Compression test method for honeycomb SCR catalyst

A technology of SCR catalyst and testing method, which is applied in the field of compressive testing of honeycomb SCR flue gas denitrification catalyst, can solve the problems of broken samples, large errors in measurement results, unfavorable sample recovery and disposal, etc., so as to avoid broken and maintain Integrity, effect of saving stakeout time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

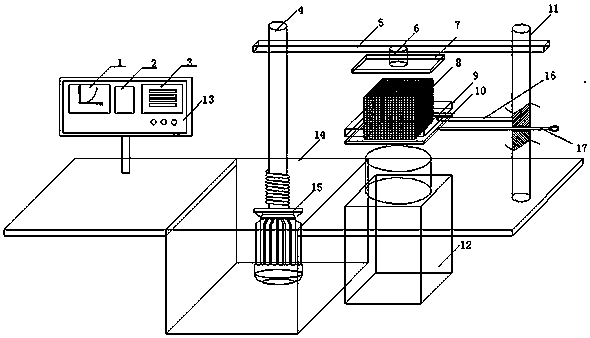

[0025] The structure of the pressure testing machine used in a kind of honeycomb SCR catalyst compression test method of the present embodiment is as follows figure 1 As shown, it includes an industrial computer 13 , a machine platform 14 , a motor 15 , a screw mandrel 4 , a suspension rod 5 , a pressure sensor 6 , an upper platen 7 , a lower platen 10 and a guide post 11 .

[0026] In this embodiment, the motor 15 is arranged in the machine platform 14, the output end of the motor 15 is connected with the screw mandrel 4, and one end of the suspension rod 5 is provided with a threaded hole cooperating with the screw mandrel 4, and the suspension rod 5 is rotatably connected with the screw mandrel 4 through the threaded hole , the other end of the suspension rod 5 is provided with a through hole matched with the guide column 11, the suspension rod 5 is slidably connected with the guide column 11 through the through hole, and one end of the guide column 11 is fixed on the machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com