Electromagnetic spinning type split-Hopkinson torsional bar

A press-rotary, electromagnetic technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that bending waves are difficult to eliminate, long-term, and loading torque cannot be accurately controlled, so as to reduce the difficulty of experiments and improve the efficiency of experiments. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further clarified below in conjunction with specific drawings.

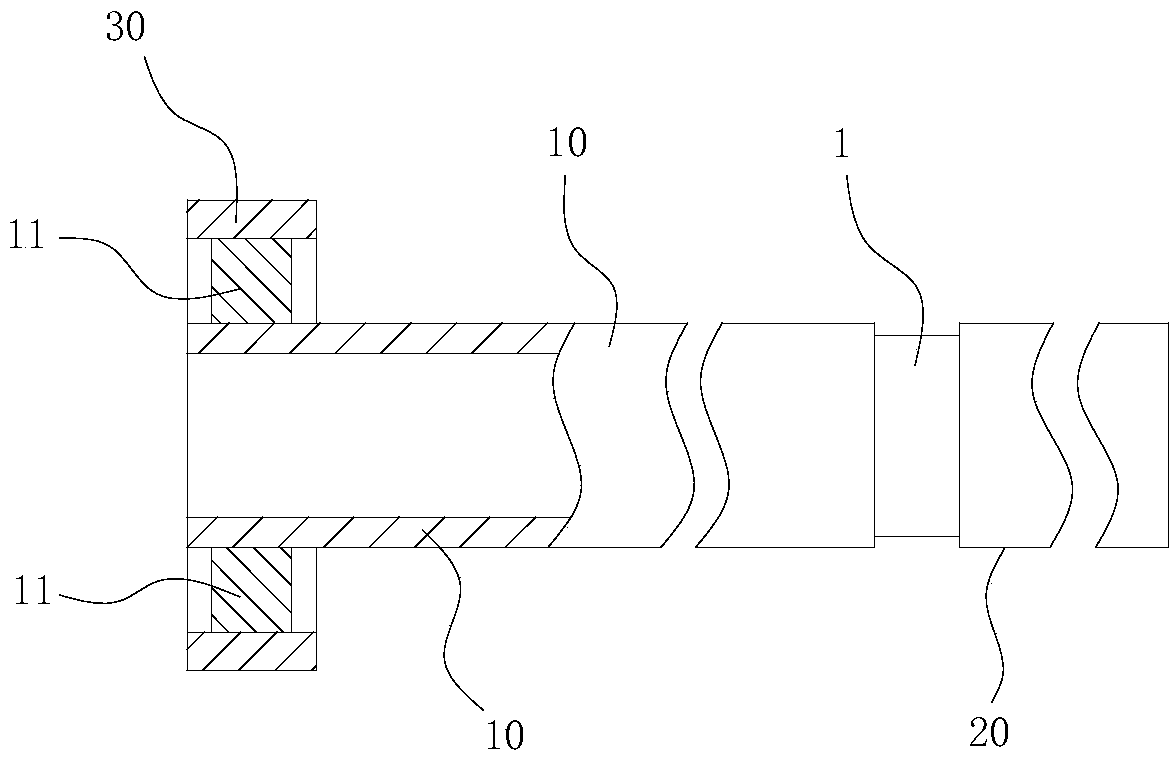

[0019] combine figure 1 , 2 As shown, the present invention provides an electromagnetic pressure-rotating Hopkinson torsion bar, including an incident rod 10, a transmission rod 20, and a test piece 1 placed at the adjacent ends of the incident rod 10 and the transmission rod 20; Cylindrical fixed frame 30, said fixed frame 30 is coaxially arranged on the overhanging end of incident rod 10, said incident rod 10 is fixed with a number of rotating blades 11, said rotating blades 11 are arranged on the fixed frame The pulse type electromagnetic loader 40 inside the 30 is pushed, and the pulse type electromagnetic loader 40 is electrically connected with the transient power supply group and the control unit 50 .

[0020] The transient power supply grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com