated due to the obstruction of the rail. Similarly, for the sheet light P1 in Embodiment 2, when the line structured light generators...

Embodiment 4

[0053] The difference from Embodiment 3 is that the light sheets P1 and P2 are near-infrared light sources with a wavelength of 808nm, and an 808nm narrow-band filter is installed at the front end of the line array camera 8 and 3D camera 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com